PETE403

advertisement

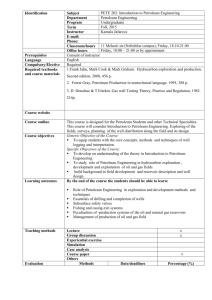

Department of Petroleum Engineering PETE 403: Petroleum Production Engineering 3 credits: 3 50-minute lectures per week Required Catalog Description: The course introduces the student to topics of inflow and outflow performance, multi-phase flow in pipes, nodal analysis and production optimization and artificial lift with stress on electric submersible pumps and gas lift systems. Oil and water treatment and separation processes are introduced. Theoretical background calculations as well as design and economic applications are covered in sufficient details. Prerequisite: CHE 204: Transport Phenomena I PETE 302: Well Completion Textbook: B. Guo, W.C. Lyons and A. Ghalambor. (2007). Petroleum Production Engineering: A Computer-Assisted Approach, Elsevier Course Objectives: 1. Enable the student to gain experience in methods of enhancing well productivity within optimum technical and economic conditions. 2. Provide an integrated design experience and practice team-spirit through project work. 3. Develop proficiency in the application of computer software for performing design calculations. Topics and Hours: Topic 1. Introduction to production engineering; development and operations 2. Multi-phase flow in vertical and horizontal wells 3. Inflow and outflow performance in vertical and horizontal wells 4. Nodal analysis and production optimization 5. Exam 1 6. Artificial lift methods and applications 7. Electric submersible pump 8. Gas lift 9. Exam 2 10. Surface production facilities over view 11. Multistage separation 12. Produced oil and water treatment Total Hours Hours 1 7 5 5 1 2 7 7 1 1 3 4 ----45 Method of Evaluation: Homework & Quizzes First exam Second exam Attendance Term project Final exam 15% 20% 20% 5% 10% 30% Contributions to Professional Component: Engineering Science and Design: The course with its design orientation enables the student to understand the principles of modern production engineering. The use of computer software helps the student develop skill to perform computer-aided solutions. The term project trains the student further in communication and interpersonal skills. Relationship of Course Learning Outcomes to Program Educational Outcomes: Course Learning Outcome Program Educational Outcome 1. Ability to apply reservoir and Ability to design a system, component, mechanical data to diagnose well or process to meet the desired needs conditions and calculate pressure within realistic constraints such as losses in the production system. economic, environmental and safety. 2. Ability to perform design calculations for the production system components to specify their dimensions and mechanical strength and hence choose them from industry available products. 3. Ability to implement technical and economic constraints to optimize the performance of a producing well. 4. Execution of a team project to perform in-depth study of one of the course topics including preparing a technical report and making an oral presentation. Prepared by: Dr. Mahmoud E. Doklah, April, 2010. Instructor: Dr. Mahmoud E. Doklah, Ph.D., Associate Professor, Department of Petroleum Engineering, Room 3-213, 860-4235, mdoklah@kfupm.edu.sa