ISE509

Subject Description Form

Subject Code

Subject Title

ISE509

Auditing and Registration of Quality Systems

Credit Value 3

5 Level

Pre-requisite/Corequisite/ Exclusion

Experience in QC, QA, quality management, or other related operational activities is desirable.

Exclusion subject LGT5159 Implementation and Auditing of Management

Systems

Objectives This subject provides students with

1.

managerial skills for interpreting the requirements of the ISO 9000 quality management system standards and their application, taking into account customer satisfaction and stakeholders’ interest in a company for the purpose of continual improvement in effectiveness and efficiency;

2.

managerial skills in the auditing and management review of quality management systems, identification of nonconformities and improvement opportunities, preventive and corrective action to rectify nonconformities, and realisation of opportunities;

3.

managerial knowledge, including an understanding of the underlying processes and key success factors of assisting a company to gain and maintain third party ISO 9001 certification in an effective and efficient manner;

4.

managerial knowledge, including an understanding of the underlying processes and key success factors of integrating a quality management system with the other relevant management systems of a company to achieve organisational effectiveness and efficiency.

Intended Learning

Outcomes

Upon completion of the subject, students will be able to a.

examine various existing work and managerial situations in quality management with reference to ISO 9000 standards and organisational issues, and formulate a quality management system that will enhance customer satisfaction and firm efficiency and effectiveness; b.

identify, select, and apply appropriate quality management system practices to improve existing or design new work/management methods and procedures with a wider quality perspective; c.

apply quality audit and management review techniques to identify quality management system nonconformities and improvement opportunities, and apply problem-solving techniques for corrective action;

28.8.2013

d.

apply ISO 9000 certification practices and managerial skills to develop and implement a quality management system in a company that is seeking third party registration; e.

critically examine and apply techniques to integrate a quality management system with the other management systems of a company.

Subject Synopsis/

Indicative Syllabus

1. Quality Management Systems

Evolution of approaches to quality management; ISO principles of quality management; framework for achieving TQM: the ISO 9000 series of standards, structure, and basic concepts. Process approach.

2. Elements of Quality Management Systems (ISO 9000 Model)

Management responsibility; resource management, product realisation, contract review; design control; document control; purchasing; purchaser supplied product; product identification and traceability; process control; inspection and testing; inspecting, measuring, and testing equipment; inspection and testing status; control of nonconforming products; corrective action; quality records; internal audits; training; servicing; statistical techniques; integration with other management systems including ISO 14001.

3. Quality Audits

Different types of audits; audit principles; preparing for an audit; conduct of an audit; identification of nonconformances; preparation of reports; follow-up action; examples.

4.

Registration of Quality Management Systems

Registration bodies and their accreditation procedures; schemes and general principles of registration; documentation of quality systems: quality manual, manufacturing operation procedures, manufacturing instructions, and quality records; audit visit preparation; post certification obligations. Typical problems in quality systems. Keys to successful registration; benefits of quality system registration.

Teaching/Learning

Methodology

A mixture of lectures, seminars, tutorial exercises, and case studies is used to deliver the various topics in this subject. Some material is covered using a problem-based format that incorporates complex organisational issues, where this advances the learning objectives. Other material is covered through directed study and discussion questions related to contemporary or cultural issues in quality management systems to enhance students’ “learning to learn” ability. Seminars featuring guest speakers from registration bodies, consultants, or members of companies with registered systems are organised at which experts present their experience in audits and system registration. Some case studies, largely based on consultancy experience, are used to integrate these topics and demonstrate to students how the various elements in the system are interrelated and applied in real-life situations in a company.

28.8.2013

Teaching/Learning

Methodologies

Lecture

Tutorial

Seminars

Project/case studies

Assessment Methods in Alignment with

Intended Learning

Outcomes

Specific assessment methods/tasks

1. Assignments

2. Case studies

3. Test

4. Examination

Total

Student Study

Effort Expected

Reading List and

References

28.8.2013

Intended Subject Learning Outcomes to be assessed a

b

c

d

e

% weighting

Intended subject learning outcomes to be assessed

21%

21%

18%

40%

100% a b c d e

The case studies are aimed at assessing students’ ability to examine work situations, identify quality management system nonconformities, apply problem-solving techniques for corrective action, and improve existing or design new work methods and procedures with a wider quality perspective. The test and examination are aimed at assessing the knowledge and skills gained by the students.

Class contact:

Lectures/Seminars 3 hours/week for 10 weeks

Tutorials/Case studies 3 hours/week for 3 weeks

Other student study effort:

Studying and self-learning

Assignment, case study and report writing

30 Hrs.

9 Hrs.

45 Hrs.

30 Hrs.

Total student study effort

1.

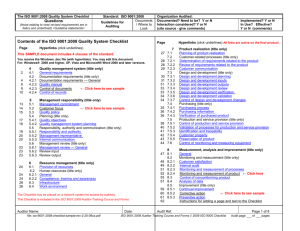

ISO 9000-9004 (Latest revision)

114 Hrs.

2.

West, Jack, Ciansrani, Charles A. and Disakalf, Joseph J. 2009, ISO

9001:2008 , 3 rd edn, ASQ Press

3.

Tricker, Ray 2010, ISO 9001:2008 for Small Business , Oxford

4.

The Quality Management Journal, ASQ Press

5.

Quality Progress, ASQ Press

6.

Web Sites: www.iso.org

28.8.2013