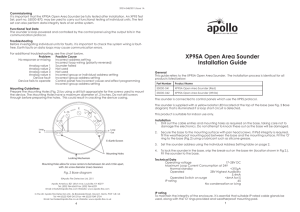

XP95A Sounder Control Module

advertisement

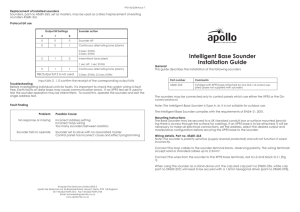

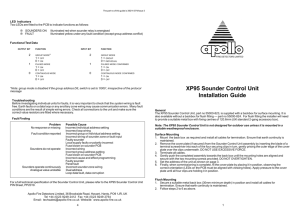

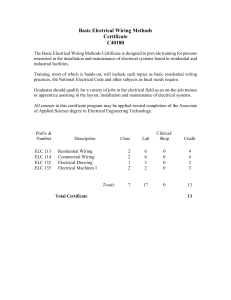

39214-047/2011/Rev 6 Specifications Part Number Compatibility identifier Type Style Dimensions Temperature range Humidity Wiring size Signal line circuit (SLC) Working voltage 55000-825 55000-825 Sounder control module Face plate with screw terminals 4½” x 4½” x 1” 32ºF to 120ºF (0ºC to 49ºC) 10 to 93% RH Non-condensing 24AWG - 14AWG Supervised power limited 17-28 VDC Modulation voltage 5-9V (peak to peak) Supervisory current 1.3mA Surge current 7.5mA Maximum operating current 4mA Functional states Analog level (Normal) 16 Analog level (Trouble) 4* * Local supply failure, notification appliance circuit short/open circuit or group address confl ict. Notification appliance circuit (NAC) Wiring styles Supervised power limited outputs Class A and Class B End-of-line supervisory resistor: 47KΩ, 0.5W (Class B only) External supply Connected between vext + and vext– Monitored input (DC voltage supplies only) Max (NAC) Regulated 24VDC, 1A. Use a regulated power limited DC supply that is listed for fire protection applications. The maximum number of connected devices must be within the output rating. Max NAC Line Loss Maximum line loss when using a NAC supply from a control panel - refer to panel manufactures documentation regarding total allowable line losses. Maximum line loss when using a regulated supply (including wiring from regulated supply to module) - 4VDC when a 24VDC regulated power supply is used. Refer to fi re control panel literature for details on how to achieve audio and visual synchronization. Max (Speakers) 70.7 V rms, 500mA, with wire supervision capability as per NFPA requirements. The speakers used must be listed for fire protection applications. End-of-Line Resistors 47KΩ (A UL listed end-of-line resistor is available from Apollo and can be ordered under part number 44251-146. Functional Test Data Output Bit Function Input Bit Function 2 Group Address Control 1 = Group 0 = Individual 2 Group Address Confi rmation 1 = Group 0 = Individual 1 Not used 1 Indicates Class Wiring 1 = Class B 0 = Class A 0 Sounder Control 1 = On 0 = Off 0 Sounder Status 1 = On 0 = Off ©Apollo Fire Detectors Ltd 1994–2009 Apollo Fire Detectors Ltd, 36 Brookside Road, Havant, Hants, PO9 1JR, UK Tel +44 (0)23 9249 2412 Fax +44 (0)23 9249 2754 Email: techsales@apollo-fire.co.uk Website: www.apollo-fire.co.uk In the USA: Apollo America, 821 Ulrich Ave, Louisville, KY 40219, USA Tel: (502) 964-6565 Fax: (502) 964-6229 Email: infoUSA@apollo-fire.com Website: www.apollo-fire.com 4 XP95A Sounder Control Module Installation Instructions General The XP95A Sounder Control Module, part no 55000-825, monitors and controls a circuit of alarm notification appliances or speakers. It is mounted on a plastic face plate for use with a 4” square or 2 gang electrical box (minimum depth 2⅛”). The module requires a separate 24V dc supply to power notification appliances. In addition to individual Sounder Control Module operation, multiple modules can be controlled simultaneously as a group. A red LED flashes in synchronization with the current pulse reply from the device. Note: the XP95A Sounder Control Module is designed for indoor use only. Control Panel Compatibility The module has been listed by Underwriters Laboratories Inc. for details of compatible control panels contact Apollo Fire Detectors Limited. Please check fi re control panel literature for compatible Apollo devices. Installation These products must be installed in accordance with the applicable NFPA standards, local codes and the authority having jurisdiction. Failure to follow these instructions may result in failure of devices to report an alarm condition. Apollo Fire Detectors Limited is not responsible for devices which are improperly installed, maintained and tested. Before installing these products, check the continuity, polarity and resistance of all wiring. Check that the application is in accordance with the fi re system drawings and conforms to all applicable code requirements. 1. Mount the electrical box as required and install all cables for termination. Ensure that cable shield/earth continuity is maintained. 2. Drill holes in the face plate corresponding to the holes on the mounting box selected (Fig 1). 3. Terminate all cables in compliance with local codes and regulations. 4. Set the address of the module as shown on page 3. 5. Gently push the completed assembly towards the mounting box and align the mounting holes. Secure the unit with the screws provided. Do not overtighten the screws. 