Multivariable Prediction Based Controller Design for Important

advertisement

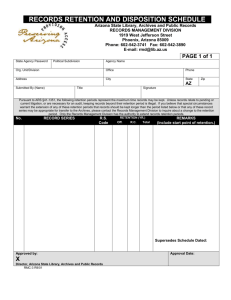

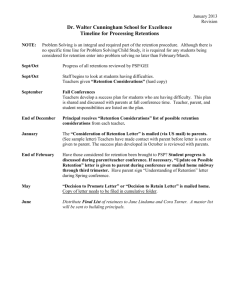

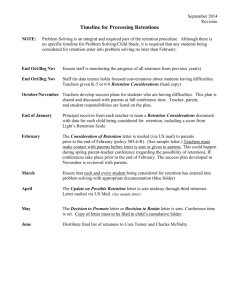

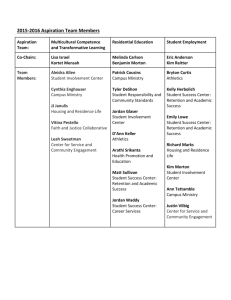

J OURNAL OF FOREST PRODUCTS & INDUSTRIES, 2014, 3(3), 158-160 ISSN: 2325–4513( PRINT) ISSN 2325 - 453X (ONLINE ) Research Article 158 Multivariable Prediction Based Controller Design for Important Controlled Variables of Wet End of Paper Machine 1 1 Pradeep Kumar Juneja , 2A. K. Ray* School of Electronics, Graphic Era University, Dehradun, India e-mail: pkj33dpt@iitr.ernet.in 2 Department of Paper Technology , IIT Roorkee, (Received: March 23, 2014; Accepted: May 18, 2014) Abstract— The implementation of retention control in the wet end is important because of requirement of higher paper quality with decreased basis weights. Multivariable control system with these two controlled variables is considered in present case. As experimental data on dynamics for this process is not available on industrial scale, known dynamics is considered for analysis. Controller for multivariable subsystem with retention and basis weight in wet end paper machine as controlled variables have been designed in the present work using Model Predictive Control strategy. Controller is tested for its setpoint tracking, disturbance rejection and robustness capabilities. Robustness issues are investigated for the subsystem by evaluating the performance after making perturbations in the original system. The response exhibit excellent set point tracking and acceptable disturbance rejection. Also there is not much adverse effect on the performance because of model uncertainty and hence the controller is robust. Index Terms — Controller, MPC multivariable transfer function model strategy, prediction, I. INTRODUCTION R etention is a critical parameter used for quality development for many industries. It is extremely important for fiber processing industries like paper, textiles, polymer, rubber, dye, pigment, asbestos etc., many metallurgical industries in connection with filtration and separation of fillers and fibers and waste water treatment for color and COD retention by nanofiltration membranes, for desalination, and inorganic and organic chemical industries. In paper industry this parameter is of paramount importance for paper quality development by better formation of fibrous mat on wet end wire. It is an important factor in wet end control of a paper machine. As per definition, retention of a material is the fraction of that material fed to the machine through the head box slice that is retained in the paper sheet. Definitions of retention depend on the specific types of materials retained on wire such as total solids, filler, fines, retention aids, chemicals, sizing particles, interfering substances and fibers. This is further defined based on either overall retention, first pass retention, first pass total solids retention or total solids retention, considering paper located at pope reel at the dry end of the entire machine or paper *Corresponding author e-mail: akrayfpt@iitr.ernet.in web leaving the couch roll at the end of wet end formation stage. Retention is affected by many variables like retention aids, stock pH values, stock flow rate, shear forces, pulp quality, head box slice geometry, raw material contaminants, drainage, machine speed and structure of white water system etc [1]. As the thick stock consistency, percent retention and white water consistency are all interlinked; the variability of retention strongly depends on variations in qualities of the thick stock and recycled white water consistency [2]. The advanced consistency measurement methods used in retention applications rely on a combination of optical measurement principles including depolarization, absorption and scattering [3]. To reduce variability of the output variables in the paper machine, the physical properties of thick stock should be constant. Fluctuations of the consistency, the fines content and the dissolved solids generally cause variations in the first pass retention and basis weight [4]. Rooke and Wang applied semi-physical method i.e. combined neural network and physical model to the retention process in papermaking. The retention included fines, fillers and fibers on the papermaking wire [5]. Retention of individual components is close to constant over a reasonable operating regime. The observed variation in total retention was due to variations in the fines content and to a smaller degree, variations in the fines retention [6]. The First Pass Retention monitoring and control is a vital part of the paper machine control. It gives a practical indication of the efficiency by which fine materials are retained in a web of paper as it is being formed. It should have a steady value, and that value should be high enough to avoid operational problems or an excessively two-sided sheet. Some operational problems that can be caused by its low values are increased frequency of deposit problems, filling of wet-press felts, poor drainage, and unsteady drainage rates and sheet moisture. It is very important to control the white water consistency and thus also the retention levels on paper machines. There are many economic benefits derived from white water consistency control including stabilization of paper machine operation. Besides there are some other potential advantages, which includes, improved operational stability and runnability of paper machines, increased production of saleable paper, less variation in white water, headbox ash consistencies, basis weight, moisture and thickness, enhanced final product quality, 159 J OURNAL OF FOREST PRODUCTS & INDUSTRIES, 2014, 3(3), 158-160 ISSN:2325–4513( PRINT) ISSN 2325 - 453X (ONLINE ) accurate retention aid dosage and better control and understanding of the wet end dynamics. In present analysis, MPC based controller is designed and robustness issues are investigated for this subsystem by evaluating the performance after making perturbations in the original system. II. MULTIVARIALE FUNCTION PROCESS TRANSFER Due to constant variations of all of the input variables during paper production and the involvement of fluid