Laboratory Manual - Electrical & Computer Engineering

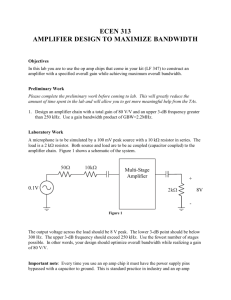

advertisement