6. Commission the module. Speakers If the Sounder Control Module is to be used to drive speakers, the jumper J1 (Fig 2) should be set as indicated. The external supply should be replaced by an audio amplifier with a maximum of 70.7 V rms with supervision capability as per NFPA 72. The speakers connected must be listed for fi re protection applications. 1 Notes 1. Any power supply connected to the Vext I/P should be independent, regulated 24V dc, power limited and listed for fi re protection with battery back-up capability. 2. All circuits are power limited except when used as a speaker circuit, if used remove the lower portion of the power limited label along the kiss cut. Use only limited energy cable types FPL, FPLR or FPLP on power limited circuits. WIRING CLASS A 0 ON 1 2 3 4 5 1 2 4 8 16 6 7 8 32 64 1 B ADDRESS © Apollo Fire Detectors Limited 2004/JDR © Apollo Fire Detectors Limited 2004/JDR/JLC Fig 1. Mounting the XP95A Sounder Control Module Fig 3. DIP Switch, S1 70.7 VAC RMS@ 500mA JUMPER SET TO ‘SPEAKER’ SPEAKERS CLASS A WIRING OUTPUT CIRCUIT VEXT – A/B - A - A+ – A/B+ Speaker VEXT + – + + AUDIO DAISY CHAIN TO NEXT DEVICE – Signal COMMUNICATIONS IN LOOP 47K, ½W, 5% EOL COMMUNICATIONS OUT LOOP L2+ L1– SPEAKER/NOTIFICATION APPLIANCE 24VDC SIGNALING DEVICE HORNS, BELLS, STROBES etc. 1 AMP MAX CLASS A WIRING JUMPER SET TO ‘SIGNAL’ OUTPUT CIRCUIT VEXT – OR A/B - A - A+ – A/B+ Speaker + Speaker operation . . . . . . J1 J1 © Apollo Fire Detectors Limited 2007-10/TB/EKC + 24VDC IN 24VDC TO NEXT DEVICE – Signal COMMUNICATIONS IN LOOP COMMUNICATIONS OUT LOOP 47K, ½W, 5% EOL L2+ Signal operation VEXT + – J1 – CLASS B WIRING DIP switch setting addr 1234567 DIP switch setting addr 1234567 DIP switch setting addr 1234567 DIP switch setting addr 1234567 DIP switch setting 1234567 1 2 3 4 5 6 7 8 9 10 1000000 0100000 1100000 0010000 1010000 0110000 1110000 0001000 1001000 0101000 11 12 13 14 15 16 17 18 19 20 1101000 0011000 1011000 0111000 1111000 0000100 1000100 0100100 1100100 0010100 21 22 23 24 25 26 27 28 29 30 1010100 0110100 1110100 0001100 1001100 0101100 1101100 0011100 1011100 0111100 31 32 33 34 35 36 37 38 39 40 1111100 0000010 1000010 0100010 1100010 0010010 1010010 0110010 1110010 0001010 41 42 43 44 45 46 47 48 49 50 1001010 0101010 1101010 0011010 1011010 0111010 1111010 0000110 1000110 0100110 51 52 53 54 55 56 57 58 59 60 1100110 0010110 1010110 0110110 1110110 0001110 1001110 0101110 1101110 0011110 61 62 63 64 65 66 67 68 69 70 1011110 0111110 1111110 0000001 1000001 0100001 1100001 0010001 1010001 0110001 71 72 73 74 75 76 77 78 79 80 1110001 0001001 1001001 0101001 1101001 0011001 1011001 0111001 1111001 0000101 81 82 83 84 85 86 87 88 89 90 1000101 0100101 1100101 0010101 1010101 0110101 1110101 0001101 1001101 0101101 91 92 93 94 95 96 97 98 99 100 1101101 0011101 1011101 0111101 1111101 0000011 1000011 0100011 1100011 0010011 101 102 103 104 105 106 107 108 109 110 1010011 0110011 1110011 0001011 1001011 0101011 1101011 0011011 1011011 0111011 111 112 113 114 115 116 117 118 119 120 1111011 0000111 1000111 0100111 1100111 0010111 1010111 0110111 1110111 0001111 121 122 123 124 125 126 1001111 0101111 1101111 0011111 1011111 0111111 addr AUDIO IN J1 – CLASS B WIRING Address Setting Segments 1-7 of the DIP switch are used to select the address of the module. Each of the seven segments must be set to ‘0’ (ON) or ‘1’ (OFF) using a small screwdriver or similar tool. A complete list of address settings is shown below. (The eighth segment of the switch is used to select Class A or B wiring) Group Address Setting In Group mode the Sounder Control Module responds to an additional address referred to as the ‘group address’, which is used to activate groups of Sounder Control Modules simultaneously. (The module continues to respond to its own individual address and report its status from that address in the normal way.) The group address is selected by the four-segment DIP switch S2 which is factory-set to 0000. A group address may be any spare address within - and only within - the range 112 to 126 inclusive. The required group address is set by moving one or more of the segments on the switch to ‘1’ (OFF). The table shows the settings for the group address switch: L1– addr Fig 2. Wiring diagram for XP95A Sounder Control Module 2 112 113 114 115 116 117 118 119 120 DIP switch setting addr 1248 1111 121 0111 122 1011 123 0011 124 1101 125 0101 126 1001 0001 1110 DIP switch setting 1248 0110 1010 0010 1100 0100 1000 0 ON 1 2 3 4 S2 1 2 4 8 1 GROUP ADDRESS © Apollo Fire Detectors Limited 2004/JDR Fig 4. DIP Switch, S2 3