p-Bromoaniline Synthesis: A Lab Protocol

Page 1

EXP-10

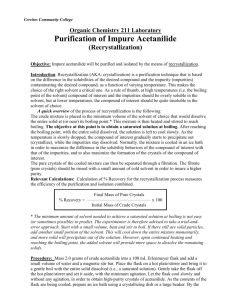

SYNTHESIS OF p-BROMOANILINE

CHEM 233L

Introduction:

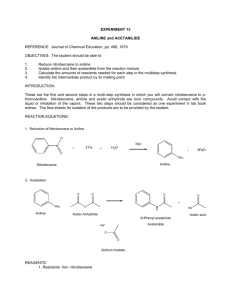

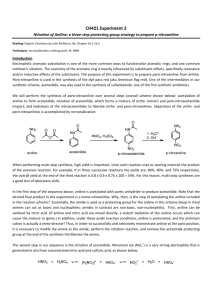

In this experiment, p-bromoaniline was synthesized in three steps starting from aniline. Since the amino group of aniline is a strong activator of aromatic ring, direct bromination is impractical (equation 1). In order to make a desired product, amino group needed to be protected as the acetamide which also maintained ortho and para position but slowed down the rate of reaction (equation 2). Slow reaction rate would increase the possibility of obtaining the para-position product (equation 3). The acetamide can be hydrolyzed back to the amine (equation 4). This strategy of protection and deprotection is a very important tool in organic chemistry, especially in multi-step synthesis.

Equation 1:

NH

2

NH

2

Br Br

Br

2

Equation 2:

Aniline

NH

2

O O

O

Acetic anhydride

Br plus mono-and-di-derivative

O

HN

Acetanilide

Equation 3:

Aniline

O

HN

Br

2

HN

O

Equation 4:

Acetanilide

O

HN

Br

Bromoacetanilide

NH

2

Acid hydrolysis

Br

Bromoacetanilide

Br

4-bromoaniline

Table of Physical data:

Compound Molecular

Weigh (g)

NH

2

93.128

Amount Density

(g/ml)

Moles Melting point m.p. o C

2.0 ml 1.021 0.0219 -6.2

Boiling point b.p o C

184

Page 2

Aniline

HCl concentration

Water

Cl -

NH

3

+

36.460

18.015

129.588

Anilinium chloride

O O 102.089

O

Acetic anhydride

O

Na +

O -

Sodium acetate

O

82.034

135.165

HN

2.0 ml

2.56 ml

0.909

1.221

1.08

3.3147 g 1.45

0.6718 g 1.219

0.0498

50 ml 0.909 ---

0.0270

0.0404

-114.24

0

198

-73.1

58

0.00197 114.3

-85.06

100

245

139

304

Acetanilide

Acetanilide

Safety notes :

Bromine is very corrosive. Wear gloves when using it.

p-Bromoaniline is harmful if inhaled or absorbed through the skin

Aniline is highly toxic. It is possible mutagen, sensitizer, and readily absorbed through the skin.

Page 3

Procedure:

EXP-10A:

1.

Dilute 2.0 ml of concentration HCl in 50 ml of water in a 125 ml flask, then add

2.05g (2.0 ml) of aniline.

2.

Stir the mixture until the aniline completely dissolves. HCl and aniline reacts forming anilinum chloride. (A reaction for this step was included in your report).

3.

Add 2.77g (2.56 ml) of acetic anhydride, stir until it is dissolves and immediately pour a solution of 3.3g of sodium acetate in 10 ml of water into the flask.

4.

After complete addition, stir vigorously for 5 minutes, then cool in ice.

Crystallization should occur. When no more crystals seem to form (5—10 minutes), vacuum filter the acetanilide, wash the crystals with small volumes of cold water and air dry for 5 minutes.

5.

Pure acetanilide is usually obtained as white flakes. Recrystallize the obtained acetanilide from a minimum of hot water. Use 10 ml of water to start and increase the amount of water depending on the amount of acetanilide.

6.

If the initial crystals were not white, add 0.5g of decolorizing charcoal to the product in water and then heat to gently boiling.

7.

Remove the charcoal by hot gravity filtration ,using two pieces of fluted filter paper. To avoid contaminating the filtrate with charcoal, do not overflow the filter funnel.

8.

After recrystallization, wash the crystals again with small volumes of cold water.

9.

Dry the product, obtain an IR and melting point.

10.

The typical yield is 2.0 g. Submit 100mg of your product and the rest for the next experiment.

Table of physical data EXP-10B:

Compound Molecular

Weigh (g)

Amount Density

(g/ml)

O 135.165 ---- 1.219

Moles

----

Melting point m.p.

o C

114.3

Boiling point b.p.

o C

304

HN

Acetanilide

Bromine

Acetic acid

Solvent

O

HN

159.808

60.052

214.061

1.5 ml

2.0 ml

3.119

1.049

0.0293 -7.2

0.0349 16.6

165-166

58.7

117.9

Br p-Bracetanilide

Page 4

HN

O 214.061

Br m-Bracetanilide

O 214.061

HN

Br o-Bracetanilide

NaHSO

3

Reducing agent

Ethanol

Recystallized solvent

104.055 Reduced

46.068 bromine

1.48

2.0 ml 0.789

---

0.0342 -114.1 78.3

Procedure:

EXP-10B:

1.

