formulae sheet

advertisement

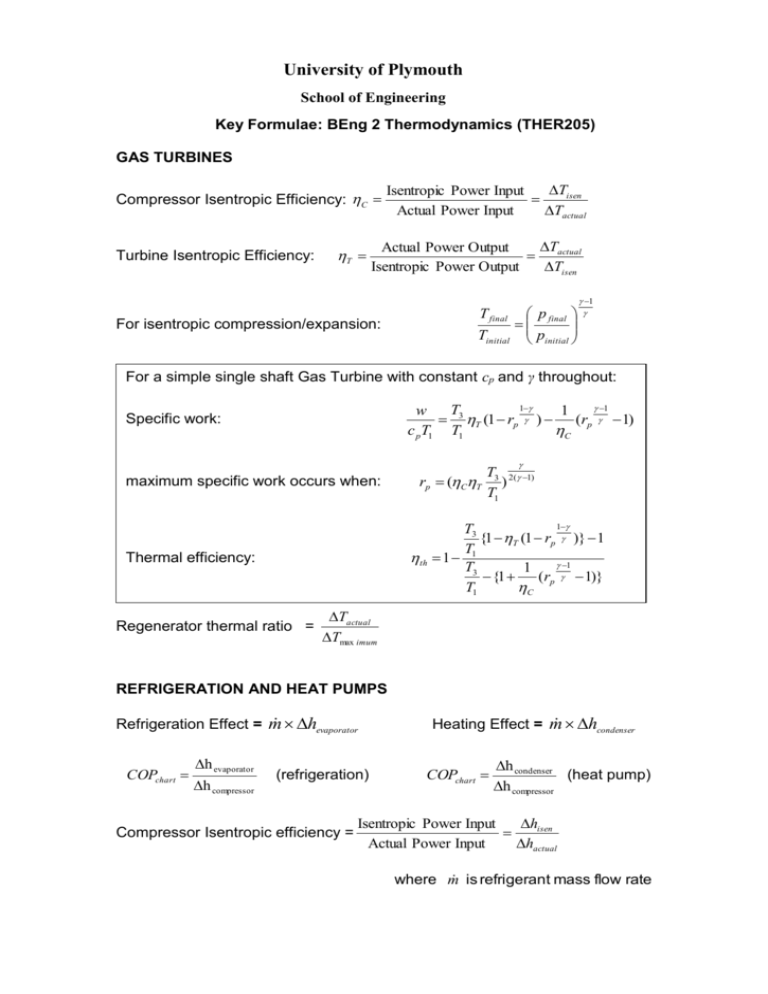

University of Plymouth

School of Engineering

Key Formulae: BEng 2 Thermodynamics (THER205)

GAS TURBINES

Compressor Isentropic Efficiency: C

Turbine Isentropic Efficiency:

T

Tisen

Isentropic Power Input

Actual Power Input

Tactual

T

Actual Power Output

actual

Isentropic Power Output

Tisen

For isentropic compression/expansion:

T final

Tinitial

p final

pinitial

1

For a simple single shaft Gas Turbine with constant cp and γ throughout:

1

1

T

w

1

3 T (1 rp ) (rp 1)

c pT1 T1

C

Specific work:

maximum specific work occurs when:

rp (CT

T3 2( 1)

)

T1

1

T3

{1 T (1 rp )} 1

T

th 1 1

1

T3

1

{1

(rp 1)}

T1

C

Thermal efficiency:

Regenerator thermal ratio =

Tactual

Tmax imum

REFRIGERATION AND HEAT PUMPS

hevaporator

Refrigeration Effect = m

COPchart

h evaporator

h compressor

(refrigeration)

Compressor Isentropic efficiency =

hcondenser

Heating Effect = m

COPchart

h condenser

(heat pump)

h compressor

hisen

Isentropic Power Input

Actual Power Input

hactual

where m is refrigerant mass flow rate

RECIPROCATING COMPRESSORS

Vclearance 1

r p n 1

Vswept

n 1

n

p inletVinduced (r p n 1)

n 1

Volumetric efficiency:

vol 1

Net Indicated Work per cycle:

Wnet

Stage pressure ratio for minimum work:

1

rp R p N

where Rp= overall pressure ratio, and N is the number of stages

ENERGY EFFICIENCY

Energy Conversion Efficiency =

Net (useful ) EnergyOutput

GrossEnergyInput

Annual heating cost for a heating plant:

24Q np

where

16.5 heat

Q design heat load (kW )

n number of degree days

p fuel cost(£/kWh )

heat average heating efficiency

STEADY STATE CONDUCTION

T

plane

Q

x

2T

Q

r

ln o

ri

2-D steady: at an internal node: T0=(T1+T2+T3+T4)/4

1-D steady:

on boundaries: isothermal

insulated (or symmetry)

cylindrical

Tw = const

Tw-1 = Tw+1

convective (plane surface)

T0 = (T1/2+T2+T3/2+BTf)/(2+B)

convective (external corner)

T0 = (T1/2+ T3/2+BTf)/(1+B)

convective (internal corner)

T0 = (T1/2+T2/2+T3+T4+BTf)/(3+B)

General conduction equation:

T

Q

2T

t

c p

B Grid Biot Number

thermal diffusivit y

ha

c p

CONVECTION

Q hA(Tw T f )

Basic equation:

Stanton Number: St

h

Vc p

Reynolds Analogy: St

f

2

Grashoff Number: Gr

Prandtl-Taylor modification: St

g 2l 3 T

2

f

1

2 1 rv (Pr 1)

where: rv = velocity ratio sub-layer:free stream = 1.99 Re -0.125 for smooth tubes

Nux 0.664 Re x 2 Pr

1

On a flat plate:

1

4

For fully developed turbulent flow in tubes: Nu 0.023 Re 0.8 Pr 0.4

HEAT EXCHANGERS

Basic design equations:

Q UATlog

1

thermal resistance s hot to cold

UA

Effectiveness of a counter flow heat-exchanger:

E

1 e NTU (1C )

1 Ce NTU (1C )

Effectiveness of a parallel flow heat-exchanger:

E

1 e NTU (1C )

1 C

FINS

For long ‘thin’ fins:

cosh m( L x)

0

cosh mL

For short ‘fat’ fins:

h

cosh m( L x)

sinh m( L x)

m

0

h

cosh mL

sinh mL

m

fin

and

h

tanh( mL)

m

fin

h

h

tanh( mL)

mL

1

m

m

Area weighted fin efficiency: 1 (1 fin )

On the finned side:

Q hA 0

where

tanh( mL)

mL

and

where m

A fin

A

hp

Ax

IC ENGINES

Air Standard thermal efficiencies:

For Dual Combustion Cycle :

1

1

th 1 1

rc 1 1

For Otto Cycle :

th 1

For Diesel Cycle : th

1

rc 1

1 1

1 1

rc 1

Volume at BDC : VBDC

rc

Vs

rc 1

Mean effective pressure (MEP) =

(where Vs is the stroke volume)

Wnet

Vs

Brake or Indicated Power = PLAN

P = BMEP or IMEP

L = stroke Length

A = piston face Area

N = No. of power strokes per sec.

BSFC =

Fuel Consumptio n

Brake Power

Volumetric efficiency (for 4-stroke naturally aspirated engines)

v

vol. of free air trapped per cycle

trapped mass

swept vol. of cylinder

theoretica l mass

i.e.

v

1

2

a

m

aVs N