Instruction Sheet

General Purpose pH/ORP Sensor Sensors

LIQ_MAN_ABR_3900

October 2014

General Purpose pH/ORP Sensor

Specifications

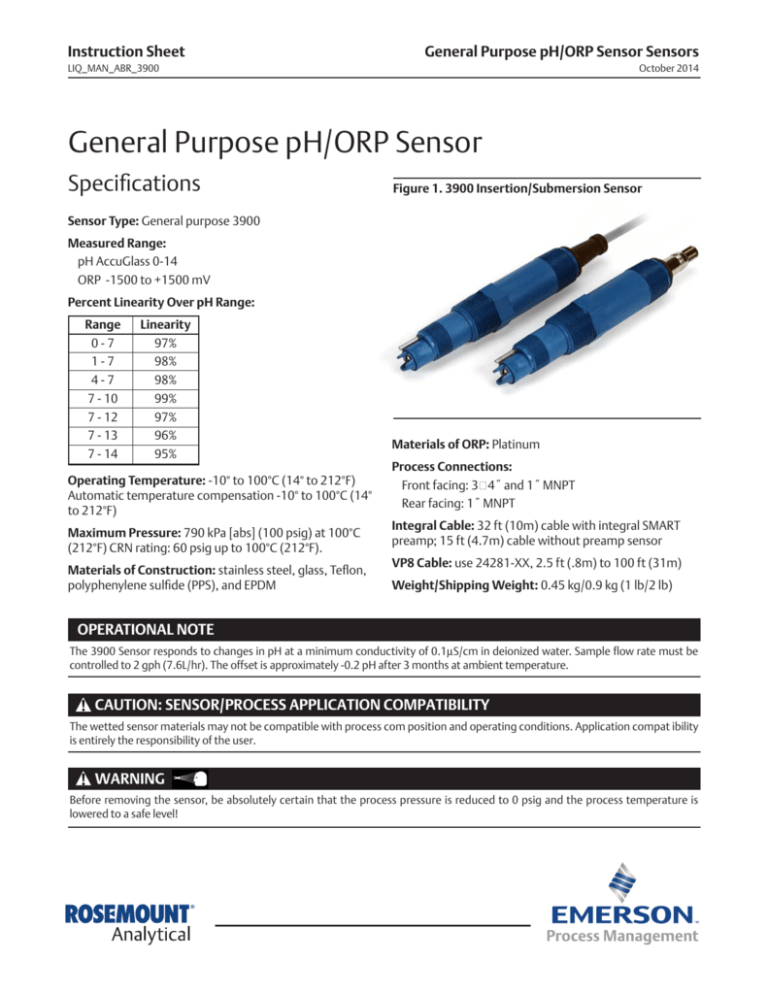

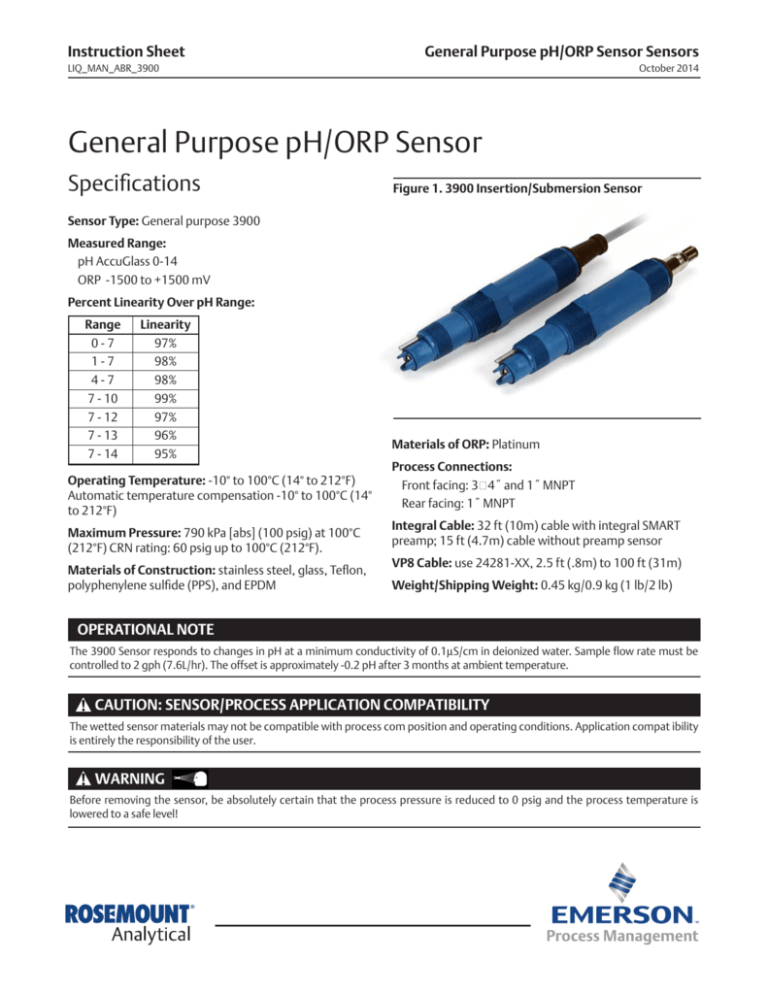

Figure 1. 3900 Insertion/Submersion Sensor

Sensor Type: General purpose 3900

Measured Range:

pH AccuGlass 0-14

ORP -1500 to +1500 mV

Percent Linearity Over pH Range:

RangeLinearity

0-7

97%

1-7

98%

4-7

98%

7 - 10 99%

7 - 12 97%

7 - 13

96%

7 - 14 95%

Operating Temperature: -10° to 100°C (14° to 212°F)

Automatic temperature compensation -10° to 100°C (14°

to 212°F)

Maximum Pressure: 790 kPa [abs] (100 psig) at 100°C

(212°F) CRN rating: 60 psig up to 100°C (212°F).

Materials of Construction: stainless steel, glass, Teflon,

polyphenylene sulfide (PPS), and EPDM

Materials of ORP: Platinum

Process Connections:

Front facing: 3⁄4˝ and 1˝ MNPT

Rear facing: 1˝ MNPT

Integral Cable: 32 ft (10m) cable with integral SMART

preamp; 15 ft (4.7m) cable without preamp sensor

VP8 Cable: use 24281-XX, 2.5 ft (.8m) to 100 ft (31m)

Weight/Shipping Weight: 0.45 kg/0.9 kg (1 lb/2 lb)

OPERATIONAL NOTE

The 3900 Sensor responds to changes in pH at a minimum conductivity of 0.1mS/cm in deionized water. Sample flow rate must be

controlled to 2 gph (7.6L/hr). The offset is approximately -0.2 pH after 3 months at ambient temperature.

CAUTION: SENSOR/PROCESS APPLICATION COMPATIBILITY

The wetted sensor materials may not be compatible with process com position and operating conditions. Application compat ibility

is entirely the responsibility of the user.

WARNING

Before removing the sensor, be absolutely certain that the process pressure is reduced to 0 psig and the process temperature is

