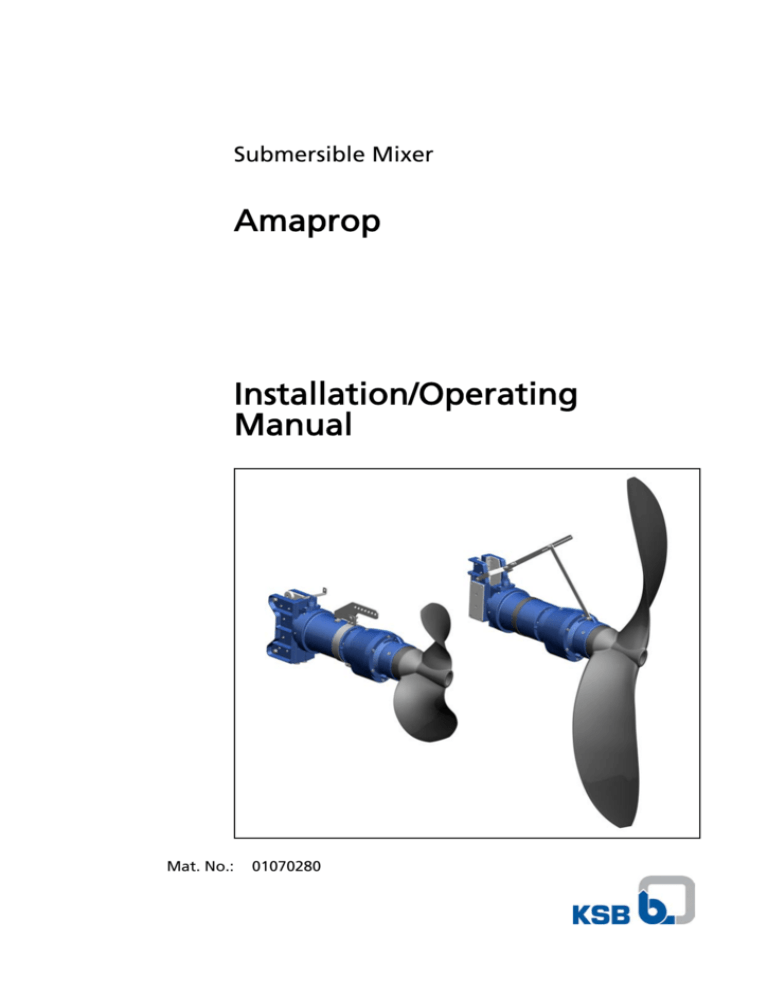

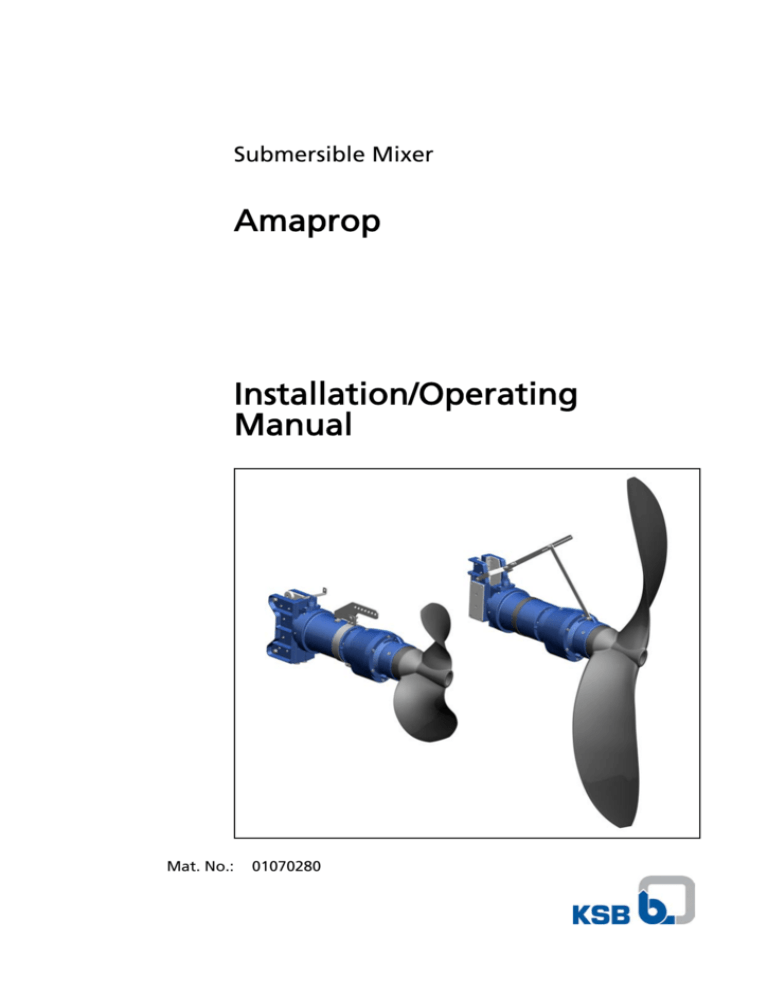

Submersible Mixer

Amaprop

Installation/Operating

Manual

Mat. No.:

01070280

Legal information/Copyright

Installation/Operating Manual Amaprop

Original operating manual

KSB Aktiengesellschaft Halle

All rights reserved. Contents provided herein must neither be distributed, copied, reproduced, edited

or processed for any other purpose, nor otherwise transmitted, published or made available to a third

party without KSB´s express written consent.

Subject to technical modification without prior notice.

© KSB Aktiengesellschaft Frankenthal 12.12.2011

Contents

Contents

Glossary ................................................................................................ 5

1

General ................................................................................................ 6

1.1

Principles .......................................................................................................... 6

1.2

Installation of partly completed machinery .................................................. 6

1.3

Target group ................................................................................................... 6

1.4

Other applicable documents .......................................................................... 6

1.5

Symbols ............................................................................................................ 6

2

Safety ................................................................................................... 7

2.1

Key to safety symbols/markings ..................................................................... 7

2.2

General ............................................................................................................ 7

2.3

Intended use .................................................................................................... 7

2.4

Personnel qualification and training ............................................................. 8

2.5

Consequences and risks caused by non-compliance with these operating

instructions ...................................................................................................... 8

2.6

Safety awareness ............................................................................................. 8

2.7

Safety information for the operator/user ...................................................... 8

2.8

Safety information for maintenance, inspection and installation work ..... 9

2.9

Unauthorised modes of operation ................................................................. 9

2.10

Explosion protection ....................................................................................... 9

3

Transport/Temporary Storage/Disposal ........................................... 10

3.1

Checking the condition upon delivery ......................................................... 10

3.2

Transport ....................................................................................................... 10

3.3

Storage/Preservation ..................................................................................... 11

3.4

Return to supplier ......................................................................................... 11

3.5

Disposal .......................................................................................................... 11

4

Description ......................................................................................... 13

4.1

General description ....................................................................................... 13

4.2

Designation ................................................................................................... 13

4.3

Name plate .................................................................................................... 13

4.4

Design details ................................................................................................ 13

4.5

Configuration and function ......................................................................... 14

4.6

Scope of supply ............................................................................................. 15

4.7

Dimensions and weights ............................................................................... 15

5

Installation at Site ............................................................................. 16

5.1

Safety regulations ......................................................................................... 16

5.2

Checks to be carried out prior to installation ............................................. 16

5.3

Setting the hitching point ............................................................................ 18

5.4

Setting up the submersible mixer ................................................................ 19

Amaprop

3 of 60

Contents

5.5

Electrical system ............................................................................................ 19

5.6

Checking the direction of rotation .............................................................. 25

6

Commissioning/Start-up/Shutdown ................................................. 26

6.1

Commissioning/start-up ................................................................................ 26

6.2

Operating limits ............................................................................................ 26

6.3

Shutdown/storage/preservation ................................................................... 30

6.4

Returning to service ...................................................................................... 31

7

Servicing/Maintenance ...................................................................... 32

7.1

Safety regulations ......................................................................................... 32

7.2

Servicing/inspection ...................................................................................... 33

7.3

Drainage/disposal .......................................................................................... 40

7.4

Dismantling the submersible mixer ............................................................. 40

7.5

Reassembling the submersible mixer ........................................................... 43

7.6

Tightening torques ....................................................................................... 46

7.7

Spare parts stock ........................................................................................... 46

8

Trouble-shooting ............................................................................... 48

9

Related Documents ........................................................................... 49

9.1

General assembly drawing with list of components ................................... 49

9.2

Flamepaths on explosion-proof motors ....................................................... 52

9.3

Wiring diagrams ............................................................................................ 53

9.4

Forcing screws ............................................................................................... 55

10

EC Declaration of Conformity .......................................................... 56

11

Certificate of decontamination ........................................................ 57

Index .................................................................................................. 58

4 of 60

Amaprop

Glossary

Glossary

Certificate of decontamination

A certificate of decontamination certifies that

the submersible mixer has been properly

cleaned and decontaminated to eliminate any

environmental and health hazards arising from

components in contact with the fluid handled.

fluid the mixer is operated in, i.e. generally

municipal or industrial waste water and

sludges. The fluid is described in greater detail

by means of the gas and solids content, the

content and length of fibrous substances, its

chemical composition and temperature.

