FTIR Microspectroscopy

advertisement

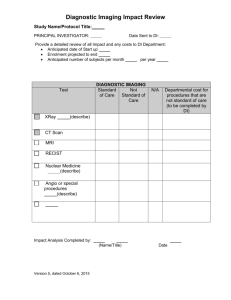

FTIR Microspectroscopy Fourier Transform Infrared Spectroscopy is a workhorse of the industrial materials testing division. The combination of a microscope with an infrared spectrometer results in a powerful instrument that allows for the detection of chemical species from a specific spatial region. Combining spatial specificity with information on its chemical constitution, a chemical species map may be constructed for the whole spatial area. This typically involves collecting the IR spectrum of the sample at a point, moving the sample to another location and collecting the spectrum at the second point ans so on. In this manner, the whole area is mapped point-by-point. The Concept of FTIR Imaging The state of the art in FTIR microspectroscopic instrumentation today is the combination of a Focal Plane Array (FPA) detector with a step-scan spectrometer. This configuration allows for the imaging of a wide field of view in a single collection. The concept of imaging using an FPA is illustrated with a typical example in the figure below. The beam of a step-scan spectrometer is diverted through standard microscope optics with the FPA at the end of the optical train. The premise behind the imaging experiment is that each pixel on the FPA corresponds to a unique spatial region on the sample. The time required to collect a spectrum for a single pixel is the time required to collect the whole image. Multiple channels of information are simultaneously collected (the multi-channel advantage). Imaging Vs. Mapping As opposed to image build-up by point-by-point FTIR mapping, FTIR imaging is used to describe the collection of a chemical profile of the sample area in a single experiment. The major instrumental difference between a mapping and an imaging instrument is the incorporation of a Focal Plane Array detector at the end of the optical train in the microscope. Average chemical information (i.e. the infrared spectrum) of a specific spatial area on the sample can be uniquely correlated to the output of a pixel in the FPA. Hence, no apertures are required to limit the sample area examined. Moreover, the sample does not need to be moved as a given field of view is imaged in a single collection experiment. It may be immediately seen that the collection time is decreased by a factor of n2, where n is the number of spatial resolution elements in one direction of a square sample area imaged (n is the number of steps in a mapping experiment considered equivalent to a pixel in the imaging experiment). Moreover, the practical spatial resolution limit in the mapping technique is close to 10 microns. For imaging, the resolution is essentially wavelength limited. Hence, the imaging technique has allowed for the collection of images in faster time with higher resolution. Some phenomena have also been examined in real time using FTIR imaging. More details can be found in the applications section. FTIR Imaging Spectrometry Instrumentation: The Bio-Rad Stingray imaging spectrometer was used to acquire infrared images. It consists of a step scan interferometer bench (FTS 6000) coupled to a Focal Plane Array (FPA) detector equipped microscope, UMA-500. The microscope detector is a Mercury Cadmium Telluride (MCT) array of 64 x 64 elements imaging an average spatial area of 500 micron x 500 micron in a single experiment. A ZnSe lens is used to focus the sample area onto the FPA. To improve signal to noise characteristics, the instrument is equipped with a Germanium long pass filter and KRS-5 plate, which acts as a diffuser. The long pass filter serves to prevent detector pixel saturation and removes background noise outside the bandwidth of interest. The lightly sanded KRS-5 plate is placed in the beam path before the condenser to further improve spatial homogeneity in the camera field of view and prevent the detector elements in the center of the array from saturating. The diffuser was not required for the sample single beams as the dispersed liquid droplets scattered light and reduced the maximum flux. Image Collection Parameters: Stepping rates of 10 Hz, 5 Hz, 2.5 Hz and 1 Hz have generally been used with co-added frames being 3, 20, 80, and 200 respectively at a rate of frames per second for each image. The integration time per frame was set to 0.0931 ms. A stepping rate of 25 Hz did not give reliable performance of the spectrometer and co-adding more than 3 frames at 10 Hz lead to the same problem. A total of 4096 single beam images were obtained in each experiment after fast fourier transforming the interferograms collected at an undersampling ratio (UDR) of 4 and spectral resolutions of 8 cm-1 or 4 cm-1. These are typical collection parameters for our samples on our instrument and will, in general, vary with the samples and results desired on others. Data Processing and Noise Reduction Data Processing: One of the major differences between IR imaging and conventional FTIR microspectroscopy is the large amount of data generated in a single imaging experiment. 