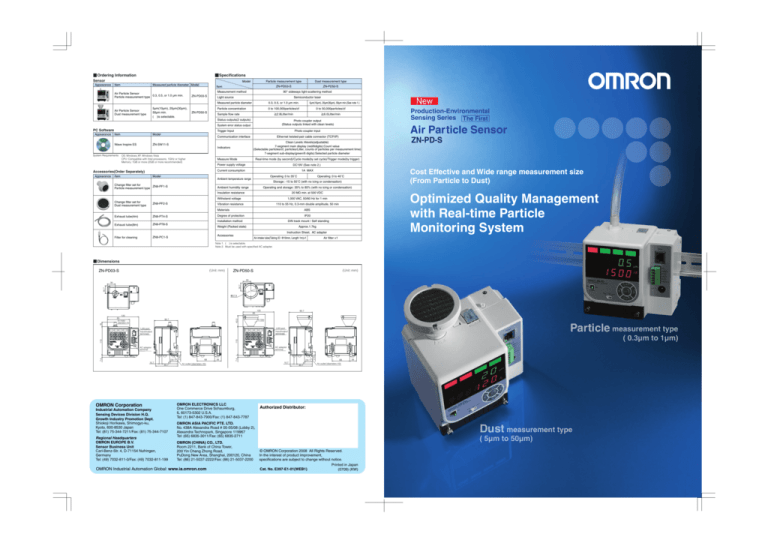

Ordering Information

Specifications

Sensor

Model

Appearance

Item

Measured particle diameter Model

Air Particle Sensor

Particle measurement type 0.3, 0.5, or 1.0 µm min.

5µm(10µm), 20µm(30µm),

50µm min.

( )is selectable.

Air Particle Sensor

Dust measurement type

Particle measurement type

Dust measurement type

ZN-PD03-S

ZN-PD50-S

Item

Measurement method

ZN-PD03-S

ZN-PD50-S

90° sideways light-scattering method

Semiconductor laser

Light source

Measured particle diameter

0.3, 0.5, or 1.0 µm min.

Particle concentration

0 to 100,000particles/cf

Sample flow rate

Trigger Input

Item

Model

Wave Inspire ES

ZN-SW11-S

System Requirements

Measure Mode

DC19V (See note 2.)

Current consumption

Item

Model

Operating and storage : 35% to 85% (with no icing or condensation)

Exhaust tube(4m)

ZN9-PT4-S

Vibration resistance

110 to 55 Hz, 0.3-mm double amplitude, 50 min

Materials

IP20

Installation method

DIN track mount / Self standing

Weight (Packed state)

Approx.1.7kg

Instruction Sheet, AC adapter

Accessories

ZN9-PC1-S

Filter for cleaning

ABS

Degree of protection

ZN9-PT8-S

Exhaust tube(8m)

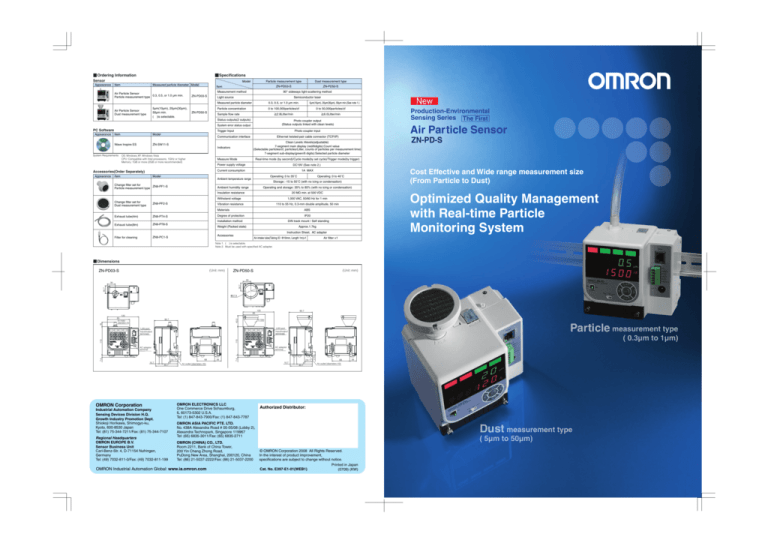

Optimized Quality Management

with Real-time Particle

Monitoring System

20 MΩ min. at 500 VDC

1,000 VAC, 50/60 Hz for 1 min

Withstand voltage

ZN9-PF2-S

Operating : 0 to 40˚C

Storage : -15 to 50˚C (with no icing or condensation)

