ROBOLAB™ 2.5 Software Training Lab

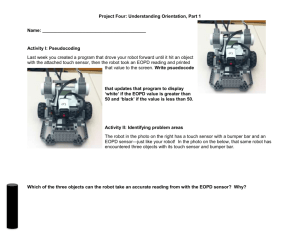

advertisement