lowered to a safe level!

General Purpose pH/ORP Sensor

Instruction Sheet

October 2014

LIQ_MAN_ABR_3900

CAUTION

The solution used during calibration is an acid and should be handled with care. Follow the directions of the acid manufacturer. Wear

the proper protective equipment. Do not let the solution come in contact with skin or clothing. If contact with skin is made, immediately rinse with clean water.

ATEX DIRECTIVE: Special Conditions for safe use

1. All pH/ORP sensors have a plastic enclosure which must only be cleaned with a damp cloth to avoid the danger due to a build up of

an electrostatic charge.

2. All pH/ORP sensor models are intended to be in contact with the process fluid and may not meet the 500V r.m.s. a.c. test to earth.

This must be taken into consideration at installation.

Storage

1. It is recommended that electrodes be stored in their

original shipping containers until needed.

2. Do not store at temperatures below -10°C (14°F).

3. Electrodes should be stored with a protective cap

containing KCl solution (PN 9210342).

4. For overnight storage, immerse the sensor in tap

water or 4 pH buffer solution.

5. pH glass electrodes slowly deteriorate in storage. There

is no specific expiration date. However, the calibration

procedure described below should be followed to

determine that the sensor calibrates properly.

Electrode preparation

1. Remove electrode from shipping container.

2. Remove the protective boot covering the electrode bulb.

3. Rinse away salt film with clean water, then shake the

electrode so that the internal solution fills the bulb,

thus removing any air trapped there.

Installation

For sensor orientation, see Figure 2.

