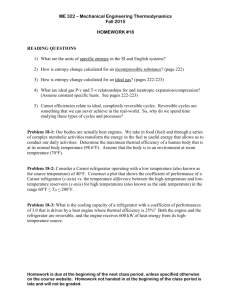

Solving Thermodynamics Problems

advertisement

Solving Thermodynamics Problems – Part II (Entropy) This is a follow on to the previous problem solving notes posted previously. These notes are focused on the additional analysis tools afforded by the 2nd law. Keywords that will imply a 2nd law solution (although it does not guarantee a 2nd law analysis is needed) are: “minimum”, “maximum”, “ideal”, “reversible”, component “’s”, cycle efficiencies, cycle COP’s, “isentropic”, etc. In general, the 2nd law will be involved with problems that have a defined path, but one of the end states is not readily known and not all the heat or work interactions are known. The solution process should follow the same steps from the previous notes, except you now have the entropy balance that can be applied along with the mass balance and the energy balance. The entropy balance is: Q j ds m m isi m ese s gen dt Tj for an open system, and: s Qj m s gen Tj for a closed system. In addition to the entropy balance expressions above, 2nd law analysis brings with it many new definitions/principles and substance models for finding entropy. See the catalogs in the appendix for ways to find entropy, definitions of cycle metrics, definitions of component metrics, and definitions of some cycles. 2nd Law Principles Clausius Statement: Heat can only flow from hot to cold. Kelvin-Planck Statement: A heat engine must exchange heat with at least 2 thermal reservoirs of different temperatures. Clausius Inequality Q j Tj 0 cycle The limiting case of 0 is for a reversible process. Definition of Entropy: Q dS T rev Gary L. Solbrekken ME3324, Fall 2002 10/01/02 For a Real Process with Irreversibilities: Q dS Sgen T where: Sgen > 0 possible, irreversible process Sgen = 0 limiting, reversible process Sgen < 0 impossible process Note: Sgen is ALWAYS your metric to determine if a process is possible or not! Air Standard Assumptions: 1) working fluid is air that can be treated as an ideal gas 2) all processes are internally reversible 3) combustion processes are modeled as heat addition processes 4) exhaust processes are modeled as heat rejection processes Other Useful Definitions: Pressure ratio: Compression ratio: Gary L. Solbrekken rp = p2/p1 (usually used for open system processes) r = Vmax/Vmin (usually used for closed system processes) ME3324, Fall 2002 10/01/02 Appendix This appendix contains a series of catalogs for common parameters that are needed in solving thermodynamics problems. The lists are not intended to be exhaustive, nor is the information contained in the catalogs complete. For a complete discussion of a particular entry, a reference from the Cengel and Turner (C&T) book is included with the chapter and section identified. Note that the symbols used take on the context of the problem. Again, the user should consult C&T for details. Catalog of Cycle Metrics - Real Cycle Type Heat Engine (C & T ch 6.4) Metric W W Q net net 1 out Qin Qin Qin Q Q Qcold COPR cold cold W W Q Q th Refrigerator (C & T ch 6.5) in Heat Pump (C & T ch 6.5) COPHP in hot cold Q hot Q Q hot hot Win W Q hot Qcold in Catalog of Cycle Metrics – Ideal/Carnot Cycle Type Heat Engine (C & T ch 6.11) Metric th,Carnot 1 Tcold Thot Refrigerator (C & T ch 6.12) COPR ,Carnot Tcold Thot Tcold Heat Pump (C & T ch 6.12) COPHP,Carnot Thot Thot Tcold Note: All temperatures must be absolute Catalog of Component Metrics Device Nozzle (C&T ch 7.12) Turbine (C&T ch 7.12) Compressor Pump (C&T ch 7.12) Regenerator (C&T ch 8.8) Gary L. Solbrekken Device Metric nozzle 2 actual V 2 adiabatic, rev V turb,ad ,rev Wactual W actual Wadiabatic,rev