Development of new technology for the

advertisement

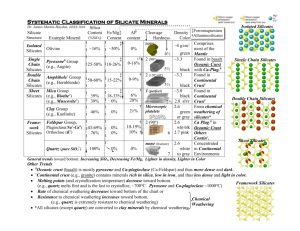

Development of new technology for the manufacturing of nanocrystalline silicate scintillation materials Nikoloz Jalabadze*, Roin Chedia, Tengiz Kukava and Lili Nadaraia Georgian Technical University, 77, Kostava St., Tbilisi 0175, Georgia Quality and reliability of the provided scientific researches were greatly enhanced by using Ce-doped lutetium silicates. Lutetium silicates LSO and LPS are usually applied in scintillators in the form of single crystals. Despite of the fact that using of these materials counts rather a long period, the works on advancing the manufacturing technologies with the goal to improve performance of these materials are still in progress. A new technology for manufacturing of lutetium silicates has been developed offering nanocrystalline scintillators instead of single crystalline ones. The offered technology is based on sol-gel method (Fig.1a) which makes it possible to fabricate mono-phase scintillation materials in the form of nanocrystals (Fig.1b,c). The developed technology provides preparation of scintillation materials not only from the widely spread tetraethoxycilan but also from various other silicon-contained compounds. The technology ensures phase purity that being very important for the manufacturing of Fig. 1. Scheme of the technology for manufacturing of lutetium silicate scintillation materials (a); diffraction patterns of the nanocrystalline LSO (b) and LPS (c) samples. materials with high performance. The obtained lutetium oxyortho- and pyrosilicate are characterized with high stability and there have not been detected any events of their inter-transferring phenomenon even at high temperatures. Compaction of scintillation powders in massive samples are realized with the help of an original device the principle of which is based on the method of Spark Plasma Synthesis (SPS). Using of optimal modes makes possible to retain nanostructural condition in the obtained massive samples. * corresponding author e-mail: Jalabadze@gtu.ge