Epoxy Solvent-Free Coating System

advertisement

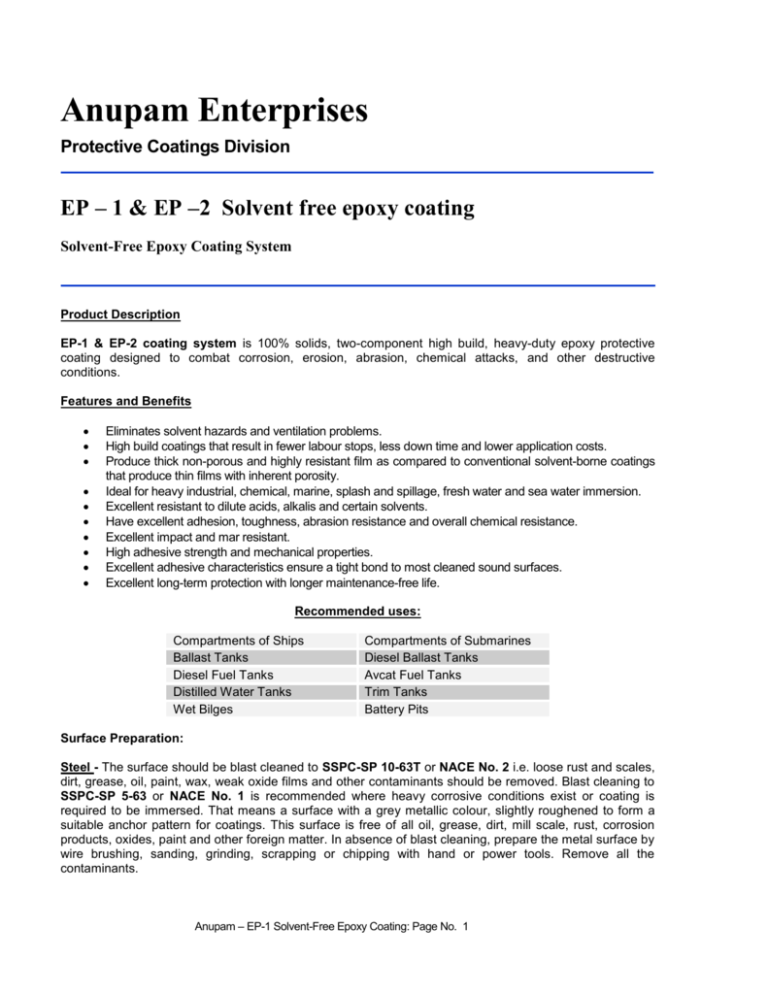

Anupam Enterprises Protective Coatings Division EP – 1 & EP –2 Solvent free epoxy coating Solvent-Free Epoxy Coating System Product Description EP-1 & EP-2 coating system is 100% solids, two-component high build, heavy-duty epoxy protective coating designed to combat corrosion, erosion, abrasion, chemical attacks, and other destructive conditions. Features and Benefits Eliminates solvent hazards and ventilation problems. High build coatings that result in fewer labour stops, less down time and lower application costs. Produce thick non-porous and highly resistant film as compared to conventional solvent-borne coatings that produce thin films with inherent porosity. Ideal for heavy industrial, chemical, marine, splash and spillage, fresh water and sea water immersion. Excellent resistant to dilute acids, alkalis and certain solvents. Have excellent adhesion, toughness, abrasion resistance and overall chemical resistance. Excellent impact and mar resistant. High adhesive strength and mechanical properties. Excellent adhesive characteristics ensure a tight bond to most cleaned sound surfaces. Excellent long-term protection with longer maintenance-free life. Recommended uses: Compartments of Ships Ballast Tanks Diesel Fuel Tanks Distilled Water Tanks Wet Bilges Compartments of Submarines Diesel Ballast Tanks Avcat Fuel Tanks Trim Tanks Battery Pits Surface Preparation: Steel - The surface should be blast cleaned to SSPC-SP 10-63T or NACE No. 2 i.e. loose rust and scales, dirt, grease, oil, paint, wax, weak oxide films and other contaminants should be removed. Blast cleaning to SSPC-SP 5-63 or NACE No. 1 is recommended where heavy corrosive conditions exist or coating is required to be immersed. That means a surface with a grey metallic colour, slightly roughened to form a suitable anchor pattern for coatings. This surface is free of all oil, grease, dirt, mill scale, rust, corrosion products, oxides, paint and other foreign matter. In absence of blast cleaning, prepare the metal surface by wire brushing, sanding, grinding, scrapping or chipping with hand or power tools. Remove all the contaminants. Anupam – EP-1 Solvent-Free Epoxy Coating: Page No. 1 Anupam – EP-1- Solvent-Free Epoxy Coating: TECHNICAL DATA Name/Description Type Composition Colour Finish Solids by Volume & Weight (mixed) Mixing Ratio Pot Life @ 30° C Dry film thickness per coat Coverage-(theoretical-no loss) Serviceability @ 30° C - Surface Dry - Hard Dry - Full Cure Dry heat resistance Application Temperature -minimum -maximum Relative Humidity Flash Point Solvent/Thinner Resistance to boiling water @ 96° C for 6 hours Resistance to corrosion under conditions of condensation @ 38° C for 1000 hours Resistance to Salt Spray for 1000 hours Packing Shelf Life EP-1 Primer Two pack cold cured Epoxy Resin / Special Polyamide