Are you meeting your Customer`s Needs

advertisement

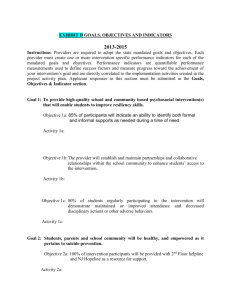

Are you meeting your Customer's Needs? How do you know if your customer's requirements are being met? Indicators, with facts help us determine whether or not our processes are capable of meeting our customer's needs. An indicator is defined as a measure of meeting valid requirements. Indicators are used to monitor both the quality of the service or outcome of the process (quality indicators) and the effectiveness or condition of a part of the work process (process indicators). Whichever type of indicator you use, all indicators should be: Measurable Verifiable (able to observe and audit) Cost Effective They can be expressed quantitatively (in time, dollars, customer specifications, etc.) Multiple, independent observers of the process must be able to agree on the results obtained from measuring the process. Accurate records to be kept so that the measurements can be tracked over time. Indicators must be chosen with economy of time and cost in mind. Ideally, dates for indicators will be available from existing sources and/or management information systems. The benefits gained from using an indicator should exceed the costs associated with tracking it. Quality Indicators: Measures used to determine the quality of the product or service provided to the customers. By linking them closely to customer's negotiated requirements and reasonable expectations (valid requirements) we are able to accurately assess our performance. In most instances, customers have multiple valid requirements involving the accuracy, timeliness, dependability or cost of the product/service provided. Before developing quality indicators, be sure all of the valid requirements are understood. While quality indicators assess the degree of conformance to valid requirements, they are usually after the fact and are not useful in identifying the cause of nonconformance. A different type of indicator, upstream in the process is needed for this purpose. Process Indicators: Upstream measures taken at critical points in a process for assessing the performance of a process before it's too late to do anything about it. Long before the service or outcome of the process occurs, these indicators serve as early warning signs that something is wrong. By monitoring and evaluating process indicators, corrective action can be taken on a process before there is a significant adverse impact on the outcome of a process, hence, to our customers.