Ambient humidity range

Insulation resistance

Change filter set for

Dust measurement type

Cost Effective and Wide range measurement size

(From Particle to Dust)

1A MAX

Operating : 0 to 35˚C

Ambient temperature range

Change filter set for

ZN9-PF1-S

Particle measurement type

ZN-PD-S

Real-time mode (by second)/Cycle mode(by set cycle)/Trigger mode(by trigger)

Power supply voltage

Accessories(Order Separately)

Appearance

Clean Levels:4levels(adjustable)

7-segment main display (red/6digits):Count value

(Selectable particles/cf, particles/Litter, counts of particles per measurement time)

7-segment sub-display(green/6 digits):Selected particle diameter

Indicators

OS:Windows XP, Windows Vista

CPU:Compatible with Intel processors, 1GHz or higher

Memory: 1GB or more (2GB or more recommended)

Air Particle Sensor

Photo coupler input

Ethernet twisted-pair cable connector (TCP/IP)

Communication interface

New

Production-Environmental

Sensing Series The First

6.0Litter/min

Photo coupler output

(Status outputs linked with clean levels)

System error status output

Appearance

0 to 50,000particles/cf

2.8Litter/min

Status outputs(2 outputs)

PC Software

5µm(10µm), 20µm(30µm), 50µm min.(See note 1.)

Air-intake tube(Tubing ID : Φ10mm, Length 1m)×1

Air filter ×1

Note 1. ( ) is selectable.

Note 2. Must be used with specified AC adapter.

Dimensions

(Unit:mm)

ZN-PD03-S

(Unit:mm)

ZN-PD50-S

30

30.7

30.7

30

Φ57.9

120

85

Air intake

(diameter=10)

43.3

90.7

Air intake

Particle measurement type

LAN port

Input/output

terminals

( 0.3µm to 1µm)

110

110

LAN port

Input/output

terminals

AC adaptor

terminal

(30.7)

61

85.7

OMRON Corporation

Industrial Automation Company

Sensing Devices Division H.Q.

Growth Industry Promotion Dept.

Shiokoji Horikawa, Shimogyo-ku,

Kyoto, 600-8530 Japan

Tel: (81) 75-344-7211/Fax: (81) 75-344-7107

Regional Headquarters

OMRON EUROPE B.V.

Sensor Business Unit

Carl-Benz-Str. 4, D-71154 Nufringen,

Germany

Tel: (49) 7032-811-0/Fax: (49) 7032-811-199

68

26

7.4

10.7

(14)

7.4

AC adaptor

terminal

Air outlet (diameter=10)

OMRON ELECTRONICS LLC

One Commerce Drive Schaumburg,

IL 60173-5302 U.S.A.

Tel: (1) 847-843-7900/Fax: (1) 847-843-7787

10.7

(30.7)

61

85.7

(14)

18

90.7

85

120

68

26

Air outlet (diameter=10)

Authorized Distributor:

OMRON ASIA PACIFIC PTE. LTD.

No. 438A Alexandra Road # 05-05/08 (Lobby 2),

Alexandra Technopark, Singapore 119967

Tel: (65) 6835-3011/Fax: (65) 6835-2711

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower,

200 Yin Cheng Zhong Road,

PuDong New Area, Shanghai, 200120, China

Tel: (86) 21-5037-2222/Fax: (86) 21-5037-2200

OMRON Industrial Automation Global: www.ia.omron.com

Dust measurement type

( 5µm to 50µm)

© OMRON Corporation 2008 All Rights Reserved.

In the interest of product improvement,

specifications are subject to change without notice.

Printed in Japan

Cat. No. E397-E1-01(WEB1)

(0709) (KW)

Optimized Quality

Management with

Two valuable

Models!