4096 (for a 64x64 array) to 65536 (for a 256x256 array) spectra acquired in a single experiment are common numbers. Special data handling techniques and software are required for data analysis. Image acquisition and preliminary processing is carried out using the instrumental software, Win-IR Pro. A hyperspectral imaging software package, the Environment for Visualizing Images (ENVI), was used for further processing the image cube. Custom routines for mathematical manipulations, baseline correction, and noise estimation were written in IDL and incorporated into ENVI. Morphological analyses were carried out using a commercial image analysis software package, Sigma Scan Pro. All spectral image computations are performed on a relatively fast Windows NT desktop computer (450 MHz Pentium III processor/ 128 MB RAM) optimized for running ENVI. Image analysis using Sigma Scan Pro was carried out on a slower computer (133 MHz/32 MB RAM) running Windows 95. Improving Image quality Introduction The Signal to Noise Ratio (SNR) achieved in FTIR Imaging data varies considerably with the data collection parameters. In general, the SNR levels for spectra collected using the step scan mode are lower compared to spectra collected in the rapid scan mode. Moreover, the FPA has its own unique sources of noise. A number of factors affecting the SNR of spectra obtained in the imaging experiment are discussed in the section below. Sources of Noise The sources of noise are varied and may be broadly categorized based on their origin. The noise sources are 1. Detector Noise 2. Spectrometer Noise: Sources of noise in a step scan FTIR spectrometer have been a source of discussion in the literature. An excellent article has been published describing the commonly encountered sources of noise (Manning C.J., and Griffiths P.R., Appl. Spectrosc., 1997, 51, 1092). 2. The sample: The sample introduces it's own means of lowering the SNR in many cases. Since the very reason to use FTIR imaging is to examine multiphase structures, there is a natural existence of variations in refractive index and transparency across the spatial area examined. The sample is the most difficult noise source to characterize. Noise Reduction by Hardware Improvement Clearly, one route to lower noise data is to have lower noise FPA detectors, i.e. detectors with lower noise electronics, more efficient photon response, and deeper wells etc. However, expecting such dramatic improvements every small interval of time is not a realistic situation. A situation where the detector may need to be replaced is when pixels start "dropping off". Actually, delamination of the IR sensitive material from the underlying array detector takes place due to the failure of bump bonds between the two. This leads to non-responsive pixels showing up as black pixels during data collection. In our experience, the array remains stable for months with the number of such pixels being less than a fraction of a percentage point. Once failure sets in, the FPA is still in a satisfactory state with less than a few percent of failed pixels for many months thereafter. Depending on the tolerance levels of the experiment, catastrophic failure (say greater than 10% failed pixels) may not occur till months after the first signs of failure. Oddly, the pixels start to fail from the outside corners first! Noise Reduction by Collection Techniques The simplest technique in this category is to increase the number of frames co-added. However, the benefits of this technique, especially when considering increase in collection time, are limited. A typical curve showing the SNR as a function of holding time at each mirror step is shown in the figure below. The figures next to the data points show the number of coadded frames. Clearly, coadding more than 80 frames has little impact on the SNR. In most cases, the optimum number of frames to be co-added are 20. For a spectral resolution of 8cm-1 and a UDR setting of 4, a collection time of approximately 3.5 minutes is achieved for 20 co-added frames. A collection technique was suggested by Snively and Koenig to increase the image SNR. This was similar to classical co-addition in that absorbance image files were co-added. The improvement is the SNR was found to scale as (n)1/2 where n are the number of absorbance image files co-added. Clearly, the time required to attain higher SNR images exceeds the benefits by a factor of (n)1/2. An example of the effectiveness of this method can be seen in the figure below When faster events are required to be monitored, such an approach is not very effective as it is time-consuming. Another approach to obtain less noisy data is to co-add pixels that are assumed to have the same true values based on physical arguments. e.g. a column of pixels in the contact method experiments should have the same spectral features. The SNR improvement again scales as (n)1/2 where n are the number of pixels co-added. Post-Collection Noise Reduction This is achieved by using mathematical procedures to eliminate noise. One such procedure is employed by using the Minimum Noise Fraction transform. Details on the application of this transform to reduce noise in FTIR spectroscopic images can be found here. Some applications The coupling of an FTIR spectrometer with an FPA was pioneered by researchers at the Laboratory of Chemical Physics, NIDDK at NIH. Dr. E. Neil Lewis and Dr. I. W. Levin from the NIH, in collaboration with Researchers from the Miami Valley Laboratories at Procter and Gamble: Drs. C. Marcott, R.C. Reeder, A.E. Dowery, G.M. Story and Dr. P.J. Treado from ChemIcon Inc. published a groundbreaking paper using this technique (Anal. Chem., 67, 3377 (1995) ). Researchers and developers at Bio-Rad have developed the concept into a commercial product by combining a state of the art spectrometer bench, the FTS 6000 featuring the 896 interferometer design, with their UMA 500 microscope accessory. Another organization, Spectral Dimensions, has started to manufacture FTIR imaging systems. The spectroscopy laboratories at CWRU, directed by Prof. Koenig, were among the first ones to obtain this instrument and have applied it to study polymeric systems over the last 2+ years. All the work reported on these pages is a product of these laboratories. There are other active groups with numerous publications on the applications of this type of imaging spectrometry. The group at NIH (headed by Dr. Levin) concentrates on the biological aspects of the applications of FTIR imaging. The group at P&G (notably Dr. C. Marcott) have examined polymer laminate films, wheat grains and biological specimens. Other researchers imaging biological specimens include Dr. Treado of Chem Icon Inc. Chris Snively, who did his doctoral work in our group, is now looking at the applications of FTIR imaging to the field of combinatorial chemistry at Purdue. Dr. Norman Wright and co-workers at Bio-Rad are actively involved in the dissemination of Stingray technology : in the design as well as some application aspects. The work of these researchers may be found in many conference presentations and articles (a small list is available here). A search on these researchers using a good database over the last 5-6 years should reveal a large majority of the published/presented literature on FTIR imaging spectroscopy using an FPA. Only some representative examples from my Ph.D. thesis work are reported on these pages. Please refer to the actual publications or request a copy from us for complete details. Please feel free to send email suggesting links to imaging sites and other work. If you would like to contribute some text or images to the site, please send it to me via email. The Analytical Instruments business segment travels from Silicon Valley to the world’s Information Superhighway. In 1999, each of our Divisions, on its own particular road, reached important destinations. In the Semiconductor Measurements Division, market recovery and a number of important new product introductions resulted in substantial revenue and operating income growth. We successfully negotiated the external challenges of 1998, and went on to introduce versions of overlay and film thickness tools that accommodate the new 300mm semiconductor wafer size, capturing large and important new customers. Bio-Rad is also well positioned in the compound semiconductor market with a family of characterization products, such as the RPM 2000 Rapid Photoluminescence Mapper,™ which provide information critical to improving manufacturing productivity. The Company has also introduced scatterometry, a ground breaking new methodology used in process control of semiconductor device manufacturing. Bio-Rad took a new direction in 1999 in spectroscopy by introducing the PharmalyzIR™ instrument, which is tailored to meet the demands of the pharmaceutical industry. The Company also gained momentum with its FTS Stingray 6000™ FT-IR chemical imaging system, an innovative system that generates high-contrast spectral images that help researchers analyze chemical phenomena. The market is expanding, with increased activity in research fields ranging from osteoporosis testing and polymer analysis to agricultural genetic engineering. On the Information Superhighway, Bio-Rad’s Sadtler Division is a world leader in analytical informatics. We offer the largest collection of IR spectra (graphic representations) of natural and commercial compounds, and are constantly improving and expanding the product portfolio. With Bio-Rad’s databases and accompanying software, analytical chemists can easily and quickly compare their spectra with comprehensive spectral databases for accurate identification. Semiconductor wafers are analyzed early in the manufacturing process by the RPM 2000 Rapid Photoluminescence Mapper.™ Vital product characteristics can be identified long before final production costs are incurred. Using Bio-Rad’s Stingray™ FT-IR imaging spectrometer, researchers can view a “pseudo-color” image of onion cells that reveals the distribution of specific chemical species in the sample. Presenting data in this pictorial form permits analysis in minutes rather than hours, improving economy and productivity. Bio-Rad’s SiPHER™ instrument is a unique tool in the semiconductor manufacturing industry. Using a patented optical configuration, the SiPHER™ instrument creates images of electrically active defects in silicon wafers, helping to assure product quality and consistency.