For sensor dimensions, see Figure 3.

For mounting options, see Figures 4-7.

For wiring, see Figures 8-41.

For additional wiring information, please visit our website

at www.emersonprocess.com/raihome/liquid/wiring.

Wrap the sensor threads with six or seven (6–7) turns of

Teflon tape to prevent leakage. Do not over tighten the

sensor into it’s receptacle. Hand tighten the sensor, and

then tighten one or two (1–2) turns with a wrench.

Two point buffer calibration

Select two stable buffer solutions, preferably pH 4.0 2

and 10.0 (pH buffers other than pH 4.0 and pH 10.0 can be used as long as the pH values are at least two pH units apart).

NOTE: A pH 7 buffer solution reads a mV value of approx.

zero, and pH buffers read approximately ± 59.1 mV for

each pH unit above or below pH 7. Check the pH buffer

manufacturer specifications for millivolt values at various

temperatures since it may affect the actual value of the

buffer solution mV/pH value.

1. Immerse sensor in the first buffer solution. Allow

sensor to equilibrate to the buffer temperature (to

avoid errors due to temperature differences between

the buffer solution and sensor temperature) and wait

for reading to stabilize. Value of buffer can now be

acknowledged by analyzer/ transmitter.

2. Once the first buffer has been acknowledged by the

analyzer/transmitter, rinse the buffer solution off of

the sensor with distilled or deionized water.

3. Repeat steps 1 and 2 using the second buffer

solution.

4. The theoretical slope value, according to the Nernst

equation for calculating pH, is approximately 59.1

mV/pH. Over time the sensor will age, both in the

process and in storage, which will result in reduced

slope values. To ensure accurate readings, it is

recommended that the electrode be replaced when

the slope value falls below 47 to 49 mV/pH.

Recommended pH Sensor

Standardization

For maximum accuracy, the sensor can be standardized

on-line or with a process grab sample after a buffer

calibration has been performed and the sensor has been

conditioned to the process. Standardization accounts

for the sensor junction potential and other interferences.

Standardization will not change the sensor’s slope but

will simply adjust the analyzer’s reading to match that of

the known process pH.

Instruction Sheet

General Purpose pH/ORP Sensor Sensors

LIQ_MAN_ABR_3900

October 2014

Maintenance for pH electrode

Figure 2. Sensor Orientation

Electrodes should respond rapidly. Sluggishness, offsets,

and erratic readings are indicators that the electrodes

may need cleaning or replacement.

1. To remove oil deposit, clean the electrode with a mild

non-abrasive detergent.

2. To remove scale deposits, soak electrodes for 1 to 5

minutes in a 5% hydrochloric acid solution.

3. Temperature effect on life expectancy: If glass

electrode life expectancy is 100% at 25°C (77°F), then

it will be approximately 25% at 80°C (176°F), and

approximately 10% at 100°C (212°F).

CAUTION

Hydrochloric acid is toxic and highly corrosive. Avoid skin

contact, wear protective gloves. Use only in a well ventilated area. Do not inhale fumes. In case of an accident,

consult a doctor immediately.

ORP Calibration

1. After making an electrical connection between

the sensor and the instrument, obtain a standard

solution of saturated quinhydrone PN R508-8OZ

(475mV). This can also be made quite simply by

adding a few crystals of quinhydrone to either pH 4

or pH 7 buffer. Quinhydrone is only slightly soluble,

therefore only a few crystals will be required.

2. Immerse the sensor in the standard solution. Allow

1-2 minutes for the ORP sensor to stabilize.

3. Standardize the instrument to the solution value

shown in the table, right. The resulting potentials,

measured with a clean platinum electrode and

saturated KCl/AgCl reference electrode, should be

within +/- 20 millivolts of the value shown in the

table below. Solution temperature must be noted to

ensure accurate interpretation of results. The ORP

value of saturated quinhydrone solution is not stable

over long periods of time. Therefore, these standards

should be made up fresh each time they are used.

4. Remove the sensor from the buffer, rinse, and install

in the process.

Maintenance for ORP Electrode

Electrodes should respond rapidly. Sluggishness, offsets,

and erratic readings are indicators that the electrodes

may need cleaning or replacement.

1. To remove oil deposit, clean the electrode with a mild

non-abrasive detergent.

2. To remove scale deposits, soak electrodes for 1 to 5

minutes in a 5% hydrochloric acid solution.

3. ORP (metallic) electrodes should be polished with

moistened baking soda.

Figure 3. Sensor Dimensions

WRENCH FLATS

1.30 IN ACROSS

1 IN MNPT

3/4 IN MNPT

1 IN MNPT

TEMP COMP

SOLN GND

REFERENCE

JUNCTION

pH ELECTRODE

.92

2.33

6.91

8.63

3

General Purpose pH/ORP Sensor

Instruction Sheet

October 2014

LIQ_MAN_ABR_3900

Figure 3. Sensor Dimensions

WRENCH FLATS

1.30 IN ACROSS

1 IN MNPT

3/4 IN MNPT

1 IN MNPT

TEMP COMP

SOLN GND

REFERENCE

JUNCTION

pH ELECTRODE

.92

2.33

6.91

8.63

Figure 4. Typical Flow Through insertion installation using PN 2002011 Pipe Tee (sensor must be installed at

least 10° above the horizon)

Horizontal Pipe Tee (PN 2002011)

Pressure/Temperature Ratings

psig (kPa [abs])

150 (1136)

128 (984)

102 (805)

80 (653)

57 (494)

48 (432)

Figure 5. Low Flow Cell PN 24091-00

°F (°C)

150 (65)

160 (71)

170 (77)

180 (82)

200 (93)

210 (99)

INCH

MILLIMETER

Inlet and outlet connections are stainless steel and

take 1/4-inch OD tubing. Flow cell is polycarbonate

with 1/4-inch FNPT fittings.

Wetted materials:

Body & Nut – Polyester/Polycarbonate

Fittings – 316 SST

Seals – Silicone

Flow cell ratings:

Temperature: 32˚-158˚F (0-70˚C)

Max. Pressure: 90 PSIG (721 kPa [abs])

Flow rate: 2-5 GPH (7.6-18.9 LPH)

4

Instruction Sheet

General Purpose pH/ORP Sensor Sensors

LIQ_MAN_ABR_3900

October 2014

Figure 6. Jet Spray Cleaner PN 12707-00 (sensor must be installed at least 10° above the horizon)

The Jet Spray Cleaner eliminates routine,

manual sensor maintenance by cleaning the

sensor with water or compressed air. Flow

through the cleaner can be controlled by a

solenoid valve.

NOTE: The Jet Spray Cleaner can be used with

Handrail Mounting Assembly (PN 11275-01,

not shown) or can be mounted through

conduit as shown below.

Jet Spray Cleaner shown with

3900VP pH sensor

Figure 7. Low Flow Panel PN SQP10077-LQD

Low Flow Panel Specifications

Inlet flow 3-80 gph (11.4-304 L/hr)

Inlet pressure

3 – 65 psig (122 – 549 kPa abs)*

Temperature 32 - 122°F (0 - 50°C)

*The minimum inlet pressure is required to open a check valve, which prevents the flow cell from draining if sample flow is lost. Removing the check

valve lowers the inlet pressure requirement to a few feet of water head.

5

General Purpose pH/ORP Sensor

October 2014

Instruction Sheet

LIQ_MAN_ABR_3900

NOTE

For additional wiring information on this product, including sensor combinations not shown here, please refer to either our online wiring programs or

the Manual DVD enclosed with each product.

1056, 1057, 56, 5081, 6081, 54e, and XMT: http://www3.emersonprocess.com/raihome/sp/liquid/wiring/XMT/

1066 and sensors with SMART preamps: http://www2.emersonprocess.com/en-US/brands/rosemountanalytical/Liquid/Sensors/Pages/ Wiring_Diagram.aspx