Particle/contamination

Real-time Monitoring

ALL NEW

Ambient Dust

Real-time Monitoring

Thinking of upgrading from manual fixed-point particle measurement in your clean

environment to a continuous monitoring solution?

The ZN-PD03-S Particle Sensor (Particle Type) provides continuous high-precision

monitoring at a very low set-up cost.

It is ideal for traceability and fault analysis and substantially reduces labor expenses.

Foreign matter in the production environment can affect the quality of finished products.

Perhaps your production environment is affected by dust? The largest form of particles,

typically carried by human operators and generated by machinery.

The ZN-PD50-S Particle Sensor (Dust measurement type) provides the most simple

and effective solution yet for monitoring dust levels.

Combines high-precision measurement

with continuous monitoring

Measurement accuracy to rival a particle counter?

Measure dust levels and identify dust

sources with a single unit

Industry First

Top

In Class

The Particle Sensor generates air flow of 2.83 liters per minute through a combination of

fully rectified internal design and high-suction fan. Measurement accuracy is close to

that of a particle counter, thanks to Omron laser-optic design technology as used in

high-precision displacement sensors.

Measured value (particles/cF)

Typical air cleanliness readings from different types

of measuring devices

600

ZN-PD-S

Particle counter

Conventional particle sensor

ZN-PD-S detects fluctuations

in cleanliness even in very

clean environments

500

400

Dust Catcher feature to

identify dust sources

The combination of a powerful fan and

a funnel-shaped air intake efficiently

captures falling dust. A built-in filter

prevents large dust particles from

entering the system and causing

internal blockages. The filter is simple

to replace.

Double-sided tape on the pull-out Trap Box

captures dust particles. The dust can then be

analyzed under a microscope to determine

the source.

Model ZN-PD03-S

300

0.3 µm 0.5 µm 1.0 µm

200

100

0

Particle measurement type

Efficient measurement of

falling dust

Trap Box

Simultaneous real-time sensing

0:00

0:10

0:20

0:30

0:40

0:50

1:00

1:10

Filter

Time (hr:min)

Intake air is irradiated with laser light

and the level of scattered light from

particles is measured.

Cleanliness levels varied in a CLASS 100 (approx.) environment

using FFU air flow control.

Particle sensor measurements taken via scaling.

Examples of use

Examples of use

Low-maintenance design

for continuous measurement

The maintenance workload is reduced substantially

through a combination of long-lasting fan construction and intermittent laser mode designed to

prolong the life span of the laser. Maintenance

costs are also much lower since the Particle Sensor

does not need an external pump which tends to

require frequent replacement.

Dust measurement type

Model ZN-PD50-S

5(10)µm 20(30)µm 50µm

Simultaneous real-time sensing

Multi-point continuous monitoring in clean room

Dust monitoring on paint process

Trend monitoring of manufacturing equipment

Measurement data is used for trend analysis and

early detection of problems

Connects readily to Ethernet hub for

networking with computers

Trend monitoring in cell manufacturing production line

Production-Environments Visualizer (PC software)

Option Model ZN-SW11-S

Real-time analysis of

measurement data

Diagram layout of equipment

and measuring devices

Convert selected data to

Excel format

Computer

Pop-up alarm window

LAN Port

Input/output

terminals

Supports trigger input as well as two-stage alarm and

error outputs.Can be configured to begin measurement

as required in response to trigger input and to generate

alarms in accordance with monitoring levels.

Scalable to particle diameter size

LAN

or

PLC

EtherNet hub

Recommended: SYSMAC CS/CJ series

Ethernet unit (Omron)

Connect to PLC to create an independent

low-energy system tailored to the

production environment.

Max./min./average values

Visual representation of particle volumes makes

it easier to identify trends for faster analysis!

Also handles time-consuming tasks such as

data storage and collation.

Shows hourly and daily trends at a glance-ideal

for early detection of problems.

Two display modes

Pop-up windows provide immediate notification of

alarms to enable a rapid response.

Select required log data and convert to CSV file

format. Direct import into Excel file format is also

available.