Spec Data Sheet – AVM System 100 Rev

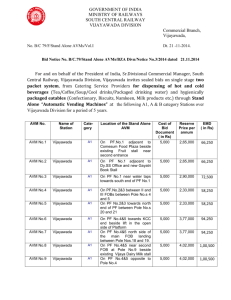

advertisement

SPEC DATA SHEET Sections - 071800 / 071813 Top Coat Sealer 4300 Heavy Duty Single Component Solvent Based Acrylic Sealer Section 071800 / 071813 Fluid Applied Waterproofing Product Name Top Coat Sealer 4300 Manufactured by AVM Industries, Inc. 8245 Remmet Ave, Canoga Park, CA 91304 Tel: 818.888-0050 Fax: 818.888.0050 Website: www.avmindustries.com Product Description AVM Top Coat Sealer 4300 is an extra heavy duty, high performance, single component solvent based acrylic sealer, designed to promote deep penetration and provide long lasting protection to the coated surfaces. AVM Top Coat Sealer 4300 develops outstanding water repellence and has excellent stain, chemical and abrasion resistance properties Advantages: AVM Top Coat Sealer 4300 is a single component brilliant hard film sealer. It is very tough, durable and very easy to clean. It was specifically designed for the harshest, most demanding high pedestrian and vehicular traffic environments. It has low VOCs, is environmentally friendly and harmless to the surrounding surfaces. It will provide excellent protection from oil stains, grease, other common contaminants and freeze-thaw problems. Where to Use Recommended for newly cured or old concrete surfaces, exposed aggregate, acid stain finish sidewalks, driveways, parking garages, and sealing new and existing decks. Warranty AVM standard 1 year warranty applies. Warning Flammable. Keep away from heat, sparks, and flames. Do not smoke. Vapors may ignite explosively. Use in well-ventilated area. Avoid breathing vapors. Wear protective clothing, gloves and safety glasses. Harmful or fatal if swallowed. KEEP OUT OF THE REACH OF CHILDREN Spec Data Sheet – AVM System 100 Rev. 10/2008 AVM Document # 34150 Delivery, Storage, and Handling a. Delivery of the AVM Top Coat Sealer 4300 must be in its original sealed containers, with manufacturer’s name and label intact. b. Handle and store containers and bags in accordance with printed instructions. c. Store at temperatures between 50°F and 90°F. Do not store materials in direct sunlight or where they may be damaged by water or rain. d. Keep all materials out of the reach of children. e. If irritation occurs during use, liberally flush affected areas with water. If irritation continues, see a physician immediately. f. Shelf life is one year form manufacturing date in sealed, unopened containers. Project Conditions a. b. c. d. e. f. g. Substrate temperature must be above 45°F and below 85°F Do not apply in direct sunlight when temperature is above 80°F Provide adequate ventilation during installation Do not apply in highly humid or wet conditions Substrate must be cured and completely dry Do not use where hydrostatic pressure is possible Do not use on glazed ceramic tile, quarry tile, marble, terrazzo, dense brick, dense slate System Application Install the Top Coat Sealer 4300 in accordance with its Installation Instructions. Preparation The substrate surfaces must be structurally sound, clean, dry, fully cured, free of efflorescence, dust, dirt, silicone, oil and other contaminants that would prevent the proper penetration and bonding of the AVM Top Coat Sealer 4300. Joints or cracks should be sealed or filled prior to the application of the AVM Top Coat Sealer 4300. For proper bonding, it is recommended to pressure wash the surfaces scheduled to receive the AVM Top Coat Sealer 4300. For the ultimate bonding, prime first with AVM Epoxy Primer. Installation AVM Top Coat Sealer 4300 should be applied in light, (thin) even coats. For best sealing properties, a minimum of 2 thin coats are recommended. The Sealer can be applied using a brush or a roller using a short or medium nap roller cover. The Sealer can also be applied using low pressure airless spray equipment using a fan type spray tip with orifice size from 0.018 to 0.035 inches. Hold spray tip approximately 12-18 inches from the surface. Do not over apply material. If puddles occur than brush or roll them out. A second coat can be applied after the first coat is dry to the touch (after 1-3 hours) or after 24 hours. (For best results however, 24 hours between coats are recommended) Quality Control a. Visually inspect all coated surfaces to ensure a full and proper coating application, especially at corners, drainage scuppers and hard-to-reach areas. b. All unsatisfactory areas shall be repaired prior to final acceptance.. Spec Data Sheet – AVM System 100 Rev. 10/2008 AVM Document # 34150 Protection of Installed Work The completed section shall be protected from all pedestrian traffic for the first 24 hours after application and until the surface is sufficiently cured. (The amount of drying time may vary depending on temperature and humidity conditions) Typically, light foot traffic may resume after 4-6 hours. Clean Up Clean tools immediately using Xylene or M.E.K. Maintenance Periodic cleaning and maintenance is required. For further information, refer to the Top Coat Sealer 4300 maintenance instructions. Availability and Cost Contact AVM Industries or your approved applicator for pricing and availability. Technical Services Technical services are available by contacting our offices at: 888.414.1041 or 818.888.0050 or visit www.avmindustries.com System Specifications The following coverages are based on controlled tests. Actual coverages may vary. Materials AVM Top Coat Sealer 4300, 1st Coat AVM Top Coat Sealer 4300, 2nd Coat Over Deck Coatings 150-200 sq. ft./gal. 200-300 sq. ft./gal. Over Semi-Smooth Concrete 150-250 sq. ft./gal. 250-350 sq. ft./gal. Over Porous Surfaces 75-100 sq. ft./gal. 100+ sq. ft./gal. Technical Data – AVM Top Coat Sealer 4300 Single component solvent based acrylic sealer Flash Point -40F General Data – AVM Top Coat Sealer 4300 Shelf Life: One year in original unopened packaging. Storage Conditions: Store dry at 50°-90°F. If frozen, discard Packaging Approximate Shipping Weights AVM Top Coat 4300 19/47 lbs. AVM Top Coat 4300 Item/Component 1.0/5.0 gal. pails Packaging 19.0/47.0/lbs Approx Shipping Weights Spec Data Sheet – AVM System 100 Rev. 10/2008 AVM Document # 34150 Under 100 g/L VOC PRECAUTIONS Warnings: FLAMMABLE CONTAINS PETROLEUM DISTILLATE: Keep away from heat, sparks and flame. To avoid breathing vapors or spray mist, open windows and doors or use other means to ensure fresh air entry during application and drying. lf you experience eye watering, headaches or dizziness, increase fresh air or wear respiratory protection (NIOSH/ MSHA TC 23C or equivalent) or leave the area. Close container after each use. Avoid contact with skin. Use With Adequate Ventilation NOTE: Reports have associated repeated and prolonged occupational over-exposure to solvents with permanent brain and nervous system damage. Intentional misuse by deliberately concentrating and inhaling the contents may be harmful or fatal. Keep From Freezing Keep Out Of Reach Of Children Antidotes INGESTION: Do not induce vomiting. Call a physician. EYES: physician. Flush with large amounts of water for 15 minutes, holding eyelids open. If irritation persists see a INHALATION: Remove to fresh air and rest. SKIN: Wash thoroughly with mild soap and water. Health Flammability Reactivity Personal Protection 2 4 0 H For a complete list of details in CAD or PDF, please visit our website at www.avmindustries.com Spec Data Sheet – AVM System 100 Rev. 10/2008 AVM Document # 34150