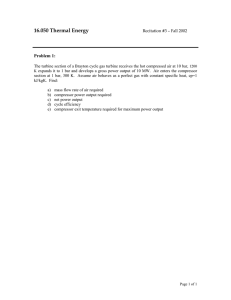

QUIZ 1 At the pressure side of the compressor 2.5 bar absolute pressure and 187°C temperature was measured, the temperature of the inflow air is 27°C, and the pressure at the suction side is 1020 hPa (1 hPa = 100Pa). Find the polytropic exponent of the compression and the polytropic efficiency of the process, if k = 1.4! (Solution: n = 1:911, npol = 0.6). Solution: 𝑛−1 𝑛 𝑇2 𝑃2 =( ) 𝑇1 𝑃1 4. Ideal gas (gas constant R = 288 J/kgK, specific heat at constant pressure is cp = 1005 J/kgK) with 27°C and 1 bar pressure is compressed to 3 bar with compressor. The exponent describing the real state of change is n = 1.5. Find the absolute temperature and density of the air at the outlet. Find the isentropic outlet temperature, the isentropic efficiency and the isentropic useful specific work if the mass ow is 3 kg/s. (Solution: Treal = 432.7K, 𝜌 = 2.407 kg/m3, Tisentropic = 410.6K, 𝜂 isentropic = 83.3%, Yisentropic = 111.48 kJ/kg) Solution: 𝑛−1 𝑛 460𝐾 2.5 𝑏𝑎𝑟 =( ) 300𝐾 1.02 𝑏𝑎𝑟 𝒏 = 𝟏. 𝟗𝟏𝟏 𝑛 𝑘−1 ( ) 𝑛−1 𝑘 1.911 1.4 − 1 𝜂𝑝𝑜𝑙𝑦 = ( ) 1.911 − 1 1.4 𝜼𝒑𝒐𝒍𝒚 = 𝟎. 𝟔 𝒐𝒓 𝟔𝟎% 𝜂𝑝𝑜𝑙𝑦 = 2. A 1 m3 rigid tank initially contains air whose density is 1.18kg/m3. The tank is connected to a high-pressure supply line through a valve. The valve is opened, and air is allowed to enter the tank until the density in the tank rises to 7.20 kg/m3. Determine the mass of air that has entered the tank. 3. The turbomachines conveying air are classified usually as fans (p2/p1 < 1.3), blowers (1.3 < p2/p1 < 3) and compressors (3 < p2/p1). Assuming p1 = 1 bar inlet pressure, t1 = 20°C inlet temperature and isentropic process (k = 1.4), find the relative density change (𝜌2𝜌1)/𝜌1 at the fan-blower border and the t2 outlet temperature at the blower - compressor border. (Solution: (𝜌2 - 𝜌1)/𝜌1= 20.6%, t2 = 128.1° C) 5. 6. Water flows through a horizontal pipe at a rate of 1 gal/s. The pipe consists of two sections of diameters 4 in and 2 in with a smooth reducing section. The pressure difference between the two pipe sections is measured by a mercury manometer. Neglecting frictional effects, determine the differential height of mercury between the two pipe sections. (Solution: 0.52 in)