Submersible mixer

Fluid

In accordance with the intended use of the

submersible mixer, the term "fluid" (also

referred to as the fluid handled) refers to the

Amaprop

Submersible mixers are mixing units with open

axial propeller hydraulics and a dry submersible

motor.

5 of 60

1 General

1 General

1.1 Principles

This manual is supplied as an integral part of the type series and variants indicated

on the front cover. It describes the proper and safe use of this equipment in all

phases of operation.

The name plate indicates the type series and size, the main operating data, the order

number and the order item number. The order number and order item number

clearly identify the submersible mixer and serve as identification for all further

business processes.

In the event of damage, contact your nearest KSB service centre immediately to

maintain the right to claim under warranty.

1.2 Installation of partly completed machinery

To install partly completed machinery supplied by KSB, refer to the sub-sections

under Servicing/Maintenance.

1.3 Target group

This operating manual is aimed at the target group of trained and qualified specialist

technical personnel.

1.4 Other applicable documents

Table 1: Overview of applicable documents

Document

Data sheet

General arrangement drawing/

dimension sheet

General drawing1)

Supplier documentation1)

Spare parts lists1)

List of components1)

Content

Description of technical data

Description of connection and arrangement

dimensions

Description in sectional representation

Operating manuals and other documentation for

accessories and integrated machine parts

Description of spare parts

Description of components

1.5 Symbols

Table 2: Symbols used in this manual

Symbol

✓

⊳

⇨

⇨

1.

Description

Conditions which need to be fulfilled before proceeding with the

step-by-step instructions

Safety instructions

Result of an action

Cross-references

Step-by-step instructions

2.

Note

Recommendations and important information on how to handle

the product

1)

if agreed upon in scope of supply

6 of 60

Amaprop

2 Safety

2 Safety

!

DANGER

All the information contained in this section refers to hazardous situations.

2.1 Key to safety symbols/markings

Table 3: Definition of safety symbols/markings

Symbol

!

DANGER

!

WARNING

CAUTION

Description

DANGER

This signal word indicates a high-risk hazard which, if not avoided,

will result in death or serious injury.

WARNING

This signal word indicates a medium-risk hazard which, if not

avoided, could result in death or serious injury.

CAUTION

This signal word indicates a hazard which, if not avoided, could

result in damage to the machine and its functions.

Explosion protection

This symbol identifies information about avoiding explosions in

potentially explosive atmospheres in accordance with EC Directive

94/9/EC (ATEX).

General hazard

In conjunction with one of the signal words this symbol indicates a

hazard which will or could result in death or serious injury.

Electrical hazard

In conjunction with one of the signal words this symbol indicates a

hazard involving electrical voltage and identifies information

about protection against electrical voltage.

Machine damage

In conjunction with the signal word CAUTION this symbol indicates

a hazard for the machine and its functions.

2.2 General

This manual contains general installation, operating and maintenance instructions

that must be observed to ensure safe operation of the submersible mixer and prevent

personal injury and damage to property.

The safety information in all sections of this manual must be complied with.

This manual must be read and completely understood by the responsible specialist

personnel/operators prior to installation and commissioning.

The contents of this manual must be available to the specialist personnel at the site

at all times.

Information attached directly to the submersible mixer must always be complied

with. This applies to, for example:

▪ Arrow indicating the direction of rotation

▪ Markings for connections

▪ Name plate

The operator is responsible for ensuring compliance with all local regulations which

are not taken into account in this manual.

2.3 Intended use

The submersible mixer must only be operated within the operating limits described in

the other applicable documents.

▪ Only operate submersible mixers which are in perfect technical condition.

▪ Do not operate partially assembled submersible mixers.

Amaprop

7 of 60

2 Safety

▪ Only use the submersible mixer in the fluid described in the data sheet or

product literature.

▪ Never operate the submersible mixer without fluid.

▪ Observe the minimum fluid levels indicated in the data sheet or product

literature (to prevent overheating, bearing damage, cavitation damage, etc.).

▪ Consult the manufacturer about any use or mode of operation not described in

the data sheet or product literature.

▪ Never exceed the permissible operating limits (temperature, etc.) specified in the

data sheet or product literature.

▪ Observe all safety information and instructions in this manual.

2.4 Personnel qualification and training

All personnel involved must be fully qualified to install, operate, maintain and

inspect the machinery this manual refers to.

The responsibilities, competence and supervision of all personnel involved in

installation, operation, maintenance and inspection must be clearly defined by the

operator.

Deficits in knowledge must be rectified by sufficiently trained specialist personnel

training and instructing the personnel who will carry out the respective tasks. If

required, the operator can commission the manufacturer/supplier to train the

personnel.

Training on the submersible mixer must always be supervised by technical specialist

personnel.

2.5 Consequences and risks caused by non-compliance with these operating

instructions

▪ Non-compliance with these operating instructions will lead to forfeiture of

warranty cover and of any and all rights to claims for damages.

▪ Non-compliance can, for example, have the following consequences:

– Hazards to persons due to electrical, thermal, mechanical and chemical

effects and explosions

– Failure of important product functions

– Failure of prescribed maintenance and servicing practices

– Hazard to the environment due to hazardous substances

2.6 Safety awareness

In addition to the safety information contained in this manual and the intended use,

the following safety regulations shall be complied with:

▪ Accident prevention, health and safety regulations

▪ Explosion protection regulations

▪ Safety regulations for handling hazardous substances

▪ Applicable standards and laws

2.7 Safety information for the operator/user

▪ Provide the personnel with protective equipment and make sure it is used.

▪ Contain leakages so as to avoid any danger to persons and the environment.

Adhere to all relevant laws.

▪ Eliminate all electrical hazards. (In this respect refer to the applicable national

safety regulations and/or regulations issued by the local energy supply

companies.)

8 of 60

Amaprop

2 Safety

▪ Take suitable precautions to prevent persons from coming near the propeller

when the submersible mixer is running.

▪ It is strictly prohibited for any person to enter the tank while the submersible

mixer is running.

2.8 Safety information for maintenance, inspection and installation work

▪ Modifications or alterations of the submersible mixer are only permitted with the

manufacturer's prior consent.

▪ Use only original spare parts or parts authorised by the manufacturer. The use of

other parts can invalidate any liability of the manufacturer for resulting damage.

▪ The operator ensures that all maintenance, inspection and installation work is

performed by authorised, qualified specialist personnel who are thoroughly

familiar with the manual.

▪ Carry out work on the submersible mixer during standstill only.

▪ The submersible mixer must have cooled down to ambient temperature.

▪ When taking the mixer out of service always adhere to the procedure described

in the manual.

▪ Decontaminate submersible mixers used in fluids posing a health hazard.

▪ As soon as the work is completed, re-install and/or re-activate any safety-relevant

and protective devices. Before returning the product to service, observe all

instructions on commissioning.

2.9 Unauthorised modes of operation

Never operate the submersible mixer outside the limits stated in the data sheet and

in this manual.

The warranty relating to the operating reliability and safety of the submersible mixer

supplied is only valid if the mixer is used in accordance with its intended use.

2.10 Explosion protection

!

DANGER

Always observe the information on explosion protection given in this section when

operating the submersible mixer in potentially explosive atmospheres.

Sections of the manual marked by the Ex symbol apply to explosion-proof

submersible mixers also when temporarily operated outside of potentially explosive

atmospheres.

Only submersible mixers marked as explosion-proof and identified as such in the data

sheet must be used in potentially explosive atmospheres.

Special conditions apply to the operation of explosion-proof submersible mixers to EC

Directive 94/9/EC (ATEX).

