b. Preparation of silver nanoparticles

advertisement

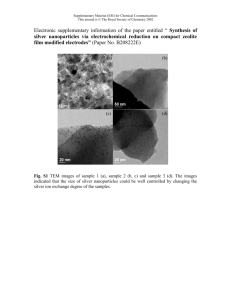

Preparation and characterization of stable dispersed and hydrophobic silver nanoparticles Dan Li * Department of Chemistry and Chemical Engineering, Weifang University, Weifang, China E-mail: danli830109@163.com Abstract—The were medium. Oleic acid is used as surface coating reagent and successfully fabricated by stabilization in the mixed system of alkylamines as solvent. The effects of n-butylamine or water, alkylamine and oleic acid and reduction with hydrazine cyclohexylamine in the reaction solvents for the morphology hydrate solution. The surface coated silver nanoparticles can and composition of prepared silver nanoparticles were stably disperse in nonpolar solvent such as alkane, chloroform or investigated. The silver nanoparticles dispersed well in kerosene and form a silver colloid. The effects of n-butylamine or nonpolar solvent formed silver colloid. The thermal stability cyclohexylamine in the reaction solvents for the morphology and of the silver colloids was invesgatied by monitored their composition of prepared silver nanoparticles were investigated. Uv-vis spectra changing. hydrophobic silver nanoparticles Keywords: silver nanoparticles; hydrophobic; alkylamine 1. INTRODUCTION 2. EXPERIMENTS a. The increased interest in small clusters of metal particles is related to the unique properties exhibited by these systems which are the result of their size, high surface area and exceptional surface activity providing excellent catalytic, and optical properties. Silver nanoparticle based colloids or nanofluids were studied after they were found to have Materials All chemicals used were of analytical grade, obtained commercially and used without further purification. Silver nitrate was supplied by Shanghai Chemical Corporation, China. Oleic acid, n-butylamine, cyclohexylamine, ethanol, and hydrazine hydrate solution were purchased from Sinopharm Chemical Reagent Co., Ltd., Shanghai, China. significantly higher thermal conductivities. Recently, the effects were not just focused on the water based nanofluids, b. Preparation of silver nanoparticles and more and more studies have been focused on preparation The hydrophobic silver nanoparticles with well dispersion and evaluation of oil based nanofluids. Transformer oil, were prepared by reducing AgNO3 with hydrazine hydrate mineral oil, silicon oil, and some organic solution are used as solution at 80 °C). In a typical synthesis, 20 mL 0.05 M the base fluid for studying nanofluids. [1-5] However, metal AgNO3 solution was mixed with a solution of oleic acid (2.0 g, nanoparticles tend to form agglomerates because of strong as a surface modifie) and amine (10 mL) with stirring at a interparticle interactions, often leading to precipitation of the temperature. The pH of solution was maintained at about particles in the fluid phase. [6, 7] Therefore, a challenge of 11~12. Excess hydrazine hydrate solution was added to the nanofluids is to produce well-dispersed, stable oil based mixture. The color of the reaction mixture turned red and nanofluids with a feasible method. It is strongly needed that eventually brown. The reaction was allowed to proceed at the the metal particles have well dispersible in oil and nonpolar last temperature for 0.5 h with continuous stirring. The medium. reaction mixtures were left to cool down and stayed at room This work provides a method to prepare hydrophobic silver temperature. After cooling, the mixtures were separated from nanoparticles with oleic acid coating in different alkylamine the brown reaction mixture by centrifugation at 8000 rpm and washed three times with excessive ethanol, and finally were morphology are significant. In this process, oleic acid was dried in a vacuum oven at 40 °C. The powders were obtained. used to coat the surface of the silver nanoparticles due to the c. Measurements weak coordination, so the prepared silver nanoparticles were oil soluble. Oleic acid has also been extensively used in this The transmission electron micrographs (TEM) were obtained by employing HRTEM CM-200 (PHILIPS, USA) instrument using an operating voltage of 160 kV. UV-vis spectroscopy measurements (200-700 nm) were performed using a UV-2550 spectrophotometer (Shimadzu, Japan) equipped with 1.0 cm quartz cells at 25 C. The X-ray diffraction patterns of Ag nanoparticles were recorded by employing a Bruker D8 Advance X-ray diffractometer (Bruker, Germany) with monochromatized Cu Kα radiation (λ=1.5405 Å). The