Curing Agent suitably pigmented. White & Pink Smooth and Glossy EP-2 Topcoat Two pack cold cured Epoxy Resin / Special Polyamide Curing Agent suitably pigmented. White & Pink Smooth and Glossy 100% 100% Base : Hardener 4.5 : 1 by weight 2 hours 250 ± 25 microns 4 m² /litre at 250 microns Base : Hardener 4 : 1 by weight 2 hours 250 ± 25 microns 4 m² /litre at 250 micron 5 hours 16 hours 7 days 120° C 5 hours 16 hours 7 days 120° C 10° C 35° C 90% Above 80° C Anusol - ETP Thinner 10° C 35° C 90% Above 80°C Anusol - ETP Thinner Unaffected Unaffected No Failure No Failure No Failure No Failure 3 & 30 litres 6 months 3 & 30 litres 6 months Clean - Up: Clean-up hands, tools, gloves etc. immediately with ANUSOL - ETP Epoxy Thinner. Caution: The job sites should be ventilated. The liquids may cause skin or eye irritation. Avoid direct contact with skin. Rub hands and face with a protective skin ointment. Before longer break periods and after completion of work, give the body careful washing. Rinse splashes from the eyes with plenty of water and borax solution. Wear protective clothing such as gloves, safety goggles and apron when mixing and applying Chemoguard. Keep away from reach of children and persons not trained in its use and not aware of the potential hazards involved. All components of this system are intended for use by professionals only. Anupam – EP-1 Solvent-Free Epoxy Coating: Page No. 2 Anupam – EP-1- Solvent-Free Epoxy Coating: Product Limitations: EP-1 & EP-2 coatings tend to change colour after few days if exposed to direct sunlight, certain gases and vapours and certain chemicals. It should be noted, however, chemical resistance and other properties of the coatings are not affected at all by discolouration. Notes Brushes and spray equipments should be cleaned with Anusol - ETP Epoxy Thinner. The contents should be stirred thoroughly prior to use. When overcoating the weathered or aged Chemoguard, ensure that the coating is fully free from all contamination such as oil, dust, grease, stains etc. The coating should be made dull with kitchen knife etc. Disclaimer: Information provided herein is based upon tests believed to be reliable. It does not guarantee the results to be obtained. Nor does it make any express and implied warranty or merchantability, or fitness for a particular purpose concerning the effects or results of such case. It does not release you from the obligation to test the products supplied by us as to their suitability for the intended uses. The application, surface preparation and use of the products are beyond our control and, therefore, entirely your own responsibility. Anupam Enterprises ‘Poddar Point’ 113 Park Street Block – B, 5th Floor Kolkata 700 016 West Bengal, India Phone: +91-33-22651204 & 22651205 Fax: +91-33-22651227 E-mail: info@anupampaints.com Web: http://www.anupampaints.com Anupam – EP-1 Solvent-Free Epoxy Coating: Page No. 3