RT-SDR-M01 B - RedBookLive

advertisement

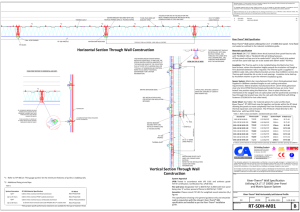

DIRECTION OF LAY BRACKET 150mm FROM PLAIN END OF MATRIX BAR MATRIX BAR MSB-3500 (3500mm LONG) 500 500 REVISIONS: RT-BLOCK RT-500 PROFILE 150 2No. SC32 FIXINGS *2 *2 MAX 1167mm MAX 1167mm *2 MAX 1167mm MAX 1167mm THERMA-QUILT INSULATION CA 32 1000RL 0.7mm THICK NOMINAL LINER PANEL T-FOIL PLUS SIDE LAP SEALANT TSC20G19 FOR CRS OR TSL36G19 FOR HRS NOTE: FIXINGS SHOULD BE INSTALLED IN ALL CORRUGATIONS AT EAVES AND HIP MATRIX BRACKET SECURED WITH 2No M27G16 FIXINGS (CRS) or TSL36G16 (HRS) 1000 COVER 1000 COVER 1000 COVER Section Through Roof Construction VERGE FASCIA TO MATCH WALL CLADDING MATERIAL, REFER TO DETAIL DRAWING FOR FIXING INFORMATION BAR & BRACKET CONNECTED WITH M27G16 FIXING RT-BLOCK RT-500 PROFILE BRACKET DEPTH T-STRIP 6x5 *2 TYPICAL 420mm / MAX 600mm SPACING TYPICAL 500mm / MAX 600mm SPACING 1000 mm SPACING / MAX 1167mm SPACING CA 32 1000RL 0.7mm THICK NOMINAL LINER PANEL Materials specification Liner Panel: CA 32 1000RL 0.7mm thick (nominal) liner panel fixed to purlins with TSC20G19 CRS or TSL36G19 HRS self-drilling fasteners. All liner panel end laps are to be sealed with T-strip 6x5 butyl strip sealant and all liner panel side laps are to be sealed with 50mm wide T-foil Plus. The liner panel will self curve to 45m convex radius. METAL Insulation: The Therma-quilt is to be installed below the Matrix bar from eaves to ridge, where the slope length exceeds the insulation roll length a firm abutment between rolls is required. The Therma-quilt is supplied in 1200mm wide rolls, where Matrix brackets are less than 1200mm centres the Therma-quilt should be slit on site to suit spacings. 60 CL of TSC20G19 fixin *1 - PURLIN g LINER PANEL POSITIONED TO SUIT PROJECT REQUIREMENTS (SITE CUT IF REQUIRED) THERMA-FOIL PLUS AND AIR SEALED WITH T-FOIL PLUS 80 SIDE LAP SEALANT MATRIX BRACKET SECURED WITH 2No M27G16 FIXINGS (CRS) or TSL36G16 (HRS) CLEADER ANGLE SUPPLIED & FITTED BY STEELWORK CONTRACTOR 30 30 METAL PTH O/A SYSTEM DE SEE TABLE 2 2No. SC32 FIXINGS TYPICAL 260mm / MAX 280mm *1 - PURLIN 43 15 KNEE BRACE FIXED WITH 4No M27G16 FIXINGS SEE TABLE 2 FOR REQUIREMENTS 80mm WIDE T-FOIL PLUS AIR SEAL roof system utilising the CA 32 1000RL liner panel. Once fully fixed and sealed as outlined in the installation guide RG-M-04 the final construction is a Class B Non-Fragile assembly in accordance with the HSE materials standard ACR(M)001:2005 'Test for Non-Fragility of Profiled Sheeted Roofing Assemblies ( third edition )'. MATRIX BAR MSB-3500 (3500mm LONG) Start and End of Bar and Bracket Requirements Spacer System: Matrix bar manufactured from 1.5mm thick galvanised steel. Supplied in 3000mm or 3500mm standard lengths. Matrix bracket manufactured from 1.6mm thick galvanised steel c/w 3mm EPDM thermal break pad bonded to base are to be 'twist locked' into position along the Matrix bar. Once in place the bars are interlocked at the swaged end and the positioned assembly is fixed through the bracket base into the purlins with 2No M27G16 self drilling fasteners (TSL36G16 for hot rolled steel). Metal over Metal Endlap System Appraisal Non-Fragility: Refer to TIP-101 for Non-Fragility tolerances LPCB: Tested in accordance with LPS 1181 and achieves grade 'EXT-B' certification. Certification No. LPCB 443a Fire roof area: Designated 'AA' to BS476:Part 3:2004 with liner panel being class '0' surface spread of flame to BS476:Part 7:1997 The River-Therm system can be supplied with inplane or barrel vault rooflights refer to the following drawings for more information: RT-SDR-M02 - 1 metre wide barrel vault rooflight. RT-SDR-M03 - 2 metre wide barrel vault rooflight. Outer Sheet: See Table 1 for material options and curving parameters for outer profile sheet. RT-500 Panel snap-fix together and locate within the RT-block allowing the panels to move completely free from frictional attrition during thermal expansion and contraction. The RT-block is fixed directly to the Matrix bar with two SC32 RT-Fixing. CA Building Products Evenwood Industrial Estate Copeland Road, Evenwood Co. Durham. DL14 9SF BBA: Independant verification of all aspects of the system refer to certificate 07/4428 for full information Acoustics: Please consult TIP-401 for weighted sound reduction (Rw) figures METAL GUTTER MANUFACTURERS ASSOCIATION T: 01388 834242 F: 01388 834711 E: technical@cagroup.ltd.uk W: www.cagroup.ltd.uk THE METAL CLADDING & ROOFING MANUFACTURERS ASSOCIATION THE NATIONAL FEDERATION OF ROOFING CONTRACTORS LIMITED BS I EN 14782:2006 TM ISO 9001 FS 10446 Table 2 - Roof U-values and depths - standard build-ups in bold This specification drawing is for general guidance only and should be read in conjunction with the relevant NBS specification and *1 - Refer to TIP-406 on 'Thin gauge purlins' for the minimum thickness of purlins / cladding rails *2 - Additional fixing at liner end laps & apex (4No total) Table 1 System Guarantee N/A* Up to 25 Years N/A* Up to 40 Years Bracket Ref Therma-quilt MSS-80 TQ100 MSS-100 TQ120 158mm n/a MSS-120 TQ140 178mm n/a MSS-140 TQ160 198mm n/a MSS-160 TQ180 218mm n/a MSS-180 TQ200 238mm MKB-180 U-Value System Depth Knee Brace n/a 138mm Convex Min. Self curve radius 30 metres Convex Min. Mechanically smooth curve radius 5 metres MSS-200 TQ220 258mm MKB-200 RT-Block Black Polyamide MSS-220 TQ240 278mm MKB-220 MSS-240 TQ260 298mm MKB-240 0.8mm thick nominal PVDF coated aluminium 30 metres 5 metres Black Polyamide MSS-260 TQ280 318mm MKB-260 0.8mm thick nominal stucco embossed aluminium 30 metres 5 metres White Poliossimetilene MSS-280 TQ300 338mm MKB-280 0.55mm thick nominal Colorcoat HPS200 Ultra coated steel 30 metres 6 metres Black Polyamide MSS-300 2x TQ160 358mm MKB-300 RT-500 Material Specification 0.8mm thick nominal mill finish aluminium *Only project specific performance statements are available for this type of material / finish. U-values quoted based on average bracket spacings of 1000mm and bar spacing of 1400mm TITLE: Utilising CA 32 1000RL Liner Panel and Matrix Spacer System SYSTEM: DRAWN: CHECKED: EH DRAWING No: DATE: LD/SB 20 APRIL 2011 RT-SDR-M01 SCALE: 1:10 @ A3 REV: B