QMSintroduction

advertisement

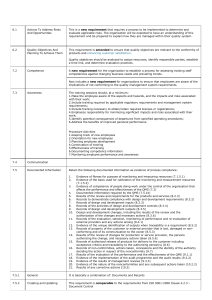

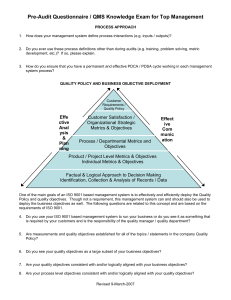

Introduction to Quality Management Systems This training is to: Provide a basic understanding of quality management systems (QMS) as applied in Clinical Oncology. ESSENTIAL VOCABULARY To understand the ISO9000 standard, there are certain terms you should become familiar with. • Supplier – An organization that provides a ‘product’ (a product can be a service!); e.g. the treatment radiographers supply a treatment service. • Customer – The recipient of a product; e.g. the treatment radiographers are customers of the treatment planning service. • Product – The result of a process. • Process – A set of interrelated, or interacting, activities that transform inputs into outputs. Procedures form part of Processes. e.g. the patient journey through clinical evaluation. • Procedure – A specified way to carry out an activity or process. • Audit – The systematic, independent and documented process for obtaining evidence and evaluating it objectively to determine the extent to which specified criteria are fulfilled. ESSENTIAL VOCABULARY 2 • Nonconformity – The non-fulfilment of a requirement of the system. (Alternatively: non-conformance) The department Quality Management Representatives (QMRs) usually decide whether a reported ‘observation’ is a nonconformity. • Corrective action – Action to eliminate the cause of a detected nonconformity. • Preventive action – Action to eliminate the cause of a potential nonconformity, or other undesirable situation. • Nonconformity/Corrective Action Report (NCAR) – A document recording information about nonconformities and their corrective actions. • Issue Report - A document recording information about a treatment “issue” and its resolution. • Opportunity for Improvement – A recorded suggestion, observation or non-treatment “issue”. Can lead to Corrective or Preventive actions. • Deviation permit – permission to depart from a specified requirement (sometimes also referred to as a concession; strictly a concession is a permit to release nonconforming product). INTRODUCTION TO ISO 9000 For those that may remember: Under the 1994 standard there were three models in the series: ISO 9001, 9002, and 9003; and each model had a slightly different scope. Now: Under the 2000 revision of the standard there is now only ISO9001 with 8 sections, and an organization must examine its activities and document any relevant exclusions from (section 7 of) the standard that applies to their quality management system. ISO9004 is published as guidelines for performance improvement. Remember: ISO 9000 is intended to be relevant to all types of organizations. Whether manufacturing industries as diverse as medical equipment, pharmaceuticals, or paper pulp, or service industries such as medicine, banking, or transportation, the ISO 9001 quality system model is applicable to all products and services. ISO 9001:2000 Most headings have sub-headings e.g. Product realization Planning of product realisation Customer-related processes Design and development Purchasing Production and service provision Control of monitoring and measuring devices WHAT IS QUALITY? Quality has been defined as: • “The totality of features and characteristics of a product or service which bear on its ability to satisfy stated or implied needs.” ISO 8402:1994. • The “degree to which a set of inherent characteristics fulfils requirements” ISO 9001:2000 Quality has also been summed up by the phrase; FITNESS FOR PURPOSE. Meaning the product or service is neither less nor more than the customers given need. Hence quality could also be thought of as: Fitness for purpose, delivery of customer satisfaction, Delivering an agreed service to an agreed standard, or, … ? Whether the quality of a service, or product, is appropriate depends on the need(s) it is meant to fulfil. In meeting the need(s) of a service user (‘customer’) you must include, not only what the service is required to do, but also as appropriate; price, delivery, supporting service and un-stated customer expectation/desires. HOW DO WE ACHIEVE QUALITY? Following a well publicised incident in the late 1980’s Radiotherapy departments in the UK were given guidance from the Department of Health to implement quality assurance systems based on the ‘QART’ report of May 1991 (itself based on BS5750/ISO9000). This was followed by an ESTRO report in the late 1990’s making similar recommendations based on ISO9000:1994. We have implemented a quality management system since 1996, currently conforming to the ISO 9001:2000 standard (originally ISO 9001:1994), which is designed to allow us to deliver quality based on the eight quality management principles: and … HOW DO WE ACHIEVE QUALITY? 2 and following the ‘Quality Cycle’: Define Quality Objectives Establish Process Modify Process Audit Process Sometimes also referred to as the Plan – Do – Check – Act cycle. This cycle has also been brought to the fore in the Health Service as the plan/do/study/act cycle by Service Improvement Teams; or the similar, review/agree/implement/demonstrate model in Clinical Governance. HOW DO WE ACHIEVE QUALITY? 