W adiabatic, rev comp / pump ,ad ,rev regen Wadiabatic,rev Wactual W adiabatic, rev W actual Q actual Q max ME3324, Fall 2002 10/01/02 Catalog of Substance Models Substance Model Application Domain Characteristics Property Tables – solid, Whenever experimental Real data, so this is ideal as liquid, vapor (C&T ch 7.3 data is available for long as the experimental and ch 7.7) substance of interest conditions used to make table are broadly applicable to the application. Can also use Tds eqns. Tds = du + pdv Tds = dh + vdp Incompressible – liquid Most liquids and processes Properties are approximated (C&T ch 7.8) where volume expansion is by the saturated liquid not of interest (an example properties at the system of a mis-application would temperature. Specific heats be a natural convection are temperature dependent process) only. s(T,p) sf(T) s = ∫C(T)dT/T Cavln(T2/T1) Incompressible (C&T ch 7.8) – solid Most solids and processes where volume expansion is not of interest (an example of a mis-application would be a deformation/bar expansion process) Ideal Gas (C & T ch 7.9) Special case vapor where PR (P/Pcrit) is nearly 0. Specific heats are temperature dependent only. s = ∫C(T)dT/T Cavln(T2/T1) Allows use of ideal gas equation of state, PV = mRT. When combined with Tds eqns and fact that specific heats are a function of temperature only, the following 2 forms arise: s = ∫Cv(T)dT/T + Rln(v2/v1) Cv,avln(T2/T1) + Rln(v2/v1) s = ∫Cp(T)dT/T - Rln(p2/p1) Cp,avln(T2/T1) - R ln(p2/p1) Ideal Gas – special case of Special cases of entropy isentropic process (C & T change when the device of ch 7.9) interest executes a process that is adiabatic and reversible in nature. Gary L. Solbrekken ME3324, Fall 2002 The following arise when s from above is set to 0 and manipulated. Variable specific heats: (p2/p1)|s=Pr2/Pr1=f(T2)/f(T1) (v2/v1)|s=vr2/vr1=f(T2)/f(T1) Constant specific heats: (T2/T1)|s = (v1/v2)k-1 (T2/T1)|s = (p1/p2)(k-1)/k (p2/p1)|s = (v1/v2)k 10/01/02 Catalog of Cycles Otto Cycle (C&T ch 8.5): - uses air standard assumption - air in piston/cylinder assembly is modeled as a closed system Process Step 1–2 2–3 3–4 4–1 Process description Adiabatic, reversible, compression Constant volume heat addition with piston at TDC Adiabatic, reversible, expansion Constant volume heat rejection with piston at BDC Brayton Cycle (C&T ch 8.7 – 8.8) - uses air standard assumption - air through engine is modeled as an open system - can be modified with component ’s and regeneration Process Step 1–2 2–3 3–4 4–1 Process description Adiabatic, reversible, compression (compressor) Constant pressure heat addition (combustor) Adiabatic, reversible, expansion (turbine) Constant pressure heat rejection (exhaust/heat exchanger) Rankine Cycle (C&T ch 8.10 – 8.13) - uses water as working fluid - water through engine is modeled as an open system - can be modified with component ’s and reheat Process Step 1–2 2–3 3–4 4–1 Process description Adiabatic, reversible, compression (pump, state 1 is sat liq) Constant pressure heat addition (boiler) Adiabatic, reversible, expansion (turbine) Constant pressure heat rejection (condenser) Vapor-Compression Refrigeration Cycle (C&T ch 8.16 – 8.17 - uses refrigerant as working fluid - refrigerant through engine is modeled as an open system - can be modified with component ’s Process Step 1–2 2–3 3–4 4–1 Gary L. Solbrekken Process description Adiabatic, reversible, compression (compressor, state 1 is sat vapor) Constant pressure heat rejection (condenser) Constant enthalpy expansion (expansion valve, state 3 is sat liq) Constant pressure heat absorption (evaporator) ME3324, Fall 2002 10/01/02