When operating explosion-proof mixers, especially adhere to the additional

requirements marked by the Ex symbol.

The explosion-proof status of the submersible mixer is only assured if the submersible

mixer is used in accordance with its intended use.

Never operate the submersible mixer outside the limits stated in the data sheet and

on the name plate.

Prevent impermissible modes of operation at all times.

Correct monitoring of the winding temperature is imperative.

2.10.1 Repair

Special regulations apply to repair work on explosion-proof submersible mixers.

Modifications or alterations of the submersible mixer may affect explosion protection

and are only permitted after consultation with the manufacturer.

Repair work at the flameproof joints must only be performed in accordance with the

manufacturer's instructions. Repair to the values in tables 1 and 2 of EN 60079-1 is

not permitted.

Amaprop

9 of 60

3 Transport/Temporary Storage/Disposal

3 Transport/Temporary Storage/Disposal

3.1 Checking the condition upon delivery

1. On transfer of goods, check each packaging unit for damage.

2. In the event of in-transit damage, assess the exact damage, document it and

notify KSB or the supplying dealer (as applicable) and the insurer about the

damage in writing immediately.

3.2 Transport

DANGER

Improper transport

Risk of danger to life due to falling parts!

Risk of damage to submersible mixer!

▷ Use the provided hitching point on the lifting bail to attach a load-carrying

device.

▷ Never suspend the submersible mixer on the electrical connection line.

▷ Never use chains or lifting ropes from the scope of supply as a general loadcarrying device.

▷ Suspend lifting ropes or chains securely to the submersible mixer and to the

crane.

Transport the submersible mixer as shown.

Fig. 1: Transporting the submersible mixer

10 of 60

Amaprop

3 Transport/Temporary Storage/Disposal

3.3 Storage/Preservation

If commissioning is to take place some time after delivery, we recommend that the

following measures be taken for storage:

CAUTION

Improper storage

Damage to the power cables!

▷ Support the power cables at the cable entry to prevent permanent deformation.

▷ Only remove the protective caps from the power cables at the time of

installation.

CAUTION

Damage during storage by humidity, dirt or vermin

Corrosion/contamination of the submersible mixer!

▷ For outdoor storage cover the (packed or unpacked) submersible mixer and

accessories with waterproof material.

▪ Store the submersible mixer under dry and vibration-free conditions, if possible

in its original packaging.

Table 4: Ambient conditions for storage

Ambient conditions

Relative humidity

Value

5 % to 85 %

Ambient temperature

(non-condensing)

- 20 ℃ to + 70°C

3.4 Return to supplier

1. Always flush and clean the submersible mixer, particularly if it has been used in

noxious, explosive, hot or other hazardous fluids.

2. If the submersible mixer has been used in fluids leaving residues which might

lead to corrosion when coming into contact with atmospheric humidity, or which

might ignite when coming into contact with oxygen, the submersible mixer must

also be neutralised and treated with anhydrous inert gas for drying purposes.

3. Always complete and enclose a certificate of decontamination when returning

the submersible mixer.

Always indicate any safety and decontamination measures taken.

NOTE

If required, a blank certificate of decontamination can be downloaded from the KSB web

site at: www.ksb.com/certificate_of_decontamination

3.5 Disposal

WARNING

Fluids posing a health hazard

Hazard to persons and the environment!

▷ Submersible mixers used in fluids posing a health hazard must be

decontaminated.

▷ Collect and properly dispose of flushing liquid and any liquid residues.

▷ Wear safety clothing and a protective mask, if required.

▷ Observe all legal regulations on the disposal of harmful substances.

1. Dismantle the submersible mixer.

Collect greases and lubricating liquids during dismantling.

Amaprop

11 of 60

3 Transport/Temporary Storage/Disposal

2. Separate and sort the materials, e.g. by:

- Metals

- Plastics

- Electronic waste

- Greases and lubricating liquids

3. Dispose of materials in acc. with local regulations or in another controlled

manner.

12 of 60

Amaprop

4 Description

4 Description

4.1 General description

▪ Submersible mixer

Submersible mixer with self-cleaning propeller to treat communal or industrial waste

water and sludge as well as for use in biogas systems.

4.2 Designation

Example: Amaprop V 46-2500/5 4 UR G

Table 5: Explanation of designation

Abbreviation

Amaprop

V

46

2500

5

4

UR

G

Meaning

Production series

Propeller material e.g.: V = composite material

Nominal speed of propeller

Size/nominal diameter of propeller e.g.: 2500 mm

Motor size

Number of contacts on motor

Motor variant e.g. UR = standard version

Casing material e.g. G = gray cast iron

4.3 Name plate

b)

a)

1

2

3

4

5

6

7

8

9

KSB Aktiengesellschaft

67227 Frankenthal

KSB Aktiengesellschaft

67227 Frankenthal

TYPE AMAPROP V 46 - 2500 / 54 URG

9971511000/000310

No.

2010

H

Q

231 kg

TEMP. MAX. 40 °C

Motor IP 68 SUBM. MAX. 30 m CLASS F

DKM 112 M4

3~ M.-No. 242823

400/690 V

P2 6,5

kW

50 Hz cos φ 0,87

1445 min-1 12,7 / 7,4 A IA/IN 6,0

S1

WARNUNG - NICHT UNTER SPANNUNG ÖFFNEN

WANING - DO NOT OPEN WHEN ENERGIZED

AVERTISSEMENT - NE PAS OUVRIR SOUS TENSION

Mat. No: 01080556

TYPE AMAPROP V 46 - 2500 / 54 YRG

9971511000/000310

No.

II2G Ex dc IIB T4

2010

H

Q

231 kg

TEMP. MAX. 40 °C

Motor IP 68 SUBM. MAX. 30 m CLASS F

DKM 112 M4

3~ M.-No. 242823

400/690 V

P2 6,5

kW

50 Hz cos φ 0,87

1445 min-1 12,7 / 7,4 A IA/IN 6,0

S1

10

11

12

13

14

15

16

17

18

19

ZN 3826 - M 12

0035

20

II2G Ex d IIB T4 PTB 02 ATEX 1055

WARNUNG - NICHT UNTER SPANNUNG ÖFFNEN

WANING - DO NOT OPEN WHEN ENERGIZED

AVERTISSEMENT - NE PAS OUVRIR SOUS TENSION

Mat. No: 01080566

ZN 3826 - M 16

Fig. 2: Name plate (example) a) standard submersible mixer, b) explosion-protected submersible mixer

1

3

5

7

9

11

13

15

17

19

Designation

Maximum medium and ambient temperature

Motor type

Rated speed

Rated current

Total weight

Thermal class of winding insulation

Power factor at measurement point

Operating mode

Atex marking for the submersible motor

2

4

6

8

10

12

14

16

18

20

KSB order and order item number

Type of protection

Rated power

Rated voltage

Year of construction

Maximum submersion depth

Motor number

Rated frequency

Starting current ratio

Marking for a submersible mixer with explosion

protection

4.4 Design details

Construction

▪ Fully floodable submersible mixer

Amaprop

13 of 60

4 Description

▪ Horizontal installation

Propeller form

▪ Self-cleaning (ECB) propeller

Shaft seal

▪ Two bi-directional mechanical seals in tandem arrangement, with liquid reservoir

▪ Additional leakage chamber between the mating ring holder and the gear unit

Bearing

▪ Rolling element bearing lubricated with life-long grease in motor

▪ Oil-lubricated rolling element bearing in transmission

Drive

▪ Three-phase asynchronous squirrel-cage motor

Explosion-protected submersible mixers have integrated motors of protection type Ex

d IIB.

4.5 Configuration and function

1

5

2

6

3

7

4

8

Fig. 3: Sectional drawing

1

3

5

7

14 of 60

Gear shaft

Stator

Propeller

Rolling element bearing

Amaprop

2

4

6

8

Housing

Cable gland

Mechanical seal

Rotor

4 Description

Design

Function

Sealing

Submersible mixer with gear unit and self-cleaning propeller (5) for mixing and

keeping in suspension municipal or industrial waste water and sludges.

Driven by the motor, the propeller (5) generates thrust for inducing the required

flow in the fluid handled.

The gear shaft (1) of the submersible mixer is equipped with two bi-rotational

mechanical seals (6) in tandem arrangement. A lubricant reservoir between the two

mechanical seals ensures cooling and lubrication.

The cable gland (4) is totally watertight.

