Monitoring Based Commissioning at UC Berkeley

advertisement

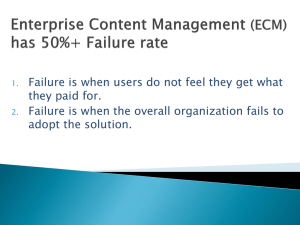

Monitoring Based Commissioning at UC Berkeley W. Mark Arney, PE Senior Engineer Facility Dynamics Engineering Optional: Insert Company Logo AIA Quality Assurance The Building Commissioning Association is a Registered Provider with The American Institute of Architects Continuing Education Systems (AIA/CES). Credit(s) earned on completion of this program will be reported to AIA/CES for AIA members. Certificates of Completion for both AIA members and non-AIA members are available upon request. This program is registered with AIA/CES for continuing professional education. As such, it does not include content that may be deemed or construed to be an approval or endorsement by the AIA of any material of construction or any method or manner of handling, using, distributing, or dealing in any material or product. Questions related to specific materials, methods, and services will be addressed at the conclusion of this presentation. Course Description This course covers the Monitoring-Based Commissioning program developed for the major state-owned universities in California . The primary focus is on the implementation of the program at the University of California at Berkeley. Learning Objectives At the end of this session, participants will be able to: 1. Participants will be able to describe the importance of submetering in a large campus environment. 2. Participants will understand the key components of the Monitoring Based Commissioning (MBCx) program in California. Co-Authors Patrick MacArdle, PE • Program Manager at UC Berkeley David Sellers, PE • Senior Engineer at FDE UC/CSU/IOU Energy Efficiency Partnership Overview • Implements energy efficiency strategies at 33 University of California and California State University campuses served by California’s 4 large investor owned utilities. • Established in 2004. Renewed and expanded in 2006 and 2009. Currently in 2009-2012 program cycle. • Strategies - Energy Efficiency Retrofits Monitoring Based Commissioning (MBCx) Emerging Technology Demonstrations Training and Education • Projects funded by combination of financing and incentives. Incentive amount based on proven energy saved by project as verified by investor owned utility MBCx in the Energy Efficiency Partnership ----compared to one-time Retro-Commissioning • Permanent electrical and thermal metering equipment required. • Education and training component to sustain savings. • Identify new energy efficiency retrofit opportunities. Monitoring Based Commissioning at UC Berkeley • All non-residential buildings over 50,000 square feet • Permanent electrical and steam/condensate meters • 21 buildings to date completed in 2009-2012 program cycle • 29 underway to be completed this year • Major undertaking was installing 33 meters in about a year Results for 17 completed buildings Total spent Incentives Net cost Annual avoided energy costs electrical rebate $2,400k $1,100k $1,300k $600k gas rebate $0.24/kWh saved $1.0/therm saved annually electrical cost gas cost $0.106/kWh $0.74/therm Additional References for MBCx Karl Brown (CIEE) ○ NCBC 2008 Mike Anderson (NAM) ○ NCBC 2007 Karl Brown (CIEE) ○ ACEEE 2006 MBCx Process Developed at UCB Strategic Energy Plan • Completed by NAM in 2008 ○ Covered more programs than MBCx ○ Initial building surveys ○ Building budgets developed based on type and size ○ Estimated savings of 7% Buildings Identified by UCB • Ones with high EUI were done first • Whole-building metering Installed • Consultants selected and assigned MBCx Process Developed at UCB (cont.) Phase 1: Initial Assessments and Reporting • Gather existing documentation • Meet w/ bldg managers and operations staff • Initial building walkthrough ○ “follow your nose” • Initial ECM identification (RCx measures) • Plans for more detailed investigation • Develop Baseline Energy Report and submit program forms ○ Look for weather dependency, occupancy patterns, etc. MBCx Process Developed at UCB (cont.) Phase 2: ECM Development and Implementation • Review ECMs with project team ○ Measures vary from simple and cheap to complex (see following slide) • Complete development of targeted ECMs ○ Heavy use of trend data w/ some portable loggers ○ Some require engineering design ○ Some earmarked for future installation under Retrofit program • Develop bid documents • Install & Commission Measures • Final Report All tasks must be completed in 1 year Typical Measures • Scheduling ○ Get existing AHU schedules from BAS operators ○ Look for manual overrides at HOAs ○ Work with bldg manager on new schedules ○ Occupant overrides installed if justified ○ Zone level for DDC terminal boxes • VFD replacements ○ Many failed and were not replaced ○ When in bypass or manual mode, BAS schedule is worthless ○ Replacement justified with energy and efficiency savings - Program does not pay for equipment replacements Typical Measures (cont.) • Variable