An Investigation of Ethanol Fermentation in Yeast

advertisement

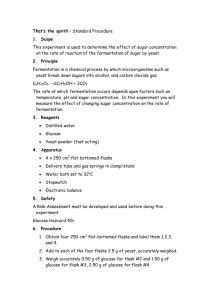

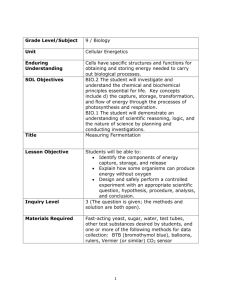

General Biology II – Major Life Processes in Plants and Animals An Investigation of Ethanol Fermentation in Yeast Adapted From: George E. Glasson and Woodrow L. McKenzie. Investigative Learning in Undergraduate Freshman Biology Laboratories. JCST Dec 1997/Jan 1998 Steven Spilatro. Yeast on the Rise: Investigative Study of Fermentation in the Introductory Biology Classroom. Tested Studies for Laboratory Teaching This lab activity is intended to provide an opportunity for students… • • • • To examine some parameters that affect ethanol fermentation by yeast To practice designing experiments that examine a research question To practice gathering, interpreting and presenting data To gain experience with oral presentations Objectives: This lab aims to contribute to the development of the following components of the Cégep Champlain St.Lawrence Science Program Graduate Profile: I. Apply The Experimental Method II. Take A Systematic Approach To Problem Solving III. Use The Appropriate Information Technologies IV. Reason Logically V. Communicate Effectively VI. Learn In An Autonomous Manner VII. Work As Members Of A Team VIII. Make Connections Between Science, Technology and Social Progress X. Become Familiar With the Context in Which Scientific Concepts are Discovered and Developed XI. Develop Attitudes Appropriate For Scientific Work XII. Apply What They Have Learned To New Situations This lab also contributes to the attainment of the following elements of the 00XU objective: 1. 3. To analyze the relationship between structure and function in multicelled organisms To explain the function of conservation, regulation and reproduction in multicelled organisms. This lab also contributes to the development of the follow performance criteria of the 00XU objective: • Proper use of concepts and terminology • Clear description of the main stages in a biological process • Description of cellular processes of transformation of matter and energy • Clear description of the factors that influence the transformation of matter and energy • Use of techniques of observation or experimentation • Observance of the experimental method and, where applicable, the experimental procedure • Adherence to safety and environmental protection regulations Prelab Bring graph paper to lab Background Information from Raven, P.H. and G.B. Johnson 2002. Biology 6th Edition. McGraw-Hill. Anaerobic Respiration In the presence of oxygen, cells can respire aerobically, using oxygen to accept the electrons harvested from food molecules. In the absence of oxygen some organisms can respire anaerobically, using inorganic molecules to accept the electrons. For example, many bacteria use sulfur, nitrate, or other inorganic compounds as the electron acceptor in place of oxygen. Fermentation In the absence of oxygen, aerobic metabolism cannot occur, and cells must rely exclusively on glycolysis to produce ATP. Under these conditions, the hydrogen atoms generated by glycolysis are donated to organic molecules in a process called fermentation. Eukaryotic cells are capable of only a few types of fermentation. In one type, which occurs in singlecelled fungi called yeast, the molecule that accepts hydrogen from NADH is pyruvate, the end product of glycolysis itself. Yeast enzymes remove a terminal CO2 group from pyruvate through decarboxylation, producing a two-carbon molecule called acetaldehyde. The CO2 released causes bread made with yeast to rise, while bread made without yeast (unleavened bread) does not. The acetaldehyde accepts a hydrogen Fermentation and Biofuels 1 atom from NADH, producing NAD+ and ethanol (ethyl alcohol). This particular type of fermentation is of great interest to humans, since it is the source of the ethanol in wine and beer. Ethanol and CO2 are byproducts of fermentation. 2 ADP 2 ATP glycolysis glucose 2 ethanol 2 NAD+ 2 NADH CO2 pyruvate 2 acetaldehyde Figure 1. Alcohol fermentation in yeast The Lab Activity One of the many industrial applications of fermentation is the production of biofuels. Biofuels such as ethanol and biodiesel are considered environmentally-friendly alternatives to fossil fuels because they are renewable and produce fewer emissions and greenhouse gasses. (See the Bio 2 Web page for more information on biofuel production and use in Canada) Although the industrial production of biofuels requires many procedures, it is still based on the basic principles of fermentation. As a class, we will try to determine the optimal conditions for some factors that affect fermentation. The first week will be devoted to becoming familiar with the procedure. In addition, each group will be assigned one of the following factors to test during the second week: 1. 2. 3. 4. 5. 6. 7. 