XP95 Sounder Control Unit Installation Guide

advertisement

The part no of this guide is 39214-074/Issue 3

LED Indicators

Two LEDs are fitted to the PCB to indicate functions as follows:

! SOUNDERS ON

! FAULT

Illuminated red when sounder relay is energised

Illuminated yellow under any fault condition (except group address conflict)

Functional Test Data

OUTPUT BIT

FUNCTION

INPUT BIT

FUNCTION

2

GROUP MODE*

2

GROUP MODE

1

PULSED MODE

1

PULSED MODE CONFIRMED

CONTINUOUS MODE

0

0

1 = OFF

0 = ON

1 = ON

0 = OFF

1 = ON

0 = OFF

1 = GROUP

0 = INDIVIDUAL

1 = ON

0 = OFF

CONTINUOUS MODE CONFIRMED

1 = ON

0 = OFF

*Note: group mode is disabled if the group address DIL switch is set to ‘0000’, irrespective of the protocol

message

Troubleshooting

Before investigating individual units for faults, it is very important to check that the system wiring is fault

free. Earth faults on a data loop or any ancillary zone wiring may cause communication errors. Many fault

conditions are the result of simple wiring errors. Check all connections to the unit and make sure the

correct value resistors are fitted where necessary.

Fault Finding

Problem

No response or missing

Fault condition reported

Sounders do not operate

Sounders operate continuously

Analogue value unstable

FIRE DETECTORS LIMITED

Possible Cause

Incorrect individual address setting

Incorrect loop wiring

Incorrect group or individual address setting

Incorrect wiring of sounder zone or fault input

Faulty sounder

Local supply faulty or polarity incorrect

Fuse blown on sounder PCB

Incorrect wiring

Incorrect group address setting

Fuse blown on sounder PCB

Incorrect cause and effect programming

Faulty sounder

Panel fault

Incorrect sounder zone wiring

Dual address

Loop data fault, data corruption

For a full technical specification of the Sounder Control Unit, please refer to the XP95 Sounder Control Unit

PIN Sheet, PP2019.

XP95 Sounder Control Unit

Installation Guide

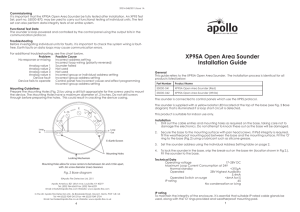

General

The XP95 Sounder Control Unit, part no 55000-823, is supplied with a backbox for surface mounting. It is

also available without a backbox for flush fitting — part no 55000-824. For flush fitting the installer will need

to provide a suitable metal box with fixing centres of 120.6mm (UK standard 2-gang accessory box).

Note: The XP95 Sounder Control Unit is not designed for outdoor use unless it is mounted in a

suitable weatherproof enclosure.

Surface Mounting

1. Mount the back box as required and install all cables for termination. Ensure that earth continuity is

maintained.

2. Remove the cover plate (if secured) from the Sounder Control Unit assembly by inserting the blade of a

terminal screwdriver into each of the four securing clips in turn, gently prising the outer edge of the cover

plate over the clips underneath. DO NOT USE EXCESSIVE FORCE.

3. Terminate all cables.

4. Gently push the completed assembly towards the back box until the mounting holes are aligned and

secure with the two mounting screws provided. DO NOT OVERTIGHTEN.

5. Set the address of the unit as shown on page 3.

6. Finally, when commissioning is complete, fit the cover plate by placing it in position, observing the

correct orientation (LEDs on the PCB must be aligned with viewing holes). Apply pressure to the cover

plate until all four clips are holding it in position.

Flush Mounting

1. Secure a suitable metal back box (30mm minimum depth) in position and install all cables for

termination. Ensure that earth continuity is maintained.

2. Follow steps 2 to 6 as above.

Apollo Fire Detectors Limited, 36 Brookside Road, Havant, Hants, PO9 1JR, UK

Tel +44 (0)23 9249 2412 Fax +44 (0)23 9249 2754

Email: techsales@apollo-fire.co.uk Website: www.apollo-fire.co.uk

4

1

addr

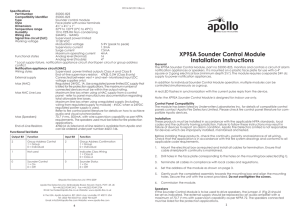

Wiring Details

All wiring terminals accept solid or stranded cables up to 2.5mm².