Place 1.0 g of acetanilide in a 50 ml Erlenmeyer flask.

2.

Add 4.0 ml of acetic acid and swirl until the solid dissolves.

3.

Place a magnetic stirring bar in the flask and place the flask on a hot plate and clamp.

4.

In the hood, obtain 2.5 ml of 1:4 of 4.1 M bromine/ acetic acid.

5.

In the hood, add the bromine drop-wise using a disposable Pasteur pipet over a period of 5 minutes. The flask was covered with a small beaker and stir the reaction mixture for another 15 minutes to complete the reaction.

6.

In the mean time, clean the used pipet and graduated cylinder with 2 ml of aqueous

NaHSO

3

. Bromine will be destroyed or its color will change from red to clear by sodium bisulfide.

7.

In the hood, pour the reaction mixture into a 150 ml beaker containing 30 ml of water. Rinse the reaction flask with additional 10 ml of water. A precipitate should form.

8.

Stir the precipitate with a glass rod to break up any chunks. If the solution still has an orange color from excess bromine, add aq. NaHSO

3

(sodium bisulfite) drop wise until the color is discharged.

9.

Collect the crude product by vacuum filtration and wash the solid 4 times with 10 ml of cold water (mix equal parts of ice and water).

10.

Transfer the crude solid into a 125 ml Erlenmeyer flask.

11.

Recrystallize the major product from a minimum amount of hot ethanol. It is recommended to try to dissolve the solid in approximately 5 ml of boiling ethanol.

Page 5

Additional ethanol was added if necessary. Keep track of the amount of solvent used.

12.

While heating, add 1ml of water for every 2ml of ethanol used (or half the volume).

13.

Allow the solution to cool down at room temperature. Crystals should appear. Chill the crystallized material for 5 minutes and then isolate by vacuum filtration. Rinse your product with cold water.

14.

Dry the crystals overnight.

15.

Calculate the % yield. Obtain an IR and a melting point. Save 100 mg and submit with other product. The rest is used for the next step.

Table of physical data:

EXP-10C:

Compound MW (g) Amount Density

(g/ml)

O 214.061 0.6525 ---

Moles

0.00305 m.p. o C b.p.

165-166 o C

HN

Br p-Br-acetanilide

O

HO

S

OH

O

Conc H

2

SO

4

6 M NaOH

NH

2

98.073 5ml 1.84

39.997 25 ml 2.13

172.024 0.3782 g 1.5

0.0938 3

1.33

0.00220

318

66.4

280

1390

---

Br p-bromoaniline

H 84.932 30 ml 2.165 -96.7 39.8

H

Cl

CH

2

Cl

2

NaCl

Ethanol

58.443 20 ml

46.068 ---

0.789

0.789

---

---

801

-114.1

1413

78.3

Procedure:

EXP-10C:

1.

Transfer 1.0g of p-bromo-acetanilide into a 100 ml round-bottomed flask. Add 10 ml of water into the flask.

2.

Chill the mixture and add 10 ml of concentrated sulfuric acid carefully and slowly.

Page 6

3.

Heat the mixture to reflux for 1 hour.

4.

Initially the p-bromoacetanilide will be insoluble but as the reaction progresses it will completely dissolve.

5.

Stop the reaction and wait 5-10 minutes for the mixture to cool off.

6.

Analyze the crude reaction mixture by TLC by using 10 ml of Hex/EtAc 8:2 as solvent.

7.

Dissolve the samples in EtOAc (ethyl acetate)

8.

Spot the p-bromoactanilide, the crude mixture and a co-spot and visualize by

U.V. Estimate the extent of the reaction. The product should stay at the origin.

9.

Is there any starting material left? Is the reaction complete? If the reaction is not complete, continue the refux for another 30 minutes to an hour.

10.

Upon completion, cool the reaction flask and pour the contents into 20 mL of iced-cold water.

11.

Neutralize the acidic solution with 10 M NaOH. Theoretically, it should require

18 ml of 10 M NaOH to neutralize the sulfuric acid present.

12.

Add the aq NaOH solution portion-wise with the help of a Pasteur pipette.

13.

When half of the theoretical volume has been added to check the pH. Add enough

NaOH to bring the pH to 8. If a different concentration of NaOH is used, the required theoretical volume is calculated.

14.

Transfer the neutralized solution to a separatory funnel and extract the free amine with 3 X 10 ml of CH

2

Cl

2.

15.

Back extract the combined organic layer with 20 ml of water and 20 ml of saturated sodium chloride (NaCl).

16.

Dry the CH

2

Cl

2

over anhydride Na

2

SO

4

. Remove the drying agent by gravity filtration and evaporate the CH

2

Cl

2

in the hood over low heat.

17.

Remove the solvent, as the oily residue begins to crystallize.

18.

Allow the crystals to dry overnight. Check the purity of the product by IR.

19.

Check the melting point of final product and calculate the % yield.

Reference: