Systems Engineering Revitalization and Sustainment

advertisement

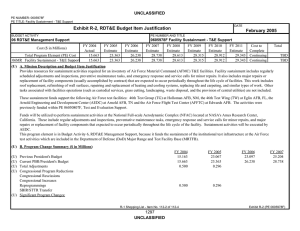

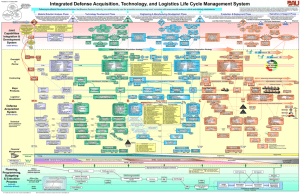

Systems Engineering Revitalization and Sustainment presented to: 2006 DoD Maintenance Symposium & Exhibition 25 Oct 06 Bob Skalamera Deputy Director, Systems and Software Engineering (Enterprise Development) Office of the Deputy Under Secretary of Defense (A&T) SE Revitalization: Links to Sustainment ¾ Current SE Policy requires a SEP at MS C ¾ Defense Acquisition Guidebook – Chapter 4 on SE • Section 4.3.5 – Operations and Support Phase • Section 4.4 – Design Considerations • Calls for a dedicated technical review (In-Service Review) in O&S ¾ SEP Prep Guide – technical planning focus areas include aspects for post-MS C and with emphasis on Sustainment ¾ Integrated Defense Acquisition, Technology, & Logistics Life Cycle Management Framework – “the Wall Chart” ¾ DAU’s Systems Planning, Research, Development, and Evaluation (SPRDE) courseware refocused on life cycle (SYS-202 and SYS203) ¾ Program Support Reviews – ongoing, active logistics participation http://www.acq.osd.mil/se/ Sustainment in Design Reviews Across the Life Cycle Sustainment in the design and throughout program execution Operations and Support Phase: Links to Sustainment Product Support/ PBL Management Operations & Sustainment INPUTS OUTPUTS •Service Use Data •User Feedback •Failure Reports •Discrepancy Reports •SEP •Input to CDD for next increment •Modifications/upgrades to fielded systems •SEP In-Service Review Monitor and Collect All Service Use Data Implement and Field Trades Analyze Analyze Data to Determine Root Cause Assess Risk of Improved System Determine System Risk/ Hazard Severity Integrate & Test Corrective Action Develop Corrective Action • Process Change – Hardware/Support • Materiel Change Program Support Reviews: Representative Reliability Issues ¾ Reliability Growth Program • Underestimating difficulty and resources to achieve and sustain reliability growth • Lack of proper planning, managing, and executing reliability growth activities • Program test design incompatible with reliability growth program aspects • Reliability growth program not funded throughout • Failure to consider correct use conditions/environment for reliability test ¾ Reliability Program • In some programs, failure to design in reliability up front • Inadequate quality and timeliness of root cause analysis and corrective actions ¾ DT vs. OT • OT evaluators using differing interpretations of failure or system use vs. early buy-in and agreement on the artifacts that illuminate the requirement (e.g., Operational Mode Summary/ Mission Profile and Failure Definition and Scoring Criteria) • Immaturity of scoring conference and process prior to use The Sustainment Challenge ¾ Our joint challenge is to make Sustainment: • Part of the upfront planning and review process through participation in Integrated Product Teams • Part of the event-based technical reviews • Part of design trades but not traded away during development • Part of the acquisition phase entrance and exit criteria ¾ Training and Guidance Resources • CLL 008 – Design for Supportability • CLE 003 – Technical Reviews • CLE 017 – Technical Planning • Guides: RAM, SEP, Risk Management, DAG Chapters 4 & 5 www.dau.mil/basedocs/trainingcourses.asp Back-up Approved Sustainment KPP and Mandatory KSAs ¾ Single KPP: • Materiel Availability: measures percentage of the entire population capable of performing an identified mission Requires both system design and sustainment approach to be addressed: Reliability, Maintainability, Service Life, Sustainment Strategy, Preventative Maintenance, Diagnostics, Supply Chain, Distribution, Transportation ¾ Mandatory KSAs: • Materiel Reliability: measures confidence an operational, ready end item will successfully complete its mission without a critical failure when tasked • Ownership Cost: measures what it costs to sustain a system after it is placed in service ¾ Goals: • Correct number of operational end items capable of performing the mission when needed • Confidence systems will perform the mission and return home safely without failure • Cost balance: solutions cannot result in availability and reliability “at any cost” Systems Engineering Plan Timing Reflects Program Acquisition Strategy Capability Needs Capabilities Sought AS R Pr Mg g m m S Bu t A truc s S pp tur tra roa e teg ch y Must be Consistent SE P RFP RFP Source Selection W S O es / O us ia SO Cla iter H Cr SS Shapes Contractor’s Execution Sets Contractor’s Technical Approach Technical Approach Reflects Program Technical Strategy Update SEP to negotiated contractor’s technical approach Design for supportability needs to be part of the technical plan, upfront and early SE Revitalization Overview ¾ Issued Department-wide Systems Engineering (SE) policy ¾ Issued guidance on SE, T&E, and SE Plans (SEPs) ¾ Instituted system-level assessments in support of DAB, OIPT, DAES, and ad hoc reviews ¾ Established SE Forum to ensure senior-level focus within DoD ¾ Integrating DT&E with SE policy and assessment functions--focused on effective, early engagement of both ¾ Instituting a renewed emphasis on modeling and simulation in acquisition ¾ Working with Defense Acquisition University to revise curricula (SPRDE, T&E, PQM, LOG, PM, ACQ, FM, CONT) ¾ Leveraging close working relationships with industry and academia Reliability Trends 1985-1990 8000 met 1000 900 41% Met Requirements 800 700 59% Not Met 600 500 FOTE 400 OT II 300 IOTE 200 User Test 100 DT/OT 0 0 200 400 600 Requirement MTB_ 800 1000 1200 1400 Reliability Trends 1996-2000 2500 1000 900 20% Met Requirements 800 700 80% Not Met 600 500 FIELD 400 LUT 300 FOT 200 IOT 100 DT/OT 0 0 200 400 600 800 Requirement MTB_ 1000 1200 1400 Model for Achieving RAM ¾ Understand and document the User needs and constraints ¾ Design and redesign for RAM ¾ Produce reliable, maintainable products ¾ Monitor field performance Operations and Support Inputs Outputs Service Use Data Data for In-Service Review User Feedback Input to CDD for next increment Failure Reports Modifications/upgrades to fielded systems Discrepancy Reports SEP SEP Reliability Bright Spots ¾ Good RAM requirements ¾ Reliability Management Board, with representation from PMO, user representative, operational tester, and prime contractor ¾ Unity of purpose regarding reliability between PMO and Prime Contractor ¾ Genuine pursuit of reliability by management of PMO, Prime and Subcontractors ¾ Using experienced reliability staff in PMO and Prime ¾ Well planned approach to RAM ¾ FMECA undertaken in design phase in a timely manner by design team to identify and remove failure modes from design concepts ¾ Failure database for failures in DT and OT ¾ A well funded and supported reliability growth program with active identification and removal of failure modes ¾ Use of advanced reliability growth models ¾ Dedicated reliability data collectors ¾ Provision of early operational testing ¾ Addressing false alarm rate with multifunctional team in DT ¾ DT and OT periods commensurate with RAM demonstration requirements Program Support Reviews Representative Reliability Issues ¾ Poor Requirements in ORD/CDD • Arbitrary values for Reliability Availability Maintainability (RAM) requirements • In some programs, failure to identify mission context or intended use profile, etc. • Failure to identify when reliability values are required (reliability and availability maturation points) • Failure to model to ensure harmony between reliability, availability, maintainability, and supportability characteristics • Failure to appreciate stochastic character of RAM and hence suitably consider statistical confidence issues