dynamics during the formation phase on the wire section, the system is dynamic, nonlinear and stochastic. An added complexity is that the retention is coupled strongly with other chemical systems in the wet end, such as sizing and wet strength control systems. This means that an accurate physical model of the retention process is very difficult to obtain and as a result, model based feedback control of retention has remained an unsolved problem. Orccotoma et al [7] investigated the effect of disturbances on the two output variables of paper machine with twin wire formers, viz, basis weight and first pass retention by using the concept of controllability. Time delays and high frequency disturbances of the thick stock consistency were shown to affect the process. First-pass retention is considered an uncontrolled variable and found to be dependent on fines content of the thick stock. Nonlinear processes such as, basis weight and first pass retention can well be represented by linear models. Non-linearity did not pose any significant error. Figure 1: Plant outputs for Servo Response for Unit Step in fpr set-point showing peak time and peak amplitude IV. ROBUSTNESS ANALYSIS The selected linearized multivariable process transfer function model of the paper machine forming section is perturbed by increasing all the values by 20% and the controleer designed based on MPC strategy is analyzed for its setpoint tracking and disturbance rejection capability. III. MPC BASED CONTROLLER DESIGN The controller for the selected subsystem is designed for analyzing its set-point tracking, disturbance rejection and robustness capability based on MPC strategy. A. Servo response for unit step change in fpr set-point For simulating this scenario, control interval is selected as 2 minutes. Weight is selected as 0 for both f and bw, 1 for fpr and Rate weight is selected as 0.4 for fpr. The set-point response for unit step change is shown in fig. 1. The fpr response attains the steady state very soon at about 4 seconds. The response exhibits excellent set-point tracking. B. Effect of unit step change in measured disturbance A step change in the measured disturbance, Consistency, is defined with Initial value = 0, Size = 1, Time = 0. All output set-points set at zero. From the plant output fig. 2, it can be inferred that the outputs deviate very little from their set-points. Due to step change in consistency variable, which is one of the measured disturbance variable, there is a little deviation in the form of overshoot in fpr of peak amplitude 0.26 units, which soon settle down in about nine seconds. Figure 2: plant outputs for feedforward response 160 J OURNAL OF FOREST PRODUCTS & INDUSTRIES, 2014, 3(3), 158-160 ISSN:2325–4513( PRINT) ISSN 2325 - 453X (ONLINE ) A. Comparison of set-point responses for step change in fpr The comparison of set-point responses for step change in fpr is made for the original and the perturbed model. As shown in fig. 3, the set-point tracking for fpr slightly degrades for perturbed system but both responses settles at approximately same time of 12 seconds with the peak time and peak amplitude same for both the models. V. CONCLUSION Multivariable control system analysis of for first pass retention and basis weight in wet end of paper machine is performed using MPC strategy based controller design. Robustness issues are investigated for the subsystems by evaluating the performance after making perturbations in the original system. The setpoint response for unit step change in fpr shows that the fpr response attains the steady state very soon and the response exhibits excellent setpoint tracking. Due to step change in consistency variable, which is one of the measured disturbance variable, there is a little deviation in the form of overshoot in fpr of peak amplitude, which soon settle down. The comparison of setpoint responses for step change in fpr is made for the original and the perturbed model. The setpoint tracking for fpr slightly degrades for perturbed system but both responses settles at approximately same time. The comparison of load responses for step change in consistency disturbance is made for the original process model and the perturbed model. From the comparison responses made by giving step change in one of the measured disturbance, consistency for the original process model and the perturbed model, the conclusion can be made that the disturbance rejection improves for the perturbed model. Figure 3: Comparison of set-point responses for step change in fpr for the original and the perturbed model 1. B. Effect of perturbations on disturbance response The comparison of disturbance responses for step change in consistency disturbance is made for the original process model and the perturbed model as shown in fig. 4.From the comparison responses made by giving step change in one of the measured disturbance, consistency for the original process model and the perturbed model, the conclusion can be made that the disturbance rejection improved for the perturbed model. 2. 3. 4. 5. 6. 7. Figure 4: Comparison of disturbance responses for step change in consistency for the original and the perturbed model REFERENCES Wang, H., Wang A.P. and Duncan, S. R., Advanced Process Control in Paper and Board making, Pira International, 1997. Scott W.E., Principles of Wet End Chemistry, Tappi Press, 1995 Leiviska, K., Paper making science and technology, Process control, Book 14, Finnish Paper Engineers, Association and TAPPI, 1999. Nolelainen, J., Piirainen, R., and White, C, Practical Experiences of white water consistency control of a paper machine wet end, Tappi 1993 Papermakers Conference Proceedings, Tappi press, Atlanta, p.227-238, April 18-21, 1993. Rooke, P.E. and Wang, H. Applying combined neural network and physical modeling to the retention process in papermaking, Appita Journal,Vol.55(4), July, 2002, pp.281-287. Balderud, J. and Wilson, D.I. Parameters affecting disturbance propagation through the wet end of a paper machine, Appita Journal, Vol.58 (1), pp.40-46, 2005. Orccotoma, A.J. Paris, J. and Perrier, M, Paper machine controllability: effect of disturbances on basis weight and first-pass retention, Journal of Process Control, 11, 2001, pp 401-408.