differential scanning calorimeter (DSC/TG, NETZSCH STA 409 PC/PG) was used to analyze the thermal decomposition process of the particles with a heating rate of 10 K min-1 in N2 with a flow rate of 20 ml/min. The metal content of silver nanoparticles was determined by TG analysis. process as the surfactant to control the growth of metal particles and prevent their agglomeration. Thus the silver core growth was not effectively suppressed by oleic acid in the cyclohexylamine solution. The structure of cyclohexylamine in reaction system affected oleic acid coating on the surface of the silver nanoparticles. XRD was employed to examine the crystalline structures of the as-prepared silver particles, as shown in Fig. 2. For all the samples, the X-ray diffraction peaks can be well assigned to the (111), (200), (220) and (311) crystallographic planes of face-centered cubic (FCC) silver crystals, respectively. The metal contents of silver nanoparticles were determined by TG analysis. The metal contents of silver nanoparticles prepared in n-butylamine solution or cyclohexylamine solution are 74 % and 93 % respectively, and the residual part is organic 3. RESULTS AND DISCUSSION Butylamine and cyclohexylamine were used as a surfactant for stabilizing Ag+ and oleic acid in the reaction system of coexisting aqueous phase. Oleic acid was used for coating the surface of the silver nanoparticles, which make the silver nanoparticles are oil soluble. stabilizer coating on the surface of the silver core. The metal contents of coating layer coating on the surface of the silver were affected by the reaction system, and the oleic acids content coated on the silver nanoparticles prepared in cyclohexylamine solution was significantly lower than those prepared in n-butylamine solution. The prepared silver nanoparticles can be separated from the reaction medium and stable for storing. Temperature has a significant effect on the rate of reduction reaction. The silver nanopartiles were prepared at different temperatures. Samples for the TEM examination were prepared by dissolving solid samples in dichloromethane or chloroform. One or two drops of the sample solution were allowed to dry on a copper grid coated with carbon film. Fig. 1 shows typical TEM images and the corresponding size distribution of silver nanoparticle obtained at different solvents. Fig. 1a showed spherical and small nanoparticles which were prepared in n-butylamine and oleic acid solution. The growth of silver particles is effectively limited to an average size of 11~15 nm by the well stabilization of oleic acids. Fig. 1b shows silver nanoparticles prepared in the cyclohexylamin solution without uniform morphology. Therefore, the influence of the different alkylamine in the reaction system on the particle size and b Figure 1. TEM images of silver nanoparticles synthesized in different Figure 4. UV-vis spectra of the as-prepared silver nanoparticles synthesized alkylamine solutions: (a) butylamine; (b) cyclohexylamine. in different solvents: (a) butylamine; (b) cyclohexylamine. The solution for UV-vis measurement was obtained by dispersing the silver nanoparticles in n-heptane. They have the b characteristic absorption with maxima at 410~420 nm for the silver plasmon band similar to the literature values as shown Intensity in Fig. 4. The silver nanoparticle prepared in the mixture of oleic acid and n-butylamine redissolved in n-heptane showed a [110] the λmax value of absorption at 410 nm (curve a). The other [200] silver [311] [220] nanoparticles prepared in oleic acid and cyclohexylamine (curve b) show two absorption bands at 430 30 40 50 60 70 80 90 and 540 nm respectively, which is characteristic for increase of the size. The peaks at 410 nm are conventional plasmon 2/ band for nearly spherical silver particles. However, compared Figure 2. XRD patterns of silver nanoplates prepared in different alkylamine with a, the band b is more broadened and the relative intensity solutions: (a) butylamine; (b) cyclohexylamine. of the plasma peak is reduced. The absorption peak of the prepared silver nanoparticles in cyclohexylamine solution appears red shifted and broadened. It is resulted from different shape nanoparticles mixed in Fig.1b. The difference in the 100 shape of the plasma band suggested the change in particle size b 95 under different laser wavelengths. The λmax values of these TG/% 90 plasmon absorptions are different from the others because the 85 plasmon absorptions of nanoparticles rely on the particle size and morphologies [8-10]. 