Synthesis of an Aromatic Compound That Smells

advertisement

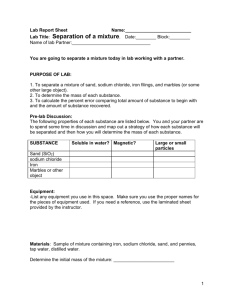

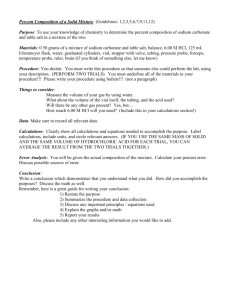

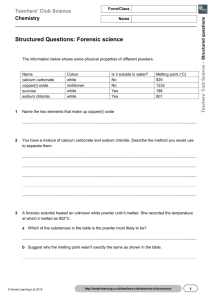

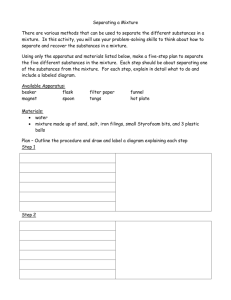

Synthesis of an Aromatic Compound That Smells like Gardenia From Styrene Heather Myers Math & Science Department, Cochise College, 901 N. Colombo Avenue, Sierra Vista, Arizona 85635-2317, United States of America April 22, 2004 This is a five-step synthesis going from styrene to styrene dibromide, then to phenylacetylene. Phenylacetylene is converted to acetophenone which in turn becomes alpha-methylbenzyl alcohol, which then is converted into alpha-methylbenzyl acetate, the final product. Through the course of these five reactions, the aromatic ring experiences the majority of the functional groups taught in the basic course of organic chemistry, making this a fairly good set of reactions for a lab in a class. They can be seen in the chemical structures of each molecule below. The low yield on the very first reaction – 12.17% which results in an overall yield of 3.73% alpha-methylbenyl acetate (1) would indicate that this series is probably not a good reaction for mass production of a perfume agent. Br A Br B C 2 1 styrene O C O CH3 CH3 CH3 E D 3 CH3 O OH 4 5 A. Tetrabutylammonium tribromide, dichloromethane, 12.17% yield B. Tetrabutylammonium hydrogen sulfate, 50% sodium hydroxide, hexane, 86.4% yield. C. 88% formic acid, reflux, 58.5% yield. D. Sodium borohydride, 95% ethanol. Step 2, 6M HCl (aq) 98% yield. E. Pyridine, dichloromethane, 61.87% yield. 1. Bauer, Kurt/Garbe, Dorothea; Common Fragrance and Flavor Materials. 1985 1 Conclusion This series of reactions was successfully carried out over the course of one semester in organic chemistry, after the first semester was spent honing the techniques necessary to complete them. For the first mentioned purpose of this series of reactions, mission accomplished. As for the gardenia fragrance, it actually caused dizziness and had a noxious odor, perhaps due to the high concentration in a small laboratory, but the conclusion must be negative at this time. Experimental Section 5 mL of dichloromethane and 500 microliters of styrene were placed in a 25mL Erlenmeyer flask equipped with a stirring bar. TBABr3 was then added (3.16g) over a period of 1 minute, resulting in a thick yellow gelatinous liquid. The reaction mixture was then washed with 3mL distilled water, then 3mL 5% sodium thiosulfate twice, then once more with 3mL distilled water. Solvent was dried with anhydrous sodium sulfate, then removed by rotary evaporator, 1.41g at an off-white color solid. It was then redissolved in ethanol and allowed to recrystalize. After recrystalizing, the solid weighed 0.14g, pure white in color, had a melting point of 64 degrees Celcius. 500 microliters of phenylacetylene, then 5mL of 88% formic acid were placed in a 10mL pear bottom flask equipped with a stirring bar. One hour was allowed for the reaction to elapse, and thin layer chromatography showed the reaction to be complete. The reaction mixture was dark brown. The mixture was transferred to centrifuge tube & washed twice with distilled water. 2mL of dichloromethane was added then allowed to separate then aqueous phase was removed, washed with dichloromethane, and all organic phase was combined. Organic phase was then washed twice with sodium carbonate solution, then twice with distilled water. Solvent was dried with anhydrous sodium sulfate, then removed by rotary evaporator, 0.32g, light yellow color liquid. 