4.6 Scope of supply

Depending on the model, the following items are included in the scope of supply:

▪ Submersible mixer complete with lifting bail or support lugs and electrical

connection line

▪ Cable holder for electrical connection line

▪ Two shackles (for fastening device and cable holder)

▪ Separate name plate

NOTE

There is a separate name plate in the scope of supply.

Attach this plate in a position where it is easily visible, outside of the place of installation

e.g. on the switch cabinet or on the console.

Accessories

▪ Submersible mixer stand

▪ Cable holder for proper routing of electrical connection lines in tank

▪ Forcing screw

▪ Additional accessories on request

4.7 Dimensions and weights

For dimensions and weights please refer to the general arrangement drawing/outline

drawing and data sheet of the submersible mixer.

Amaprop

15 of 60

5 Installation at Site

5 Installation at Site

5.1 Safety regulations

DANGER

Improper installation in potentially explosive atmospheres

Explosion hazard!

Damage to the submersible mixer!

▷ Comply with the applicable local explosion protection regulations.

▷ Observe the information given in the data sheet and on the name plate.

DANGER

Persons entering the tank

Electric shock!

▷ Never start up the submersible mixer when there are persons inside the tank.

▷ Disconnect or electrically disable the submersible mixer before entering the

tank.

WARNING

Hands, other body parts, or foreign objects in the propeller or propeller intake area

Risk of personal injury! Damage to the submersible mixer!

▷ Never place your hands, other body parts or foreign objects into the propeller

or propeller intake area.

5.2 Checks to be carried out prior to installation

5.2.1 Checking the operating data

Before setting up the submersible mixer, verify that the name plate data matches the

data given in the purchase order and the system data.

5.2.2 Preparing the place of installation

WARNING

Setup on unsurfaced and non-load-bearing setup area

Danger of personal injury or property damage!

▷ Observe sufficient compressive strength as per class C25/30 of cement in the

exposure class XC1 as per EN 206-1.

▷ Setup area must be hardened, level and horizontal.

▷ Observe weight specifications.

NOTE

A visual option must be provided for operation in biogas systems )e. g.: viewing window)

to check and possibly adjust the conditions of the submersible mixer.

NOTE

For servicing submersible mixers in biogas installations, access openings and

appropriate means of removal (lifting gear) must be provided so that the mixer can be

removed from the filled tank at any time. For this purpose, it is important to observe the

minimum removal dimensions for the submersible mixer as specified in the general

arrangement drawing/outline drawing and in the data sheet.

1. Check structural work.

16 of 60

Amaprop

5 Installation at Site

⇨ Structural work must be prepared as per dimensions of dimension sheet/

general arrangement drawing.

5.2.3 Checking the lubricant level

A

B

903.01

411.01

Fig. 4: Check lubricant — illustration without propeller

A Lubricant checking screw (transmission)

B Lubricant filler screw (transmission)

The lubricant reservoirs have been filled with an environmentally-friendly, non-toxic

lubricant at the factory.

Lubricant level for

mechanical seal

1. Position the submersible mixer as shown.

2. Unscrew screw plug 903.01 and joint ring 411.01.

⇨ The lubricant level must be at the height of the filler opening.

3. If the lubricant level is lower, fill the lubricant chamber up to above the filler

opening, until it overflows.

4. Screw in screw plug 903.01 and joint ring 411.01.

Amaprop

17 of 60

5 Installation at Site

Lubricant level for

transmission

1. Unscrew the transmission lubricant checking screw.

⇨ The lubricant level must be at the height of the filler opening.

2. If the lubricant level is lower, unscrew the transmission lubricant level filler screw

and fill the lubricant chamber up to above the lubricant filler opening until an

overflow occurs from the lubricant control opening.

3. Screw in the transmission lubricant checking screw and lubricant level filler screw

if necessary.

5.3 Setting the hitching point

The correct hitching point must be set in order to ensure reliable installation and

problem-free lifting and lowering of the submersible mixer on the submersible mixer

stand.

Amaprop 1000

a)

b)

1

1

2

3

2

3

Fig. 5: Setting the hitching point, Amaprop 1000 — a) GFK propeller b) cast iron

propeller

1

3

Hitching point

Support clamp

2

Support lug

To ensure problem-free lifting and lowering, there must be a slight slant when

suspending on the support lug (propeller facing downward). If there is a deviating

angle, the hitching point must be corrected.

Correcting the hitching point:

The support clamp is mounted at the factory as shown and the position must not be

changed!

The correct hitching point is set by selecting the correct hole in the support lug.

▪ GFK propeller (~ 35 kg): First hole of support lug counted from the guide pipe

▪ Cast iron propeller (~92 kg): Fourth hole (centre hole) of support lug counted

from the guide pipe

Amaprop 1200–2500

Fig. 6: Slant approx. 5°

18 of 60

Amaprop

5 Installation at Site

To ensure problem-free lifting and lowering, there must be a slant of approx 5° when

suspending on the lifting bail (propeller facing upwards). If there is a deviating

angle, the hitching point must be corrected.

Correcting the hitching point:

1. Slightly loosen bolts 901.03 on bracket 732 and bolt 901.04 on mating ring holder

476.

2. Loosen upper screw connection on lifting bail.

3. Select a hole on the hole bar as per the existing slant angle positioning.

CAUTION

Loose or insufficiently tight screw connections

Damage to setup parts during operation

▷ Note bolt tightening torques.

4. Tighten all bolts again. (⇨ Section 7.6 Page 46)

5. Perform hitching procedure again.

⇨ If there is an angle of approx. 5°, the correct centre of gravity has been found.

5.4 Setting up the submersible mixer

CAUTION

Incorrect installation position of submersible mixer

Damage by excessive stresses or strains!

▷ Observe the data given in the general arrangement drawing.

▷ Installation in other positions is only permitted after prior consultation with and

approval by KSB.

Mount the submersible mixer onto each submersible mixer stand as described in the

separate operating/assembly instructions for "submersible mixer stand".

5.5 Electrical system

5.5.1 Information for planning the control system

Follow the "Electrical wiring diagrams" in the appendix for the electrically

connecting the submersible mixer. (⇨ Section 9.3 Page 53)

The submersible mixer is delivered with electrical connection line and is intended for

direct start. For motors 4 4, 5 4, 6 4, 11 4, 16 4 and 23 4, a star-triangle start is also

possible.

NOTE

When laying a cable between the control system and the submersible mixer's connection

point, make sure to have a sufficient number of cores for the sensors! A minimum cable

cross-section of 1.5 mm² is required.

The motors can be connected to electrical low voltage networks with nominal

voltages and voltage tolerances as per IEC 38 or other networks or supply systems

with rated voltage tolerances of max. ±10 %.

5.5.1.1 Overload protection

1. Protect the submersible mixer against overloading by a thermal time-lag

overload protection device in accordance with IEC 947 and local regulations.

2. Set the overload protection device to the rated current specified on the name

plate. (⇨ Section 4.3 Page 13)

Amaprop

19 of 60

5 Installation at Site

5.5.1.2 Level switch

DANGER

Dry-running of submersible mixer

Explosion hazard!

▷ Never allow an explosion-proof submersible mixer to run dry!

CAUTION

Propeller not fully submerged

Damage to the submersible mixer!

▷ Never allow the liquid level to drop below the submersible mixer during mixer

operation (not even for short periods).

Automatic mixer operation in a tank requires the use of level control equipment.

Observe the specified minimum fluid level. (⇨ Section 6.2.2.1 Page 27)

5.5.1.3 Frequency inverter operation

The submersible mixer is suitable for frequency inverter operation as per IEC

60034-17.

NOTE

For use in biogas systems, an Amaprop 1000 can be operated at 50 Hz mains power.

When using an Amaprop 2500 in biogas systems, operation with a frequency converter

is required.

DANGER

Operation outside the permitted frequency range

Explosion hazard!

▷ Never operate an explosion-proof submersible mixer outside the specified

range.

DANGER

Incorrect setting of frequency inverter current limit

Explosion hazard!

▷ Set the current limit to max. 1.2 times the rated current indicated on the name

plate.