3 We have implemented a “Quality Management System” (QMS), it is often referred to as a “Quality System”, but it is probably best-understood if it is thought of as a “Management System”. It is also worth noting that we are ‘certified’ or ‘certificated’ to ISO9001:2000, while it is our Certification Body (BSI) that is accredited. In Clinical Oncology the system is lead by the Management Review Meeting (all Clinical Oncologists, Heads of Staff Groups, Quality Management Representatives & a couple of others) held twice a year with feedback through Clinical Oncology Department meetings & Radiotherapy meetings. DOCUMENTATION Documentation is essential to quality systems. It explains the company’s policies & objectives, defines authority, and establishes operational procedures and work instructions to help employees fulfil their job responsibilities. • ISO9001:2000 section 6 emphasises competence, so documents only need be as detailed as required. Documents can take any appropriate form, e.g. written or diagram, and can be in any appropriate media, e.g. paper or intranet. • Note: Not all processes & procedures have to be documented; especially if training, skills & expertise can be relied on. DOCUMENTATION 2 QMS documentation is usually structured like a pyramid, divided into tiers consisting of: Quality Manual … Procedures … Work Instructions … Records … Expectations • Staff must work to documented practice where it exists. • Staff must be aware of Quality Policy & Objectives. • Staff can expect to play a part in ‘quality’ audit. • Staff can expect to be appropriately trained, and be provided with suitable communication channels and appropriate resources. QUALITY CONTROL vs. QUALITY ASSURANCE Quality Control aims to detect nonconformities – it focuses on the end product. Traditionally inspection processes are used at various points in the production of a product or service to control, and assure, quality. Quality Assurance aims to prevent nonconformities – it focuses on the process used to produce the end product. Quality Assurance is all those planned and systematic actions recommended to provide adequate confidence that a product or service will satisfy given requirements for quality. Quality control and inspection are parts of quality assurance. QUALITY ASSURANCE ISO 9000 has always emphasised prevention methods, these avoid the shortcomings of inspection processes and are effective as a quality assurance system due to: • Emphasis shifts from production to quality management. Stress quality rather than quantity. • Causes of problems are addressed. Solve problems at the point that they occur. • Quality responsibility is shared. Responsibility for quality is shared at all levels. • Teamwork is fostered. Personnel through all areas work to find the causes of problems. • The process continually improves. The process is improved as problems are found and fixed. QUALITY AUDITING • A quality audit is a systematic and independent examination to objectively determine whether quality activities and related results comply with planned arrangements and whether these arrangements are implemented effectively and are suitable to achieve their objectives. • Auditing is no more than the establishment of facts; it is not an inquisition, rather it is aimed at helping error reduction / elimination, compliance, verification and communication. • Policies, systems, and procedures may be modified from this information to ensure objectives are achieved, and where possible to improve them. Remember: * It is an audit of the process, not the people carrying it out. * It is not a test! Level 1 – Quality Manual The Quality Manual usually states the company’s quality policy and describes the organization’s quality system. • The quality manual should be brief, concise and not weighted down with details. • Specific “how-to” procedural matters should be located in other supporting documents, such as procedures and work instructions. Level 2 - Procedures A procedure gives information on activities carried out, when & how they are performed and the people that have direct responsibility for them. While the Quality Manual is a company-level document, procedures are an extension of the Quality Manual aimed at different departments. They are activity-based, describing methods and practices used to carry out various quality system activities spanning functional or organization lines. Procedures usually contain: – The purpose and scope of an activity – What is to be done and by whom – When, where and how it will be done – What materials, equipment and documents shall be used – How it shall be controlled and recorded Documented … Level 2 – Procedures 2 Documented procedures do not need to be lengthy, and should be easily understood. The ISO 9000:1994 standard said that a facility need only have documented procedures and work instructions “where the absence on same would adversely affect quality”, and “the range and detail of the procedures that form part of the quality system depend upon the complexity of the work, the methods used, and the skills and training needed by personnel involved in carrying out the activity”. An effective procedure will reduce the amount of training needed for new employees, as responsibilities are clearly defined. Ideally if a procedure is well written, a new competent employee should be able to perform the task simply by following the procedure. Level 3 – Work Instructions Work instructions provide more specific directions for performing an activity listed under a procedure; they are likely to be used either ‘daily’ for critical activities, or less frequently when particular complex activities are carried out. They may, if the order is critical, say step-bystep how to complete a specific task, or they may just tell the operator what steps need to be followed, what equipment and resources are required for a job, what precautionary measures need to be taken, and so forth. • Work instructions contain specifics; but should only exist where necessary, and only be as detailed as required to assure clarity and compliance. • Particularly detailed instructions are most likely the domain of training documents. • Since work instructions are “how to” documents, they are likely to change more frequently than something like the Quality Manual. Level 4 – Records Quality records are documents that furnish objective evidence that a quality requirement has been fulfilled, or demonstrate that the quality system is operating effectively. • Quality records should be easy to read (watch your writing), dated & clean (don’t place your cup on them), and easily identified & retrieved (not in a locked filing cabinet, in a disused toilet, in the basement without a light). See QAP 1.3.