8. Type of carbohydrate: compare fermentation of glucose, sucrose, lactose, etc. Concentration of glucose: compare fermentation using glucose concentrations from 0 to 5% Concentration of salt: compare fermentation in 0% to 10% salt environments Acid environment: compare fermentation in acidic environments pH 2 – pH 7 Alkaline environment : compare fermentation in basic environments pH 7 to pH 12 Temperature: compare fermentation at temperatures from 4°C to 60°C. Variety of yeast: compare fermentation of different varieties of yeast Ethanol concentration: compare fermentation in 0% - 10% ethanol environments Note: It may be possible to choose the factor your group will examine. The earlier you choose, the more likely you will get what you want. The Lab Assignment Each team will orally present the results and conclusions of their study to the class. The experimental protocol used and raw data gathered will be submitted in writing. Materials All groups will have access to the following solutions and equipment: yeast in solution (8% yeast in dH2O) balances and weigh boats distilled water alternative varieties of yeast glucose 2, 1 ml pipettes attached together test tube rack controlled temperature water bath range of pH buffers glucose and other simple carbohydrates Fermentation and Biofuels 50 ml flask 5 ml syringe salt stop watches 10 ml pipette 2 WEEK 1 - Designing the Tests – Common Procedure Fermentation produces two by-products: ethanol and carbon dioxide. Although we are interested in the production of ethanol, it is much easier to measure the CO2 released and use it as an indicator of fermentation. Fermentation will take place in a syringe and the gas produced (CO2) will be collected in 1 mL pipettes. 1. Weigh out 1.0 g of glucose and place it in a 50 mL flask. 2. Add 10 mL of distilled water to the flask and gently swirl until the glucose is completely dissolved. 3. Transfer 10 mL of the yeast suspension (8% yeast in water) into the flask. 4. Allow the yeast suspension to incubate for 5 minutes, with occasional swirling. 5. Use a 5 mL syringe to take up 3 mL of the yeast suspension. Invert the syringe and take in 1 mL of air above the liquid. pipette 6. Add a small drop of water to the assembled 1 mL pipettes. 7. Allow the drop to reach the 0 mark and attach the pipettes to the yeast-filled syringe. (Figure 1) 8. As CO2 is released the water bubble will rise. Record the position of the bubble at 2minute intervals (more frequently if CO2 production is rapid.) 9. Plot the raw data on graph paper, and draw a line through the linear part of the curve. Using only the linear part of the data, calculate the slope of the line as change in volume ÷ change in time. This yields the rate of respiration as milliliters of CO2 per minute. water droplet 10. Record the rate of respiration in the class data sheet so that a class average can be calculated. Table 1. Sample raw data Time (sec) 0 3 6 7 8 9 11 Reading (ml) 0.18 0.25 0.38 0.48 1 0.55 0,9 0.65 0.84 1 ml air Rate = 0.54/6 = 0.09 ml/min 3 ml yeast 0,8 0,7 0.54 ml ml CO2 0,6 0,5 0,4 6 min syringe 0,3 0,2 Figure 1. Set up for yeast fermentation experiment 0,1 0 0 2 4 6 8 10 12 14 minutes Fermentation and Biofuels Figure 2. Example of how to graph fermentation raw data. The raw data (Table 1, the actual CO2 volume measurements) is graphed as shown. Note that the rate of fermentation is calculated from the slope of the line drawn through the linear part of the curve. 3 WEEK 1 - Designing the Tests – Group Procedure Determine how you will perform your assigned experiment. Perform trial runs. You may wish to represent your data graphically. Does it make sense? Can it be interpreted and explained logically? Modify your protocol as needed to obtain meaningful results. WEEK 2 - Experimentation Perform experiments designed during week one. Written Assignment Due March 27, 2008 Write up a detailed description of the procedure you designed. Provide tables of all data gathered. Summarize data graphically. Oral Presentation Assignment Due March 27, 2008 Present the results of your study to the class in a 10-minute (max!) presentation Include: What parameter did your team study? Provide a VERY brief description of your experimental protocol. You only need to describe the differences between your protocol and the common procedure. Summarize your results graphically. Explain the implications of your results to the industrial production of ethanol. To avoid delays, students will not be allowed to log on to the lab computer. If you wish to use the digital projector for your oral presentation you may a. Send to my e-mail address (adera@slc.qc.ca) a clearly labeled PowerPoint file you wish to present by noon, Thursday, March 27. To facilitate the presentations, I will download all files received into a single folder. b. Alternatively, you may access your file from your USB key, providing you have previously verified that the lab computer is able to recognize your key. USB keys that have not been “recognized” by the lab computer prior to the presentation time will not be accepted. Peer Evaluation Each member of your lab group must complete a Peer Evaluation report and hand it in separately from the lab report. Fermentation and Biofuels 4