Selection

When selecting the frequency inverter, check the following details:

▪ Data provided by the manufacturer

▪ Electrical data of the submersible mixer, particularly the rated current

Operation

Observe the following limits when operating the submersible mixer via frequency

inverter:

▪ Only utilise up to 95 % of the motor power rating P2 indicated on the name

plate. (⇨ Section 4.3 Page 13)

▪ Frequency range 25-50 Hz

Electromagnetic

compatibility

If the mixers are operated via frequency inverter, RFI emissions will occur, the level of

which varies depending on the inverter used (inverter type, interference suppression

features, manufacturer). To ensure compliance of the drive system consisting of

submersible motor and frequency inverter with the limits stipulated by EN 50081,

always observe the EMC information provided by the inverter manufacturer. If the

manufacturer recommends shielded power cables, a submersible mixer with shielded

power cable must be used.

The submersible mixers generally meet the requirements on interference immunity

stipulated by EN 50082. For monitoring the sensors installed, the operator must

ensure sufficient interference immunity by selecting and routing the cable in the

20 of 60

Amaprop

5 Installation at Site

plant accordingly. No modifications are required on the power cable of the

submersible mixer itself. Suitable analysing devices must be selected. In this case we

recommend to monitor the leakage sensor fitted inside the motor by means of a

special relay available from KSB.

5.5.1.4 Sensors

DANGER

Operating an incompletely connected submersible mixer

Explosion hazard!

▷ Never start up a submersible mixer with incompletely connected power cables

or non-operational monitoring devices.

The submersible mixer is equipped with sensors designed to prevent hazards and

damage to the mixer.

Measuring transducers are required for analysing the sensor signals supplied. Suitable

devices for 230V~ can be supplied by KSB.

NOTE

Reliable and safe operation of the submersible mixer within the scope of our warranty is

only possible if the sensor signals are properly analysed as stipulated in the manual.

All sensors are located inside the submersible mixer and are connected to the power

cable.

For information on wiring and core identification please refer to the wiring

diagrams. (⇨ Section 9.3 Page 53)

The individual sensors and the limit values to be set are described in the following

sections.

5.5.1.4.1 Motor temperature

DANGER

Insufficient cooling conditions

Risk of explosion!

▷ Never operate an explosion-protected submersible mixer without efficient

temperature monitoring.

▷ For explosion-protected submersible mixers, use a thermistor tripping unit with

restart lockout and ATEX approval for temperature monitoring of explosionprotected motors of protection type "pressure-resistant enclosure" Ex d.

CAUTION

Insufficient cooling

Damage to the submersible mixer!

▷ Never operate a submersible mixer without operational temperature

monitoring equipment.

The motor is monitored by three series-connected PTC thermistors with terminals 10

and 11. They must be connected to a thermistor tripping unit with manual reset.

Tripping must result in the submersible mixer cutting out.

For explosion-proof submersible mixers use a thermistor tripping unit which is ATEXapproved for monitoring the temperature of explosion-proof motors in "flameproof

enclosure" Ex d type of protection.

Amaprop

21 of 60

5 Installation at Site

5.5.1.4.2 Leakage inside the motor

DANGER

Incorrect monitoring of leakage electrodes

Risk of explosion!

▷ Only use voltages under 30 V and tripping currents under 0.5 mA.

b)

a)

K1

9

PE

B2

B2

Fig. 7: a) Connecting electrode relay and b) position of electrode in casing

There is an electrode (B2) inside the motor for leakage monitoring of the winding

and connection compartments. The electrode is intended for connection to an

electrode relay (conductor marking 9). If the electrode relay is triggered, this must

shutdown the submersible mixer.

The electrode relay (K1) must fulfil the following requirements:

▪ Sensor circuit 10 to 30 V ~

▪ Tripping current 0.5 to 3 mA

(corresponds to a tripping resistance of 3 to 60 kΩ)

5.5.1.4.3 Leakage at the mechanical seal (optional)

DANGER

Incorrect connection

Risk of explosion!

▷ Never retrofit an explosion-protected submersible mixer with such leakage

chamber monitoring.

22 of 60

Amaprop

5 Installation at Site

b)

a)

K1

6

7

bl

br

B5

B2

Fig. 8: a) Connecting electrode relay and b) position of leakage monitor

The submersible mixer has a leakage chamber between the oil chamber and the

transmission. This can be equipped with leakage monitoring. A leakage monitor

detects when the leakage chamber is filled due to defective mechanical seals. The

leakage monitor has a separate connection line and is intended for connection to an

electrode relay. If the electrode relay is triggered, this must shutdown the

submersible mixer.

The electrode relay (K1) must fulfil the following requirements:

▪ Sensor circuit 10 to 30 V ~

▪ Tripping current 0.5 to 3 mA

(corresponds to a tripping resistance of 3 to 60 kΩ)

5.5.2 Connection to power supply

DANGER

Electrical connection work by unqualified personnel

Danger of death from electric shock!

▷ Always have the electrical connections installed by a trained electrician.

▷ Observe regulations IEC 30364 (DIN VDE 0100) and, for explosion-proof models,

IEC 60079 (DIN VDE 0164).

WARNING

Incorrect connection to the mains

Damage to the mains network, short circuit!

▷ Observe the technical specifications of the local energy supply companies.

CAUTION

Improper routing of power cable

Damage to the power cable!

▷ Never move the power cable at temperatures below - 25 °C.

▷ Never kink or crush the power cable.

▷ Never suspend the submersible mixer by its power cable.

CAUTION

Motor overload

Damage to the motor!

▷ Protect the motor by a thermal time-lag overload protection device in

accordance with IEC 947 and local regulations.

Amaprop

23 of 60

5 Installation at Site

When carrying out the electrical connection, observe the electrical wiring diagrams

and instructions for planning the switch system. (⇨ Section 9.3 Page 53) (⇨ Section

5.5.1 Page 19)

The submersible mixer is delivered with an electrical connection line. Always connect

all marked conductors.

DANGER

Operating an incompletely connected submersible mixer

Explosion hazard!

▷ Never start up a submersible mixer with incompletely connected power cables

or non-operational monitoring devices.

DANGER

Incorrect connection

Explosion hazard!

▷ The connection point of the cable ends must be located outside the potentially

explosive atmosphere or inside electrical equipment approved to equipment

category II2G.

CAUTION

Flow-induced motion and layers of floating sludge in biogas installations

Damage to the power cable!

▷ Run the power cable upwards with as little slack as possible and protect, if

necessary.

NOTE

We recommend to use cable supports available as accessories for properly fastening the

electrical cable at the tank edge.

1. Guide electrical connection line pointing upwards and secure.

2. Remove protective caps on the electrical connection line just before connection.

3. If necessary, adjust the length of the electrical connection line in accordance with

local conditions.

4. After shortening the line, correctly re-attach the appropriate markings to the

individual conductors of the line end.

Potential equalisation

The submersible mixer does not have an external potential equalisation connection

(risk of corrosion).

DANGER

Incorrect wiring

Explosion hazard!

▷ Explosion-proof submersible mixers installed in a tank must never be retrofitted

with an external potential equalisation connection!

DANGER

Touching the submersible mixer during operation

Electric shock!

▷ Make sure that the submersible mixer cannot be touched during operation.

24 of 60

Amaprop

5 Installation at Site

5.6 Checking the direction of rotation

WARNING

Hands, other body parts, or foreign objects in the propeller or propeller intake area

Risk of personal injury! Damage to the submersible mixer!

▷ Never place your hands, other body parts or foreign objects into the propeller

or propeller intake area.

CAUTION

Incorrect direction of rotation

Risk of damage to submersible mixer and submersible mixer stand!

▷ Check direction of rotation.

▷ Follow direction of rotation arrow.

▷ Allow the submersible mixer to run as briefly as possible during the direction of

rotation test. (Maximum of one minute)

CAUTION

Propeller not fully submerged

Damage to the submersible mixer!

▷ Never lower the submersible mixer into the fluid while checking the direction of

rotation.

✓ The submersible mixer is mounted on the submersible mixer stand and is located

completely outside the medium.

✓ The submersible mixer is electrically connected.

1. Allow to run briefly by switching the submersible mixer quickly on and off and

observe the direction of rotation.

2. Check the direction of rotation.

The propeller must move clockwise

(see direction of rotation arrow on casing).

Fig. 9: Check direction of

rotation

Fig. 10: Direction of rotation arrow

3. If the direction of rotation is incorrect, check the connection of the submersible

mixer and the switch system if necessary.

4. Lower submersible mixer to its operating position.

Amaprop

25 of 60

6 Commissioning/Start-up/Shutdown

6 Commissioning/Start-up/Shutdown

6.1 Commissioning/start-up

6.1.1 Prerequisites for commissioning/start-up

Before commissioning, the following conditions must be ensured:

▪ The submersible mixer is correctly mounted to the submersible mixer stand.

▪ The submersible mixer is electrically connected to all protection devices in

accordance with regulations.

▪ Operating data, lubricant level and direction of rotation have been checked.

6.1.2 Start-up

DANGER

Excessive temperatures due to dry running or excessive fluid temperature

Explosion hazard!

▷ Never operate the submersible mixer outside the fluid.

▷ Observe the minimum level of the fluid handled.

▷ Never operate an explosion-proof submersible mixer at ambient and fluid

temperatures exceeding those specified in the data sheet or on the name plate.

▷ Always operate the submersible mixer within the permissible operating range

only.

CAUTION

Excessive temperatures due to dry running or excessive fluid temperature

Damage to the submersible mixer!

▷ Never operate the submersible mixer outside the fluid.

▷ Observe the minimum level of the fluid handled.

▷ Always operate the submersible mixer within the permissible operating range

only.

CAUTION

Re-starting while motor is still running down

Damage to the submersible mixer!

▷ Do not re-start the submersible mixer before it has come to a standstill.

▷ Never start up a submersible mixer running in reverse rotation.

1. Start up the submersible mixer.

6.2 Operating limits

DANGER

Non-compliance with operating limits

Damage to the submersible mixer!

▷ Comply with the operating data indicated in the data sheet.

▷ Never operate an explosion-proof submersible mixer at ambient and fluid

temperatures exceeding those specified in the data sheet or on the name plate.

26 of 60

Amaprop

6 Commissioning/Start-up/Shutdown

6.2.1 Frequency of starts

CAUTION

Excessive switching frequency

Risk of damage to the motor!

▷ Never exceed the specified switching frequency.

CAUTION

Re-starting while motor is still running down

Damage to the submersible mixer!

▷ Do not re-start the submersible mixer before it has come to a standstill.

▷ Never start up a submersible mixer running in reverse rotation.

To avoid a severe increase in temperature in the motor and excessive loads on the

motor, seals and bearings, the number of switching operations should not exceed 10

per hour and 5000 per year.

These values apply for switching on the mains (directly or with star-triangle

protection, starting transformer, smooth start device). This limitation does not apply

to operation on a frequency converter.

6.2.2 Fluid properties

CAUTION

Layers of floating sludge in biogas plants

Damage to the submersible mixer!

▷ Never use the submersible mixer Amaprop 2500 for breaking up layers of

floating sludge in biogas plants.

NOTE

Deposits accumulating on the housing surface entail the risk of insufficient cooling of the

submersible mixer. We recommend to check the housing surface regularly and remove

severe dirt deposits.

6.2.2.1 Minimum level of fluid handled

DANGER

Excessive temperatures due to dry-running

Explosion hazard!

▷ Always operate the submersible mixer in fully submerged condition only (incl.

propeller).

▷ Observe the minimum level of the fluid handled.

CAUTION

Propeller not fully submerged

Damage to the submersible mixer!

▷ Never allow the liquid level to drop below the submersible mixer during mixer

operation (not even for short periods).

The submersible mixer is operational when the fluid level is not lower than

dimension WT. This minimum level of the fluid handled must also be ensured during

automatic operation.

Amaprop

27 of 60

W

h1

ØD

T

h

2

6 Commissioning/Start-up/Shutdown

Fig. 11: Minimum level of fluid handled

Table 6: Minimum level of fluid handled

ØD

[mm]

All

Formula for calculating

the minimum fluid level

h2 = (nMixer / nmax)² x h2*

h2* for sewage treatment plants/water = 1.00 m (0.75 m for Amaprop 1000)

h2* for biogas applications / digestion substrate = 0.50 m

Wt = Ø D + h1 + h2

Calculation example

Given:

▪ Amaprop V 40-2500/44

▪ Biogas application - digestion substrate

▪ nMixer = 40 rotations/minute

▪ nmax = 46 rotations/minute

Solution:

h2 = (40 / 46)² x 0.50 m = 0.38 m

Wt = 2.50 m + 0.30 m + 0.38 m = 3.18 m

2)

3)

Minimum

For biogas applications: 0.30 m

28 of 60

h12)

[m]

0.203)

Amaprop

6 Commissioning/Start-up/Shutdown

6.2.2.2 Fluid temperature

DANGER

Fluid temperature

Explosion hazard!

▷ Never operate the submersible mixer at fluid temperatures exceeding those

specified in the data sheet or on the name plate.

DANGER

Fluid temperature

Danger of freezing!

▷ The submersible mixer is designed for operation in liquids. The submersible

mixer is not operational, and therefore must not be operated, under freezing

conditions.

6.2.2.3 Density of fluid handled

The power input of the submersible mixer will increase in proportion to the density

of the fluid handled.

CAUTION

Excessive density of the fluid handled

Motor overload!

▷ Observe the information on fluid density in the data sheet.

▷ Make sure the motor has sufficient power reserves.

6.2.2.4 Abrasive fluids

Do not exceed the maximum permissible solids content specified in the data sheet.

When the mixer is operated in fluids containing abrasive substances, increased wear

of the propeller and the shaft seal are to be expected. In this case, halve the intervals

commonly recommended for servicing and maintenance.

6.2.2.5 Flow behaviour of fluid handled

CAUTION

Deviations from permissible flow behaviour in biogas applications.

Overloading of the submersible mixer!

▷ Observe the information given in the data sheet.

6.2.3 Supply voltage

DANGER

Non-compliance with permissible supply voltage tolerances

Explosion hazard!

▷ Never operate an explosion-proof submersible mixer outside the specified

range.

The maximum permissible operating voltage deviation is ±10%, for explosion-proof

mixers ±5% of the rated voltage. The voltage difference between the individual

phases must not exceed 1%.

Amaprop

29 of 60

6 Commissioning/Start-up/Shutdown

6.2.4 Frequency inverter operation

DANGER

Operation outside the permitted frequency range

Explosion hazard!

▷ Never operate an explosion-proof submersible mixer outside the specified

range.

Frequency inverter operation of the submersible mixer is permitted in the frequency

range from 25 to 50 Hz. In biogas applications, frequency inverter operation is

permitted in the frequency range from 30 to 50 Hz.

6.3 Shutdown/storage/preservation

6.3.1 Measures to be taken for shutdown

WARNING

Fluids posing a health hzard

Hazard to persons and the environment!

▷ Submersible mixers used in fluids posing a health hazard must be

decontaminated.

▷ Wear safety clothing and a protective mask, if required.

▷ Observe all legal regulations on the disposal of harmful substances.

WARNING

Submersible mixer started up inadvertently

Risk of injury by moving parts!

▷ Always make sure the electrical connections are disconnected before carrying

out work on the submersible mixer.

▷ Make sure that the submersible mixer cannot be started up unintentionally.

Submersible mixer remains installed

DANGER

Persons entering the tank

Electric shock!

▷ Never start up the submersible mixer when there are persons inside the tank.

▷ Disconnect or electrically disable the submersible mixer before entering the

tank.

WARNING

Hands, other body parts, or foreign objects in the propeller or propeller intake area

Risk of personal injury! Damage to the submersible mixer!

▷ Never place your hands, other body parts or foreign objects into the propeller

or propeller intake area.

▪ For longer standstill times, switch on the submersible mixer regularly once a

month to quarterly and allow to run for approx. one minute.

This will avoid the formation of deposits on the surface of the submersible mixer.

Submersible mixer is removed and stored

✓ Safety regulations are observed.

1. Clean submersible mixer.

30 of 60

Amaprop

6 Commissioning/Start-up/Shutdown

2. Perform maintenance. (⇨ Section 7.2.1 Page 33)

Follow instructions for maintenance. (⇨ Section 7.1 Page 32)

6.4 Returning to service

For returning the submersible mixer to service observe the sections on

commissioning/start-up and the operating limits (⇨ Section 6.2 Page 26).

For returning the mixer to service after storage also follow the instructions for

maintenance/inspection. (⇨ Section 7.2 Page 33)

NOTE

On submersible mixers older than 5 years we recommend replacing all elastomer seals.

Amaprop

31 of 60

7 Servicing/Maintenance

7 Servicing/Maintenance

7.1 Safety regulations

The operator ensures that all maintenance, inspection and installation work is

performed by authorised, qualified specialist personnel who are thoroughly familiar

with the manual.

