Panasonic EYG-S091310 datasheet

advertisement

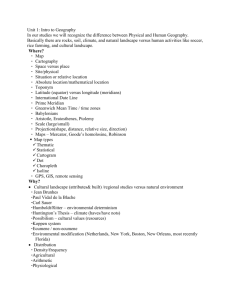

“PGS” Graphite Sheets “PGS” Graphite Sheets Type: EYG PGS (Pyrolytic Graphite Sheet) is a thermal interface material which is very thin, synthetically made, has high thermal conductivity, and is made from a higly oriented graphite polymer film. It is ideal for providing thermal management/heat-sinking in limited spaces or to provide supplemental heat-sinking in addition to conventional means. This material is flexible and can be cut into customizable shapes. ■ Features ● Excellent thermal conductivity (2 to 4 times as high as copper, 3 to 6 time as high as aluminum) ● Lightweight: Specific gravity : 0.85 to 2.1 g/cm3 (1/4 to 1/10 of copper, 1/1.3 to 1/3 of aluminum in density) ● Flexible and easy to be cut or trimmed. (withstands repeated bending) ● Low thermal resistance ● RoHS compliant ■ Recommended applications ● Notebook PCs, DVDs, DVCs, mobile phones ● Semiconductor manufacturing equipment (Sputtering, Dry etching, Steppers) ● Optical communications equipment ■ Handling Precautions (See Page 211) ■ Explanation of Part Numbers 1 2 3 4 5 6 7 8 9 10 E Y G S 1 8 2 5 1 0 Product Code 11 Dimension X (Short) Dimension Y (Long) Style S A C M 12 Suffix Thickness (mm) PGS only Taping Coating Other materials laminated 10 07 03 0.1 0.07 0.025 ■ Dimensions in mm (not to scale) Standard size Dimension X (Short) Dimension Y (Long) Thickness EYGS1823첸첸 180±5 mm 230±5 mm 0.10±0.03, 0.07±0.015, 0.025±0.010 mm EYGS1218첸첸 115±5 mm 180±5 mm 0.10±0.03, 0.07±0.015, 0.025±0.010 mm EYGS0912첸첸 90±5 mm 115±5 mm 0.10±0.03, 0.07±0.015, 0.025±0.010 mm X(mm) Y(mm) Part No. ■ Characteristics Characteristics Specification Specification Specification 0.10 ± 0.03 mm 0.07 ± 0.015 mm 0.025 ± 0.010 mm 0.85 g/cm3 1.1 g/cm3 2.1 g/cm3 600 to 800 W/(m·K) 750 to 950 W/(m·K) 1500 to 1700 W/(m·K) 10000 S/cm 10000 S/cm 20000 S/cm 19.6 MPa 22.0 MPa 30.0 MPa a-b plane 9.3 ҂ 10 1/K 9.3 ҂ 10 1/K 9.3 ҂ 10-7 1/K c axis 3.2 ҂ 10 1/K 3.2 ҂ 10 1/K 3.2 ҂ 10-5 1/K Thickness Density Thermal conductivity a-b plane Electrical conductivity Extensional strength Expansion coefficient Heat resistance Bending(angle 180,R5) -7 -5 -7 -5 400 °C 10000 cycles Design and specifications are each subject to change without notice. Ask factory for the current technical specifications before purchase and/or use. Should a safety concern arise regarding this product, please be sure to contact us immediately. Feb. 2006 “PGS” Graphite Sheets ■ Thermal conductivity of PGS compared to other ■ Layered structure of PGS materials (Thickness : PGS 0.1 mm type) Thermal conductivity: Twice as high as copper, Specific gravity:1/9 that of copper (1/3 that of aluminum) 3.354 to 3.356 ҂10-8cm C axis PGS Conventional graphite Pure copper (hard) Aluminum Pure iron Stainless steel Magnesium alloy Heat-conductive sheet Silicon nitride Aluminum nitride Silicon carbide Glass epoxy a-b plane Polyimide 0 100 200 300 400 500 600 700 800 Coefficient of thermal conductivity (W/(m·k)) ■ Dimensions in mm (Thickness : PGS 0.1 mm type) Adhesive type Type 1PGS only PGS 2 Insulative strong adhesion type PGS 3 Insulative thin adhesion type PGS Insulation type 4 Low thermal 5 High heatresistance resistance type type PGS 6 Polyester tape type PGS PGS 7 Polyimide tape type PGS Multilayered type 8 One-side type 9 Doubleside type PGS PGS Silicon 0.1 mm Silicon 0.1 mm Structure Acrylic double-sided adhesive tape 0.03 mm Separating paper Acrylic Acrylic Separating Polyester tape Polyimide tape adhesive double-sided paper 0.03 mm 0.03 mm 0.01 mm adhesive tape 0.01 mm Separating Heat-resistance acrylic adhesive tape Separating paper 0.03 mm paper Thickness 0.10 mm 0.13 mm 0.11 mm 0.11 mm 0.13 mm 0.13 mm 0.13 mm 0.20 mm 0.30 mm Thermal conductivity 600 to 800 W/(m·K) 500 to 600 W/(m·K) 500 to 600 W/(m·K) 550 to 600 W/(m·K) 500 to 600 W/(m·K) 500 to 600 W/(m·K) 500 to 600 W/(m·K) 250 to 300 W/(m·K) 250 to 300 W/(m·K) Withstand temperature 400 °C 85 °C 85 °C 85 °C 150 °C 85 °C 180 °C 180 °C 180 °C Standard sample 180҂230 mm 90҂115 mm 90҂115 mm 90҂115 mm 90҂115 mm 90҂115 mm 90҂115 mm 115҂180 mm 115҂180 mm Part No. EYGS182310 EYGA091210A EYGA091210B EYGC091210C EYGA091210T EYGA091210P EYGA091210K Features · Usable up to · lnsulation 400 °C · Strong · Low Thermal adhesion resistance ·Electrically Conductive · lnsulation · Thin film adhesion · Low thermal · High heatresistance resistance EYGM121810SS EYGM121810SW · High mechani- · High mechani- · Cushioning cal strength cal strength Properties · Cushioning Properties ✽ Please contact our engineering section or factory about to special applications. Design and specifications are each subject to change without notice. Ask factory for the current technical specifications before purchase and/or use. Should a safety concern arise regarding this product, please be sure to contact us immediately. Feb. 2006

![Introduction [max 1 pg]](http://s3.studylib.net/store/data/007168054_1-d63441680c3a2b0b41ae7f89ed2aefb8-300x300.png)