Sports Car Club of America: Main

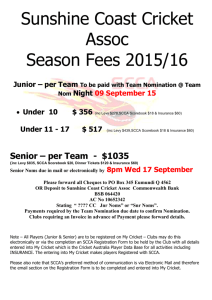

advertisement