DANGER

Sparks produced during maintenance work

Explosion hazard!

▷ Always perform maintenance work on explosion-proof submersible mixers

outside potentially explosive atmospheres only.

DANGER

Improper transport

Danger to life from falling parts!

Damage to the submersible mixer!

▷ Use the attachment point provided (lifting lug or bail) for attaching lifting

accessories.

▷ Never suspend the submersible mixer by its power cable.

▷ Never use the lifting ropes included in KSB's scope of supply for lifting loads

other than the KSB product supplied.

▷ Safely attach lifting ropes to the submersible mixer and crane.

▷ Protect the power cable against damage.

▷ Maintain adequate safety distance during lifting operations.

WARNING

Submersible mixer started up inadvertently

Risk of injury by moving parts!

▷ Always make sure the electrical connections are disconnected before carrying

out work on the submersible mixer.

▷ Make sure that the submersible mixer cannot be started up unintentionally.

WARNING

Fluids posing a health hazard or hot fluids

Risk of personal injury!

▷ Observe all relevant laws.

▷ Take appropriate measures to protect persons and the environment.

▷ Decontaminate submersible mixers used in fluids posing a health hazard.

NOTE

Special regulations apply to repair work on explosion-proof submersible mixers.

Modification or alteration of the submersible mixers may affect explosion protection and

is only permitted after consulting the manufacturer.

NOTE

A regular maintenance schedule will help avoid expensive repairs and contribute to

trouble-free, reliable operation with a minimum of maintenance expenditure and work.

32 of 60

Amaprop

7 Servicing/Maintenance

NOTE

All maintenance, service and installation work can be carried out by KSB Service or

authorised workshops. Find your contact in the attached "Addresses" booklet or on the

Internet at "www.ksb.com/contact".

Never use force when dismantling and reassembling the submersible mixer.

7.2 Servicing/inspection

KSB recommends regular maintenance in accordance with the following plan:

Table 7: Maintenance measures overview

Maintenance interval

After 8000 operating hours4)

After 16,000 operating hours5)

Every five years

Maintenance measures

Insulation resistance measurement (⇨ Section 7.2.1.1 Page 33)

Check the electrical connection lines (⇨ Section 7.2.1.2 Page 33)

Visual inspection of shackle/lifting rope (wastewater treatment plant

application) (⇨ Section 7.2.1.3 Page 34)

Visual inspection of shackle/lifting rope (biogas system application) (⇨ Section

7.2.1.3 Page 34)

Check sensors (⇨ Section 7.2.1.4 Page 34)

Lubricant change (⇨ Section 7.2.1.5 Page 34)

General overhaul

7.2.1 Inspection work

7.2.1.1 Measuring the insulation resistance

✓ The submersible mixer has been disconnected in the control cabinet.

✓ Use an insulation resistance measuring device.

✓ The max. measuring voltage is 1000 V.

1. Measure winding against earth.

To do so, connect all winding ends together.

2. Measure winding temperature sensor against earth.

To do so, connect all core ends of the winding temperature sensors together and

connect all winding ends to earth.

⇨ The insulation resistance of the core ends against earth must not be lower than

1 MΩ.

If the resistance measured is lower, cable and motor resistance must be measured

separately. Disconnect the power cable from the motor for this purpose.

NOTE

If the insulation resistance for the power cable is lower than 1 MΩ, the power cable is

defective and must be replaced.

NOTE

If the insulation resistance values measured on the motor are too low, the winding

insulation is defective. The submersible mixer must not be returned to service in this

case.

7.2.1.2 Checking the power cables

Visual inspection

1. Inspect the power cable for visual damage.

2. Replace any damaged components by original spare parts.

4)

5)

At least once per year

At least every three years

Amaprop

33 of 60

7 Servicing/Maintenance

Checking the earth

conductor

1. Measure the resistance between earth conductor and earth.

The resistance must be lower than 1 Ω.

2. Replace any damaged components by original spare parts.

DANGER

Defective earth conductor

Electric shock!

▷ Never switch on a submersible mixer with a defective earth conductor.

7.2.1.3 Checking the shackle/lifting rope

Visual inspection

✓ The submersible mixer has been lifted out of the fluid handled and cleaned.

1. Inspect the shackle/lifting rope and all fixing elements for visual damage.

2. Replace damaged components by original spare parts.

7.2.1.4 Checking the sensors

CAUTION

Excessive test voltage

Damage to the sensors!

▷ Never test the sensors with voltages exceeding 30 V.

The tests described below measure the resistance at the core ends of the power

cable. The actual function of the sensors is not tested.

Temperature sensors in

the motor winding

Table 8: Resistance of temperature sensors in motor winding

Measurement between terminals ...

10 and 11

Resistance

100 Ω - 1000 Ω

If the tolerances indicated are exceeded, disconnect the power cable at the

submersible mixer and repeat the check inside the motor.

If tolerances are exceeded here, too, the winding will have to be replaced.

Leckage sensor in the

motor

Table 9: Resistance of leakage sensor in the motor

Measurement between terminals ...

9 and earth conductor (PE)

Resistance

> 60 kΩ

Lower resistance values suggest water ingress into the motor. In this case the motor

must be opened and overhauled.

Leakage sensor at

mechanical seal (optional)

Table 10: Resistance of leakage sensor at mechanical seal

Measurement between terminals ...

6 and 7

Resistance

> 60 kΩ

Lower resistance values suggest liquid ingress into the leakage chamber. In this case

the leakage chamber must be checked. (⇨ Section 7.2.1.5.3 Page 36)

7.2.1.5 Lubrication and lubricant change

7.2.1.5.1 Lubricant quality

Recommended quality of

mechanical seal lubricant

The lubricant reservoir is filled at the factory with an environmentally friendly, nontoxic lubricant of medical quality (unless otherwise required by the customer).

The following lubricants can be used for lubricating the mechanical seals:

▪ Thin-bodied paraffin oil; producer: Merck, No.: 7174

▪ Merkur white oil Pharma 40; producer: DEA

34 of 60

Amaprop

7 Servicing/Maintenance

Alternative

▪ Equivalent brand of medical quality, non-toxic

▪ Water-glycol mixture

▪ All non-doped and doped motor oils of classes SAE 10W to SAE 20W

Recommended quality of

gear unit lubricant

▪ Lubricant to ISO VG 320 (viscosity 320) for fluid temperatures ≤ 45 °C

▪ Fully synthetic gear oil CLP 320 PAO (based on polyalphaolefines) for fluid

temperatures between 45 °C and 60 °C

WARNING

Contamination of fluid handled by lubricant

Hazardous to persons and the environment!

▷ Using machine oil is only permitted if the oil can be disposed of properly.

7.2.1.5.2 Lubricant quantity

Mechanical seal

Table 11: Quantity of mechanical seal lubricant

Size

Lubricant quantity

[l]

1.9

All

Gear unit

Table 12: Shaft centreline heights (gear unit)

Gear unit

Shaft centreline height

[mm]

158

192

SP 189

SP 190

Lubricant quantity

[l]

1.9

2.6 6)

Table 13: Quantity of gear unit lubricant

Size

Motor

Gear unit

1000

1200, 1400, 1600, 1800, 1801

1200, 1400, 1600, 1800, 1801

V 28-2000, V 31-2000

V 35-2000 bis V 53-2000

V 24-2200, V 28-2200

V 32-2200 bis V 50-2200

V 24-2500, V 28-2500

V 30-2500 bis V 46-2500

K 38-2500, K 42-2500

All

14, 24, 34

44, 54

14, 24,

24, 34, 44, 54

14, 24,

24, 34, 44, 54

14, 24,

24, 34, 44, 54

64

SP 190

SP 189

SP 190

SP 189

SP 190

SP 189

SP 190

SP 189

SP 190

SP 190

6)

Lubricant quantity

[l]

2.6 6)

2.0

2.6

2.0

2.6

2.0

2.6

2.0

2.6

2.6

For Amaprop 1000 with pitch adapter (15° or 30° upward pitch) = 4.3 Liter

Amaprop

35 of 60

A

7 Servicing/Maintenance

Fig. 12: Shaft centreline height - Gear unit

A

Centreline height

7.2.1.5.3 Checking the leakage chamber

WARNING

Fluids posing a health hazard

Hazard to persons and the environment!

▷ Collect and properly dispose of flushing liquid and any residues of the fluid

handled.

▷ Wear safety clothing and a protective mask, if required.

