Northcote Pottery Practical Activity

advertisement

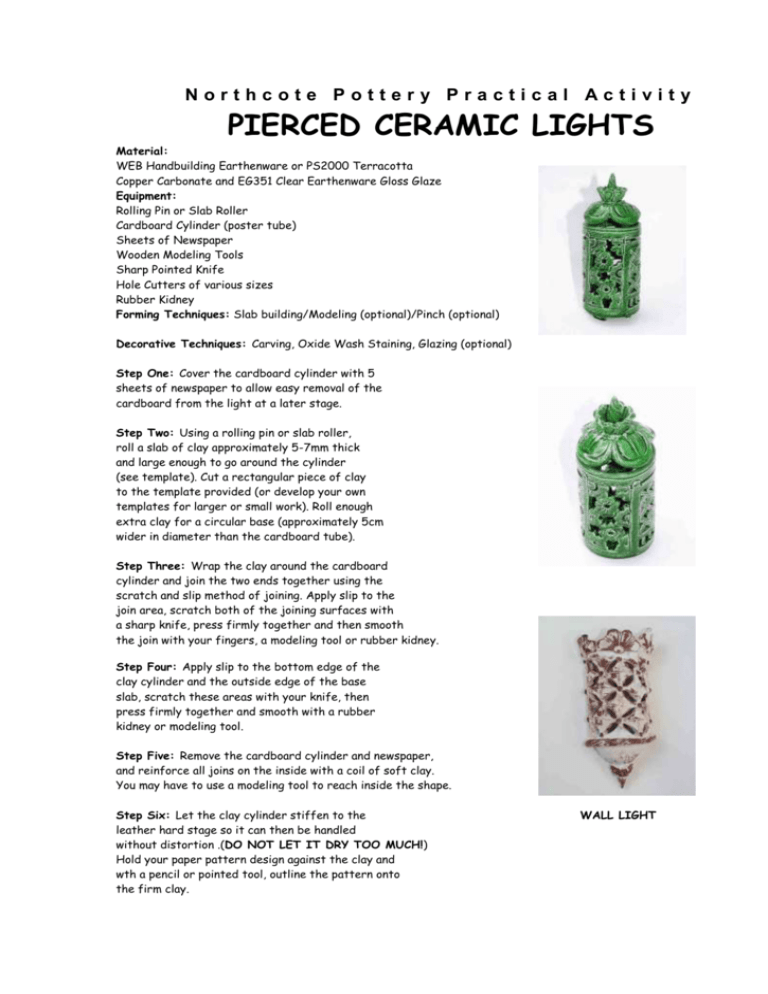

Northcote Pottery Practical Activity PIERCED CERAMIC LIGHTS Material: WEB Handbuilding Earthenware or PS2000 Terracotta Copper Carbonate and EG351 Clear Earthenware Gloss Glaze Equipment: Rolling Pin or Slab Roller Cardboard Cylinder (poster tube) Sheets of Newspaper Wooden Modeling Tools Sharp Pointed Knife Hole Cutters of various sizes Rubber Kidney Forming Techniques: Slab building/Modeling (optional)/Pinch (optional) Decorative Techniques: Carving, Oxide Wash Staining, Glazing (optional) Step One: Cover the cardboard cylinder with 5 sheets of newspaper to allow easy removal of the cardboard from the light at a later stage. Step Two: Using a rolling pin or slab roller, roll a slab of clay approximately 5-7mm thick and large enough to go around the cylinder (see template). Cut a rectangular piece of clay to the template provided (or develop your own templates for larger or small work). Roll enough extra clay for a circular base (approximately 5cm wider in diameter than the cardboard tube). Step Three: Wrap the clay around the cardboard cylinder and join the two ends together using the scratch and slip method of joining. Apply slip to the join area, scratch both of the joining surfaces with a sharp knife, press firmly together and then smooth the join with your fingers, a modeling tool or rubber kidney. Step Four: Apply slip to the bottom edge of the clay cylinder and the outside edge of the base slab, scratch these areas with your knife, then press firmly together and smooth with a rubber kidney or modeling tool. Step Five: Remove the cardboard cylinder and newspaper, and reinforce all joins on the inside with a coil of soft clay. You may have to use a modeling tool to reach inside the shape. Step Six: Let the clay cylinder stiffen to the leather hard stage so it can then be handled without distortion .(DO NOT LET IT DRY TOO MUCH!) Hold your paper pattern design against the clay and wth a pencil or pointed tool, outline the pattern onto the firm clay. WALL LIGHT Kerry Punton 2001 Step Seven: Using a sharp pointed knife, cut the black larger sections of your design out of the cylinder carefully. Scratch or shallow carve additional detail onto the surface (but not through the wall) of the slab cylinder. Lino carving tools are most useful for this. Use various sized hole cutters to cut out regular circular holes, or to create a starting hole for decorative shapes. Step Eight: When the piece is completely dry, paint a copper carbonate and water wash into the low sections of the carving. Lightly sponge off any excess copper carbonate, or if the work is dry, dust it off with a stiff brush. (Wear a particle mask if you are doing this). The copper carbonate should stay in the recessed areas. Do not apply too much wet copper mix to dry pots – excess amounts of wetness will open up joins. Step Nine: When fully dry, once-fire your pierced ceramic light to 1100C – the copper carbonate will turn sepia brown where lightest and metallic black where strongest. Alternately, bisque fire the cylinder to 1000C - 1100C, then apply clear gloss glaze and fire to 1100C. The copper carbonate will give a rich copper green colour. Step Ten: Insert a chunky candle or tea light into your finished work. A wire could be threaded through the top edge of the light to hang it in an outdoor setting or in trees etc. BEWARE THE FIRE HAZZARD THAT UNATTENDED CANDLES CAN CREATE! CUT OUT DESIGN INSPIRATION SOURCES: Mexican tin ware, geometric Islamic mosaic tiles, Arts and Crafts textile designs, early American recycled tin Folk Art, African style dot images, Op Art patterns etc ADDITIONAL HANDBUILDING ACTIVITES: Option 1 Make a lid for your light by using a pinch pot or press moulded pot as the base for modeled features (Islamic dome designs, vegetable forms, character head, architectural form etc). Add a pair of slabs inside the lid which will help locate it on the light, and also hold it in place if the light is moved. Option 2 Invert the light onto a footed platform made from modeled clay legs (3) onto an additional larger slab. Cut additional holes into he top of the light (formerly the base) to create an exotic design. Option 3 Model dramatic handles onto your light which could be applied to either the sides or top edge of the form. Remember to make the handles strong enough (thick enough) to carry the weight of the light. Kerry Punton 2001