LOCAL POWER SUPPLY

L2 (+ve)*

SOUNDER –

L1 (–ve)*

SOUNDER +

Vex –

Vex +

{

{

NORMALLY CLOSED

FAULT CONTACT

FUSE

N/C

COM

N/O

FAULT

INPUT

FAULT INPUT NOT

USED (WIRE LINK

MUST BE FITTED)

NORMALLY OPEN

FAULT CONTACT

{

{

SOUNDERS WITH

POLARISING DIODES

XP95 LOOP

10KΩ

EOL

DIL switch

setting

1234567

Address Setting

The Sounder Control Unit is designed to be polled by the control panel in two ways, individually or as part of

a group. Two DIL switches are provided for setting the addresses.

DIL switch

setting

1234567

addr

DIL switch

setting

1234567

addr

DIL switch

setting

1234567

11

12

13

14

15

16

17

18

19

20

1101000

0011000

1011000

0111000

1111000

0000100

1000100

0100100

1100100

0010100

21

22

23

24

25

26

27

28

29

30

1010100

0110100

1110100

0001100

1001100

0101100

1101100

0011100

1011100

0111100

31

32

33

34

35

36

37

38

39

40

1111100

0000010

1000010

0100010

1100010

0010010

1010010

0110010

1110010

0001010

41

42

43

44

45

46

47

48

49

50

1001010

0101010

1101010

0011010

1011010

0111010

1111010

0000110

1000110

0100110

51

52

53

54

55

56

57

58

59

60

1100110

0010110

1010110

0110110

1110110

0001110

1001110

0101110

1101110

0011110

61

62

63

64

65

66

67

68

69

70

1011110

0111110

1111110

0000001

1000001

0100001

1100001

0010001

1010001

0110001

71

72

73

74

75

76

77

78

79

80

1110001

0001001

1001001

0101001

1101001

0011001

1011001

0111001

1111001

0000101

81

82

83

84

85

86

87

88

89

90

1000101

0100101

1100101

0010101

1010101

0110101

1110101

0001101

1001101

0101101

91

92

93

94

95

96

97

98

99

100

1101101

0011101

1011101

0111101

1111101

0000011

1000011

0100011

1100011

0010011

101

102

103

104

105

1010011

0110011

1110011

0001011

1001011

106

107

108

109

110

0101011

1101011

0011011

1011011

0111011

111

112

113

114

115

1111011

0000111

1000111

0100111

1100111

116

117

118

119

120

0010111

1010111

0110111

1110111

0001111

121

122

123

124

125

126

1001111

0101111

1101111

0011111

1011111

0111111

Group Address Setting

In Group mode the Sounder Control Unit responds to an additional address referred to as the “group

address”, which is used to activate groups of Sounder Control Units simultaneously. (The unit continues to

respond to its own individual address and report its status from that address in the normal way.) The group

address is selected by the four-segment DIL switch which is factory-set to 0000. A group address may be

any spare address within – and only within – the range 112 to 126 inclusive. The required group address is

set by moving one or more of the segments on the switch to “1”. The following table shows the settings for

the group address switch.

Fuse: 1.25A, anti-surge Local supply: 24V (9V min, 32V max) Sounder zone end-of-line resistor: 10KΩ, ¹/3Watt

2.6mA

1.9mA

1.7mA

3.6mA

addr

1000000

0100000

1100000

0010000

1010000

0110000

1110000

0001000

1001000

0101000

addr

switch-on surge, max 100 mS

quiescent

sounders operated

fault

DIL switch

setting

1234567

1

2

3

4

5

6

7

8

9

10

* L1 and L2 are polarity insensitive, but, for the sake of consistency, it is recommended that L1 be kept negative

Maximum current consumption at 24V

addr

112

113

114

115

116

117

118

119

120

DIL switch

setting

1248

1111

0111

1011

0011

1101

0101

1001

0001

1110

addr

121

122

123

124

125

126

DIL switch

setting

1248

0110

1010

0010

1100

0100

1000

Note: one switch is sealed with a sticky label. This label should not be removed unless the unit is to be

controlled as part of a group.

Commissioning

It is important that the Sounder Control Unit be fully tested after installation. An XP95 Test Set, part no

55000-870, may be used to carry out functional testing of individual units. It can also be used to perform

data integrity tests of an entire system.

Individual Address Setting

The individual address of the Sounder Control Unit is set using the seven-segment DIL switch. Each segment

of the switch must be set to “0” or “1”, using a small screwdriver or similar tool. A complete list of address

settings is shown opposite.

The cause and effect programming (the control panel software responsible for switching sounders and

outputs etc. in alarm condition) should be fully checked, along with all equipment connected to the Sounder

Control Unit.

2

3