speed pumping ○ Done on systems where conversion from constant to variable speed is relatively simple • Economizer repairs – ○ damper blades, linkages, actuators, control sequences ○ Coastal climate requires maintenance • Pump impeller trims (pumps often throttled > 50%) • Lighting Controls ○ Lighting eqpt ECM done through other programs ○ Tighten scheduling on existing systems ○ Reconnect abandoned systems • Focus on overlap of deferred maintenance & cx Limitations on Measures • Lack of Maintenance Resources ○ Don’t want new measures that add maintenance hours • Relative Low Energy Costs ○ 10 cents/kWh • Mild Climate ○ No extreme heating or cooling loads ○ Many buildings don’t have AC • Positive note: tons of trend data available! Case Study #1 – Le Conte Hall • UC Berkeley Physics Department home • 148,000 square feet • Four floors plus basement ○ Floors 1 and 2 - Classrooms and research ○ Floors 3 and 4 – Offices, class rooms, informal meeting space • Received “Best Practices” award in 2009 • 32% electrical savings • 15% thermal savings Targets - 7 of 17 ECMs Selected Thinking Outside the Box Click to editpump copy • Log condensate cycles text styles – 1 cycle = known volume • First levelSteam bullets – See Assessing Consumption with an Alarm ○ Second level Clock bullets at http://av8rdas.wordpress.com - Third level bullets for technique » Fourth level – Cross checkbullets with control system trend data Guideline for images: Please add 1 pt. green (R119G152B35) rule around each image The History of our Project from the Day the Meter Started Up Through Yesterday Savings Baseline shift Original baseline New Baseline Variable axis scale • The bottom is not always zero • The bottom value varies from screen to screen Our Award Winners Biggest Bang for the Buck Award Finding 06 – Schedule AHU2 Biggest Bang for the Buck Award Most of the energy savings can be attributed to this one finding • Easy to assess • Easy to implement • Obvius (cue laughter) signature at the meter Our Award Winners Most Ripple Effects Award Filter Operating Cost Components First cost component • Decreases over time • Non-linear Cost per Day Filter Operating Cost Increasing Time ○ Day 1 – Cost per day = Cost of filter set ○ Day X – Cost per day = (Cost of filter set)/X Days Energy cost component • Increases over time • Non-linear Total cost component • Decreases then increases over time • Change filters at inflection point for best life cycle cost Findings 03 and 04 – Filter Upgrades Most Ripple Effects Award Ripple Effects • Fewer resources to purchase • Smaller waste stream • Less labor spent on filters “State of the art” technology allows real time monitoring for the “inflection point” in the filter life cycle cost curve (a.k.a. the point in time when you should change the filters) ECMs (Energy Conservation Measures) The Fun Continues ECM 01 - AHU2 CHW Valve Optimization ECM 02 - CHW System Flywheel ECM 03 - AHU1 Scheduling ECM 04 - Zone Optimization ECM 05 - Condenser Heat Recovery ECM 06 - 208v System Optimization ECM 07 – Automated Diagnostics Case Study #2 – Davis Hall • 126,000 ft2 • Contains Labs and Offices for Civil Engineering Department • Received “Best Practices” award in 2011 Guideline for images: Please add 1 pt. green (R119G152B35) rule around each image Project Economics Summary 544,000 kWh (33% savings) 83,000 therms (77% savings) $168,300 annual savings Total potential rebate = $219,000 (but capped at 80% of project cost) Actual rebate = $175,000 Project cost = $195,000 •Includes consultant fees, in-house management & labor, and installation costs. Payback = 1.1 years (w/o rebate) Payback = < 2 months (w/ rebate) A Picture (or plot) is Worth… Measures Implemented • AHU Scheduling ○ Worked with bldg manager on new schedules • VFD replacements ○ Many failed and were not replaced ○ When in bypass or manual mode, BAS schedule is worthless – use trend data to identify • Lighting Controls ○ Load reduce by 60% ○ Some daylighting available (but not used for control) ○ Main open lab space is used sporadically ○ Enabled existing control system for night & weekends Measures Implemented (cont.) • Cooling / Heating system lockouts ○ None existed • Control SF-36 based on Temperature ○ 15 hp motor serving XFMR room ran 24/7 ○ Now only comes on when space temp > 80°F • Modify Hot Water Reset Schedule ○ Lowered high limit • Supply air reset ○ None existed ○ New sequences uses exhaust air temp as reference Case Study #3 – Haas School of Business • 126,000 ft2 • Offices, classrooms, library • Measures: replace VFDs, repair dampers, schedule AHUs and lighting • Savings looked great until… Guideline for images: Please add 1 pt. green (R119G152B35) rule around each image The Tale of Two Chillers Problem Identified and corrected Lesson Learned Keep an eye on the meter Guideline for images: Please add 1 pt. green (R119G152B35) rule around each image marka@facilitydynamics.com Presenter’s contact information and/or with Company Logo