▷ Observe all legal regulations on the disposal of substances posing a health

hazard.

Checking the leakage chamber serves to assess the function of the drive-end

mechanical seal.

903.03

411.03

903.04

411.04

Fig. 13: Checking the leakage chamber

✓ A suitable container for the leakage is on hand.

✓ The submersible mixer is placed horizontally on a level surface.

1. Place the container underneath screw plug 903.04.

2. Remove screw plugs 903.03/04 with joint rings 411.03/04.

36 of 60

Amaprop

7 Servicing/Maintenance

⇨ If there is no leakage or, after several years of operation, only a small

amount (less than 0.2 litre), the mechanical seals are working properly. If the

leakage exceeds 0.2 litres, the mechanical seals are defective and must be

replaced.

3. Fit screw plugs 903.03/04 with joint rings 411.03/04 again.

7.2.1.5.4 Draining the lubricant

WARNING

Lubricants posing a health hazard and/or hot lubricants

Hazard to persons and the environment!

▷ When draining the lubricant take appropriate measures to protect persons and

the environment.

▷ Wear safety clothing and a protective mask, if required.

▷ Collect and dispose of any lubricants.

▷ Observe all legal regulations on the disposal of fluids posing a health hazard.

WARNING

Excess pressure in the lubricant reservoir

Liquid spurting out when the lubricant reservoir is opened at operating temperature!

▷ Open the screw plug of the lubricant reservoir very carefully.

Amaprop

37 of 60

7 Servicing/Maintenance

A

903.02

411.02

Fig. 14: Draining the lubricant (propeller not shown)

A Lubricant drain plug

1. Position the submersible mixer as shown.

2. Place a suitable container under the screw plugs.

3. Unscrew the lubricant drain plug on the gear unit and drain off the lubricant.

4. Screw the lubricant drain plug of the gear unit back in.

5. Undo screw plug 903.02 with joint ring 411.02 and drain off the lubricant.

6. Close screw plug 903.02 again, fitting a new joint ring 411.02.

38 of 60

Amaprop

7 Servicing/Maintenance

7.2.1.5.5 Filling in the lubricant

WARNING

Lubricants posing a health hazard

Hazard to persons and the environment!

▷ When filling in the lubricant take appropriate measures to protect persons and

the environment.

CAUTION

Lubricant level too high

Mechanical seal operation is impaired!

▷ Always place the submersible mixer in horizontal position (as shown) for filling

in the lubricant.

A

B

903.01

411.01

Fig. 15: Filling in lubricant (propeller not shown)

A Lubricant check plug (gear unit)

B Lubricant filler plug (gear unit)

✓ The submersible mixer has been positioned as shown.

Amaprop

39 of 60

7 Servicing/Maintenance

1. Unscrew screw plug 903.01 with joint ring 411.01.

2. Fill the lubricant through the lubricant filler opening until the lubricant reservoir

overflows.

3. Close screw plug 903.01 again, fitting a new joint ring 411.01.

4. Unscrew the lubricant check plug on the gear unit.

5. Unscrew the lubricant filler plug on the gear unit.

6. Fill the lubricant through the lubricant filler opening into the lubricant reservoir

until the lubricant flows out of the lubricant check opening.

7. Screw the lubricant filler plug of the gear unit back in.

8. Screw the lubricant check plug of the gear unit back in.

7.3 Drainage/disposal

WARNING

Fluids posing a health hazard

Hazard to persons and the environment!

▷ Submersible mixers used in fluids posing a health hazard must be

decontaminated.

▷ Collect and properly dispose of flushing liquid and any liquid residues.

▷ Wear safety clothing and a protective mask, if required.

▷ Observe all legal regulations on the disposal of harmful substances.

1. Always flush the submersible mixer if it has been used for handling noxious,

explosive, hot or other hazardous fluids.

2. Always flush and clean the submersible mixer before sending it to the workshop.

Make sure to add a certificate of decontamination. (⇨ Section 11 Page 57)

7.4 Dismantling the submersible mixer

7.4.1 General information/Safety regulations

WARNING

Work on the submersible mixer by unqualified personnel

Risk of personal injury!

▷ Always have repair and maintenance work performed by specially trained,

qualified personnel.

WARNING

Submersible mixer started up inadvertently

Risk of injury by moving parts!

▷ Always make sure the electrical connections are disconnected before carrying

out work on the submersible mixer.

▷ Make sure that the submersible mixer cannot be started up unintentionally.

WARNING

Hot surface

Risk of personal injury!

▷ Allow the submersible mixer to cool down to ambient temperature.

40 of 60

Amaprop

7 Servicing/Maintenance

WARNING

Improper lifting/moving of heavy assemblies or components

Personal injury and damage to property!

▷ Use suitable transport devices, hoisting equipment and lifting tackle to move

heavy assemblies or components.

WARNING

Fluids posing a health hzard

Hazard to persons and the environment!

▷ Submersible mixers used in fluids posing a health hazard must be

decontaminated.

▷ Wear safety clothing and a protective mask, if required.

▷ Observe all legal regulations on the disposal of harmful substances.

WARNING

Components with sharp edges

Risk of cutting or shearing injuries!

▷ Always use appropriate caution for installation and dismantling work.

▷ Wear work gloves.

For dismantling and reassembly observe the general assembly drawing. (⇨ Section 9.1

Page 49)

NOTE

All maintenance, service and installation work can be carried out by KSB Service or

authorised workshops. Find your contact in the attached "Addresses" booklet or on the

Internet at "www.ksb.com/contact".

7.4.2 Removing the propeller

23-9

550.01

914.06

Fig. 16: Removing the propeller

✓ The submersible mixer has been lifted out of the tank, cleaned and placed

outside the tank as per operating instructions.

1. Unscrew propeller screw 914.06 and disc 550.01.

2. Screw a forcing screw into propeller 23-9 and pull off the propeller. (⇨ Section

9.4 Page 55)

Amaprop

41 of 60

7 Servicing/Maintenance

7.4.3 Removing the mechanical seals

CAUTION

Improper removal of mechanical seal

Damage to the shaft!

▷ Care must be taken when loosening and removing the mechanical seal.

932.03

471

932.04

932.05

433.01

433.02

Fig. 17: Removing the mechanical seal

✓ The propeller has been removed.

1. Undo circlip 932.05.

2. Take out mechanical seal 433.02.

3. Undo circlip 932.03.

4. Take out seal cover 471.

5. Undo circlip 932.04.

6. Take out mechanical seal 433.01.

7.4.4 Dismantling the motor section

NOTE

Special regulations apply to repair work on explosion-proof submersible mixers.

Modification or alteration of the submersible mixers may affect explosion protection and

is only permitted after consulting the manufacturer.

NOTE

The motors of explosion-proof submersible mixers are supplied in "flameproof enclosure"

type of protection. Any work on the motor section which may affect explosion protection,

such as re-winding and repair work involving machining, must be inspected and

approved by an approved expert or performed by the motor manufacturers. No

modifications may be made to the internal configuration of the motor space. Repair work

at the flameproof joints must only be performed in accordance with the manufacturer's

instructions. Repair to the values in tables 1 and 2 of EN 60079-1 is not permitted.

When dismantling the motor section and the power cables make sure that the cores/

terminals are clearly marked for future reassembly.

42 of 60

Amaprop

7 Servicing/Maintenance

7.5 Reassembling the submersible mixer

7.5.1 General information/Safety regulations

WARNING

Improper lifting/moving of heavy assemblies or components

Personal injury and damage to property!

▷ Use suitable transport devices, hoisting equipment and lifting tackle to move

heavy assemblies or components.

CAUTION

Improper reassembly

Damage to the submersible mixer!

▷ Reassemble the submersible mixer in accordance with the general rules of

sound engineering practice.

▷ Use original spare parts only.

NOTE

Before reassembling the motor section, check that all joints relevant to explosion

protection (flamepaths) are undamaged. Any components with damaged flamepaths

must be replaced. Refer to the "Flamepaths" annex for the position of the flamepaths.

Sequence

Sealing elements

Always reassemble the submersible mixer in accordance with the corresponding

general assembly drawing.

▪ O-rings

– Check O-rings for any damage and replace by new O-rings, if required.

– Never use O-rings that have been glued together from material sold by the

metre.

▪ Assembly adhesives

– Avoid the use of assembly adhesives, if possible.

Tightening torques

For reassembly, tighten all screws and bolts as specified in this manual. (⇨ Section 7.6

Page 46)