0.60g of styrene dibromine dibromide & 5mL of hexanes were placed in a 25 mL Erlenmeyer flask equipped with a stirring bar. 2.32g of tetrabutylammonium hydrogen sulfate (phase transfer catalyst) was then added. 1.45 mL of 12.5M NaOH was added dropwise and the flask was covered with a watch-glass. The reaction mixture became a thick yellow gel. Thin layer chromatography showed the reaction to be complete after 45 minutes. The mixture was transferred to centrifuge tube and washed with water, then all aqueous phase was removed, rinsed with hexane, and all organic material was combined. Solvent was dried with anhydrous sodium sulfate, then boiled off in a warm sand bath. Product was a transparent liquid, 0.2g. 500 microliters of acetophenone, then 5mL of 95% ethanol were placed in a 10mL pear bottom flask equipped with a stirring bar. 0.16g of sodium borohydride was then added, and 30 minutes was allowed to elapse. Thin layer chromatography showed the reaction to be complete. The reaction mixture was a white liquid. The mixture was transferred to a beaker and cooled in an ice bath for 10 minutes, then 2mL of 6mL HCl (aq) was added dropwise, resulting in a clear liquid, H2 gas, and a white precipitate. Water dissolved the precipitate, then the product was transferred to a centrifuge tube & the organic layer was extracted with dichloromethane. The mixture was washed with 1. Bauer, Kurt/Garbe, Dorothea; Common Fragrance and Flavor Materials. 1985 2 water and dried by passing it through anhydrous sodium sulfate. Solvent was removed by rotary evaporator. The product was a light yellow liquid, 0.51g. 500 microliters of alpha-methyl-benzyl alcohol, then 5mL of dichloromethane were placed in a 10mL pear bottom flask equipped with a stirring bar. 370 microliters of pyridine were added. 1.42mL acetyl chloride mixed with 1mL dichloromethane was added dropwise over several minutes. Thin layer chromatography showed the reaction to be complete after 30 minutes. A thick, white precipitate formed within the reaction mixture. The mixture was transferred to a beaker and cooled in an ice bath for 10 minutes. Water dissolved the precipitate, then the product was transferred to a centrifuge tube & the organic layer was washed once with 3M hydrochloric acid, twice with distilled water, then twice with saturated sodium carbonate, then twice more with water. The mixture was dried by passing it through anhydrous sodium sulfate. Solvent was removed by rotary evaporator. The product was a clear liquid, 0.45g. Styrene: NMR(CDCl3, 4Hz) 3.89 (s, 1 H); 4.09 (s, 1H); 5.10 (m, 1H); 7.31 (s, 5H). IR (KBr)692.85, 1456.11, 770.12, 3855.42, 3448.44, 3841.15, 3752.70 cm-1. Acetophenone: NMR(CDCl3,) 2.4 (s, 3 H); 7.35(m, 3H); 7.8 (m, 2H);. IR 690.49, 760.04, 1265.62, 1358.99, 1448.43, 1598.43, 1681.73 cm-1. Phenylacetylene: IR 614.47, 628.77, 695.96, 766.60, 887.59, 1213.01, 1488.43. Alpha-methylbenzyl alcohol: IR 698.59, 759.76, 1010.38, 1076.23, 1451.44, 2970.35, 3350.16. NMR(CDCl3) 1.4 (d, 3H); 1.8 (s, 1H); 4.7 (m, 1H); 7.2 (s, 5H). Alpha-methylbenzyl acetate: IR 699.79, 1029.48, 1065.64, 1209.35, 1241.52, 1371.56, 1745.03. NMR(CDCl3) 1.6 (d, 3H); 2.2 (s, 3H); 46.0 (m, 1H); 7.2 (s, 5H). 1. Bauer, Kurt/Garbe, Dorothea; Common Fragrance and Flavor Materials. 1985 3