1055: http://www3.emersonprocess.com/raihome/sp/liquid/wiring/1055

Figure 8. 3900-01 and 3900VP-01 to 54epH/ORP

Figure 9. 3900-02 and 3900VP-02 to 54epH/ORP

6

Instruction Sheet

LIQ_MAN_ABR_3900

General Purpose pH/ORP Sensor Sensors

October 2014

Figure 10. Sensor Wiring 3900VP-01 gray cable to 54epH/ORP

Figure 11. Sensor Wiring 3900VP-02 gray cable to 54epH/ORP

7

General Purpose pH/ORP Sensor

October 2014

Figure 12. 3900-01 and 3900VP-01 to Xmt

Figure 13. 3900-02 and 3900VP-02 to Xmt

8

Instruction Sheet

LIQ_MAN_ABR_3900

Instruction Sheet

LIQ_MAN_ABR_3900

General Purpose pH/ORP Sensor Sensors

October 2014

Figure 14. Sensor Wiring 3900VP-01 with gray cable to XMT

Figure 15. Sensor Wiring 3900VP-02 with gray cable to Xmt

9

General Purpose pH/ORP Sensor

October 2014

Figure 16. 3900-01 and 3900VP-01 to 1055

Figure 17. Two-Input 3900-01 and 3900VP-01 to 1055

10

Instruction Sheet

LIQ_MAN_ABR_3900

Instruction Sheet

LIQ_MAN_ABR_3900

General Purpose pH/ORP Sensor Sensors

October 2014

Figure 18. 3900-02 and 3900VP-02 to 1055

Figure 19. Two-Input 3900-02 and 3900VP-02 to 1055

11

General Purpose pH/ORP Sensor

October 2014

Instruction Sheet

LIQ_MAN_ABR_3900

Figure 20. Wiring with Remote Junction Box and Preamp (PN 23555-00) to 3900-02 and 3900VP-02

Figure 21. 1055pH/pH Wiring through Remote Junction Boxes to 3900-02 and 3900VP-02

12

Orange

Clear

Blue

Gray

White/Gray

Red

White/Red

White

Green

ID (inner drain)

(No Connection

TB 2

+5VDC / +V SNSR

-5VDC /-V SNSR

pH/pH in

pH SHLD / SHLD / GUARD

GND/SOL GND

REF / REF IN

Ref SHLD / SHLD /GUARD

RTD IN

RTD SENSE /SNS

RTD RTN /RTN

sensor or VP8 cable instead of using

shown wiring scheme.

Rosemount Analytical

intruments:

Extension Cable PN 9200348 can also 56 / 1056 / 1057 /

be used; extend color scheme from

1066 / 6081

Extension Cable PN 23646-01 or

9200273 shown

Green (+5 VDC)

Brown (-5VDC)

Black ( mV/pH in)

White/Black ( mV/pH Shield)

Blue (Solution Ground)

Gray (Reference in)

White/Gray (Reference Shield)

Red (RTD in)

White/Red (RTD Sense)

White (RTD Return)

ID (inner drain)

Remote Junction Box PN 23555-00 or Sensor Head Junction Box PN 23709-00

(Both J-boxes include Preamplifier Board PN 23557-00)

No Connection

BNC

11

11

TB 1

12

10

10

9

9

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

10

10

9

9

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

Connect to instrument

ground or as shown

3900 Sensors, Preamplifier in Junction Box

• For 3900-02 and 3900VP-02 sensors

• Non-preamp sensors

• Blue Cable

10

9

8

7

6

5

4

3

2

1

54epH/ORP XMT

5081

12

11

10

9

8

7

6

5

4

3

2

1

Instruction Sheet

LIQ_MAN_ABR_3900

General Purpose pH/ORP Sensor Sensors

October 2014

Figure 22. 3900 Sensors, Preamplifier in Junction Box

13

14

Orange

Clear

Blue

Gray

White/Gray

Red

White/Red

White

Green

ID (inner drain) (+5V)

White/Gray (-5V)

Orange ( mV/pH in)

Clear ( mV/pH Shield)

Blue (Solution Ground)

Gray (Reference in)

Red (RTD in)

White/Red (RTD Sense)

White (RTD Return)

Green

+5VDC / +V SNSR

-5VDC /-V SNSR

pH/pH in

pH SHLD / SHLD / GUARD

GND/SOL GND

REF / REF IN

Ref SHLD / SHLD /GUARD

RTD IN

RTD SENSE /SNS

RTD RTN /RTN

Rosemount Analytical

intruments: 56 / 1056 / 1057 /

1066 / 6081

Connect to instrument

ground or as shown

• For 3900-01 and 3900VP-01 sensors

• Preamplifier in sensor

• Blue Cable

3900 Sensors, Preamplifier in Sensor

10

XMT

54epH/ORP

5081

9

8

7

6

5

4

3

2

1

12

11

10

9

8

7

6

5

4

3

2

1

-01

October 2014

-70, 3400HTVP-70,

General Purpose pH/ORP Sensor

Instruction Sheet

LIQ_MAN_ABR_3900

Figure 23. 3900 Sensors, Preamplifier in Sensor

7

7

7

7

TB 1

12

11

10

10

9

9

TB 2

12

11

11

10

10

9

9

8

8

6

6

6

6

8

8

5

5

4

4

3

3

2

2

5

5

4

4

3

3

2

2

1

Remote Junction Box PN 23550-00 (with

Extension board for point-to-point wiring)

ID (inner drain)

White/Gray

Orange

Clear (Orange shield)

Blue

Gray

Red

White/Red

White

Green

1

+5VDC / +V SNSR

-5VDC /-V SNSR

pH/pH in

pH SHLD / SHLD / GUARD

GND/SOL GND

REF / REF IN

Ref SHLD / SHLD /GUARD

RTD IN

12

11

10

9

8

7

6

5

4

3

2

1

can also be used; White/gray

is replacement wire color for Brown wire.

54epH/ORP

Rosemount Analytical

5081

intruments: 56 / 1056 / 1057 /

Extension Cable PN 9200348

1066 / 6081

Extension Cable PN 23646-01

or 9200273 shown.

Green (+5 VDC)

Brown (-5VDC)

Black ( mV/pH in)

White/Black (mV/pH Sheild)

Blue (Solution Ground)

Gray (Reference in)

White/Gray (No connection)

Red (RTD in)

White/Red (RTD Sense)

RTD RTN /RTN

RTD SENSE /SNS

Connect to instrument

ground or as shown

White (RTD Return)

Inner Drain

• For 3900-01 and 3900VP-02 sensors

• Preamplifier in sensor

• Blue Cable

3900 Sensors, Preamplifier in Sensor,

Junction Box used for extending cable

XMT

10

9

8

7

6

5

4

3

2

1

Instruction Sheet

LIQ_MAN_ABR_3900

General Purpose pH/ORP Sensor Sensors

October 2014

Figure 23. 3900 Sensors, Preamplifier in Sensor

15

General Purpose pH/ORP Sensor

October 2014

Figure 22. 3900-01 and 3900VP-01 to Models 5081, 4081 or 3081

Figure 23. 3900-02 and 3900VP-02 to Models 5081, 4081 or 3081

16

Instruction Sheet

LIQ_MAN_ABR_3900

Instruction Sheet

General Purpose pH/ORP Sensor Sensors

LIQ_MAN_ABR_3900

October 2014

Figure 10. Wiring for 3900-01 and 3900VP-01 to 56, 1056 & 1057 pH

Figure 11. Wiring for 3900-02 and 3900VP-02 to 56, 1056 & 1057 pH

17

General Purpose pH/ORP Sensor

October 2014

Figure 26. Sensor Wiring 3900VP-01 with gray cable to 1056/56

Figure 27. Sensor Wiring 3900VP-02 with gray cable to 1056/56

18

Instruction Sheet

LIQ_MAN_ABR_3900

Instruction Sheet

LIQ_MAN_ABR_3900

General Purpose pH/ORP Sensor Sensors

October 2014

Figure 28. Sensor Wiring 3900VP-01 with gray cable to 1057

Figure 29. Sensor Wiring 3900VP-01 with gray cable to 1057

19

General Purpose pH/ORP Sensor

October 2014

Instruction Sheet

LIQ_MAN_ABR_3900

Figure 30. pH/ORP Sensor Wiring – 1066/3900VP-01 (blue cable – refer to manual for recommended cable order)

Figure 31. pH/ORP Sensor Wiring – 1066/3900VP-02 (gray cable – refer to manual for recommended cable order)

20

Instruction Sheet

General Purpose pH/ORP Sensor Sensors

LIQ_MAN_ABR_3900

October 2014

Figure 32. pH/ORP Sensor Wiring – 1066/3900VP-01 (refer to manual for recommended cable order)

Figure 33. pH/ORP Sensor Wiring – 1066/3900VP-01 (blue cable – refer to manual for recommended cable order)

21

General Purpose pH/ORP Sensor

October 2014

Instruction Sheet

LIQ_MAN_ABR_3900

Figure 34. pH/ORP Sensor Wiring – 1066/3900VP-02 (refer to manual for recommended cable order)

Figure 35. pH/ORP Sensor Wiring – 1066/3900VP-02 (blue cable – refer to manual for recommended cable order)

22

Instruction Sheet

LIQ_MAN_ABR_3900

General Purpose pH/ORP Sensor Sensors

October 2014

Figure 36. Sensor Wiring 3900VP-01 with gray cable to 5081

Figure 37. Sensor Wiring 3900VP-01 with gray cable to 5081

23

General Purpose pH/ORP Sensor

October 2014

Figure 38. 3900-01 and 3900VP-01 to 6081-P

Figure 39. 3900-02 and 3900VP-02 to 6081-P

24

Instruction Sheet

LIQ_MAN_ABR_3900

Instruction Sheet

LIQ_MAN_ABR_3900

General Purpose pH/ORP Sensor Sensors

October 2014

Figure 40. Sensor Wiring 3900VP-01 with gray cable to 6081

Figure 41. Sensor Wiring 3900VP-02 with gray cable to 5081

25

General Purpose pH/ORP Sensor

Instruction Sheet

October 2014

LIQ_MAN_ABR_3900

Ordering Information

The 3900/3900VP pH/ORP Sensor is housed in a PSS

plastic body with built-in solution ground for advanced

diagnostics. A Pt-100 RTD is offered for temperature

compensator. The sensor is available with an integral cable

or VP8 connector. Junction box kits with preamplifiers

can be ordered separately if an analyzer/ transmitter with

an integral preamplifier is not located within 15 ft. of the

sensor. SMART preamplifier (-01) is the standard preamplifier option, and is compatible with models XMT, 3081,

5081, 6081, 54e, 1055 and 1056 analyzers/transmitters.

3900 pH/ORP Sensor - New Generation general purpose sensor

Code

01

02

Code

10

12

Preamplifier Option

Preamplifier

No preamplifier

Measuring Electrode

General Purpose Low resistivity GPLR pH Glass (0 - 14pH)

Platinum ORP

EXAMPLE 3900 - 01 - 12

3900VP pH/ORP Sensor - New Generation general purpose sensor with VP

Code

01

02

Code

10

12

Preamplifier Option

Preamplifier

No preamplifier

Measuring Electrode

General Purpose Low resistivity GPLR pH Glass (0 - 14pH)

Platinum ORP

EXAMPLE 3900VP - 02 - 10

26

Instruction Sheet

General Purpose pH/ORP Sensor Sensors

LIQ_MAN_ABR_3900

October 2014

Accessories

Part Number

Description

24281-00

15 ft. cable with mating VP8 connector

24281-01

25 ft. cable with mating VP8 connector

24281-02

2.5 ft. cable with mating VP8 connector

24281-03

50 ft. cable with mating VP8 connector

24281-04

100 ft. cable with mating VP8 connector

24281-05

4 ft. cable with mating VP8 connector

24281-06

10 ft. cable with mating VP8 connector

24281-07

20 ft. cable with mating VP8 connector

24281-08

30 ft. cable with mating VP8 connector

12707-00

Jet cleaner

23242-02

Insertion adapter

24091-00

Low flow cell

23555-00

Junction Box with Preamplifier for Models 54e, 3081, 4081, 5081, XMT, 1055, 1056

2002011

CPVC flow through Tee, 1-1/2 in. NPT process connection

11275-01

Sensor handrail assembly

9210012

Buffer solution, 4.01 pH, 16oz

9210013

Buffer solution, 6.86 pH, 16oz

9210014

Buffer solution, 9.18 pH, 16oz

9200273

Extension cable, gray

9200348

Extension cable, blue

SQP10077-LQD

Low Flow Control Panel

27

LIQ_MAN_ABR_3900

Rev. E

October 2014

facebook.com/EmersonRosemountAnalytical

8

Credit Cards for U.S. Purchases Only.

AnalyticExpert.com

twitter.com/RAIhome

youtube.com/user/RosemountAnalytical

Emerson Process Management

©2014 Rosemount Analytical, Inc. All rights reserved.

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

The Emerson logo is a trademark and service mark of Emerson Electric Co. Brand name is a mark of one

of the Emerson Process Management family of companies. All other marks are the property of their

respective owners.

RosemountAnalytical.com

The contents of this publication are presented for information purposes only, and while effort has been

made to ensure their accuracy, they are not to be construed as warranties or guarantees, express or

implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available on request. We reserve the right to modify or

improve the designs or specifications of our products at any time without notice.