80 a 75 70 100 200 300 400 T/C 15 alkylamine solutions: (a) butylamine; (b) cyclohexylamine. 2.0 Thermal stability time/h Figure 3. TG curves of the silver nanoparticles prepared in different 10 5 1.5 Abs. 0 110 b 1.0 120 130 140 150 160 Temperature/C Figure 6. Thermal stability time of the silver-heptane colloids at different 0.5 temperatures. a 0.0 300 400 500 /nm 600 700 The UV-vis spectral analysis was used to monitor the thermal stability of silver prepared in a mixture of oleic acid and n-butylamine. The silver nanoparticles dispersed in n-heptane were stable at room temperature for months, and no detectable deposits could be found. It follows that the hydrophobic layers of oleic acid outside the silver cores truly protect the particles from oxidation and agglomeration. To further investigate the thermal stabilities of the silver nanofluids, samples of 0.1 mass % silver nanoparticles prepared at 80 °C with n-heptane as the base fluid were prepared and monitored in the temperature range of 120-160 °C. The silver nanofluids were kept in an 50 mL Teflon-lined stainless steel autoclave, sealed tightly, and thermostatted at a certain temperature. The nanosilver colloids were considered to be stable when the absorption value of the maxima (λmax) at 418 nm did not show a visible change or red-shift and the colloids were uniform without changing their appearances. It indicated that the silver colloids were instable when the absorption value decreased suddenly. Fig. 6 reports the thermal stability times of the silver colloids as a function of temperature. The silver colloids were stable with different time limits at high temperatures. It is shown that the silver nanofluid had a stable time of 15 h at 120 °C. 4. CONCLUSIONS Hydrophobic silver nanoparticles surface-coated with oleic acid were prepared in different in this work. Oleic acid as surface coating reagent was essential for the production of stable and small scale silver nanoparticles. n-butylamine and cyclohexylamine were used for keeping the reaction medium in one phase, respectively. Addition of n-butylamine and cyclohexylamine had different effects on the morphology and size of the silver nanoparticles. And the content of the organic coating layer was also affected, which was reduced with increasing temperature. All the analyses demonstrated that n-butylamine was better than cyclohexylamine for adding in the reaction system to prepare surface-coated silver nanoparticles. The thermal stability of surface-coated silver prepared in n-butylamine solution was monitored by UV-vis spectral analysis. The prepared silver nanoparticles dispersed in heptane were stable with different time limits at high temperatures REFERENCE [1] Y. Xuan, Q. Li, Heat transfer enhancement of nanofuids, International Journal of Heat and Fluid Flow 2000, 21, 58-64. [2] R. A. Yetter, G.A. Risha, S. F. Son, Metal particle combustion and nanotechnology, Proceedings of the Combustion Institute 2009, 32, 1819-1838. [3] H. E. Patel, S. K. Das, T. Sundararajan, A. S. Nair, B. George, T. Pradeep. Thermal conductivities of naked and monolayer protected metal nanoparticle based nanofluids: Manifestation of anomalous enhancement and chemical effects, APPLIED PHYSICS LETTERS 2003, 83, 14, 2931-2933. [4] X. Wang, A. S. Mujumdar. Heat transfer characteristics of nanofluids: a review. International Journal of Thermal Sciences 2007, 46, 1-19 [5] W. Yu, D. M. France, J. L. Routbort, S. U. S Choi. Review and Comparison of Nanofluid Thermal Conductivity and Heat Transfer Enhancements. Heat Transfer Eng. 2008, 29, 432-460. [6] C. Choi, H. S. Yoo, J. M. Oh. Preparation and heat transfer properties of nanoparticle-in-transformer oil dispersions as advanced energy-efficient coolants. Curr. Appl. Phys. 2008, 8, 710-712. [7] I. Sondi, D. V. Goia, E. Matijević, Preparation of highly concentrated stable dispersions of uniform silver nanoparticles, Journal of Colloid and Interface Science 2003, 260, 75-81. [8] M. V. Roldán, L. B. Scaffardi, O. de Sanctis, Nora Pellegri. Optical properties and extinction spectroscopy to characterize the synthesis of amine capped silver nanoparticles. Materials Chemistry and Physics 2008, 112, 984-990. [9] G. Lee, S. Shin, Y. Kim, S. Oh, Preparation of silver nanorods through the control of temperature and pH of reaction medium, Materials Chemistry and Physics, 2004, 84, 197-204. [10] S. Link, M.A. El-Sayed, Spectral Properties and Relaxation Dynamics of Surface Plasmon Electronic Oscillations in Gold and Silver Nanodots and Nanorods, J. Phys. Chem. B 1999, 103, 8410-8426.