Reportage Lebert

advertisement

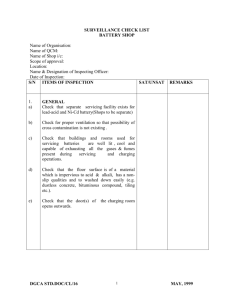

Section: Battery charging systems application reports Win-win all round High-quality battery charging technology brings users and battery dealers significant benefits in rental business Wels, Austria – Fronius battery charging systems that use Active Inverter Technology to charge traction batteries have economical and ecological benefits for the rental business. Battery dealer Keckeisen Akkumulatoren and its customer, the medium-sized logistics service provider Lebert, have opted for battery charging systems from the Austrian manufacturer. Based in Kempten, Allgäu, Franz Lebert & Co. sees itself as a proactive and complete service provider for the logistics sector. In addition to its head office in Kempten, the company has sites in Erbach and Baienfurt (close to Ulm and Ravensburg respectively) and Kreuzlingen in Switzerland. Franz Lebert set up the company in 1954 in Kempten. Today, the Lebert Group has around 400 employees, of whom 175 work in Kempten itself. In 2010, Lebert achieved a turnover of around 115 million euro’s. As partners and franchisees, the four companies in the group are part of the CargoLine network, a transport and logistics cooperative for the standardised and system-supported transport of packaged goods in Germany and Europe. Page 2 of the application report Win-win all round – high-quality battery charging technology brings users and battery dealers significant benefits in rental business Customised service André Biwer, the managing director of the Lebert Group, outlines the group's range of services: "The requirements our customers place on a logistics partner go well beyond standard haulage services. Analysing our customers' requirements and developing customised solutions are our main focus and the means by which we measure our success. Our aim is to identify the specific requirements of a customer and to provide specific, innovative solutions." The contract logistics department is located in the head office in Kempten. A high-rise warehouse covering 39,000 m2 handles the picking and ready-to-ship packaging of a variety of goods, particularly foodstuffs and food-based products. The logistics department operates between 7am and 6pm on a single-shift basis. The storage and distribution of finished products, the provision of production resources to production on just-in-time or just-in-sequence principles are among Lebert's core skills. The haulage department, which covers around 7,500 m 2, works much longer hours: three shifts a day, six days a week to be precise. This department deals with packaged goods, express products, partial and full shipments and supply chain management. Up to 2,500 haulage orders are processed every day, with an average dwell time of a product in the transit warehouse of just 20 minutes. 180 HGVs leave the company premises in Kempten every night to deliver goods to all points of the compass. Numerous Jungheinrich and Still forklift trucks are used in the haulage department so that goods can be turned round quickly and reli- Page 3 of the application report Win-win all round – high-quality battery charging technology brings users and battery dealers significant benefits in rental business ably. Also involved are electrically powered counterbalance trucks and pedestrian pallet trucks with and without platforms for loads up to 2 tonnes. Different drivers operate the forklift trucks during each of the three shifts. Due to the extreme working conditions, the trucks usually have to be replaced after four years. The department currently employs 20 trucks around the clock. Replacement batteries are used to save time and avoid interim charging. A rental concept with full service has been in use for years in the case of the forklift trucks. The benefit is fixed monthly rental instalments, which helps the company keep a close eye on its costs. In the past, both manufacturers supplied new trucks complete with the appropriate traction battery and battery charger. However, Lebert was never really happy with the servicing of its batteries and chargers. If any problems occurred, it often took too long to rectify the error or Lebert was not completely satisfied with the work done. As the forklift trucks were delivered to Lebert with batteries from different suppliers, there was often confusion regarding responsibilities when servicing fell due. This led to long downtimes for trucks and chargers, which had a profound effect on processes and disrupted schedules. Lebert came to call ever more frequently on the services of nearby battery dealer Keckeisen in Memmingen, who impressed with their quick and reliable servicing. In 2010, Keckeisen impressed the logistics company by putting forward a sophisticated rental concept to reduce costs. In addition to equipping the forklift trucks with traction batteries from the outset, this also included replacement batteries and racks, battery charging systems and a full service package. The Memmingen-based specialist guarantees a four year service life for batteries and battery Page 4 of the application report Win-win all round – high-quality battery charging technology brings users and battery dealers significant benefits in rental business charging systems. It is expected to take between two and three years before the new concept is adopted across the company as a whole. For commercial reasons, the system changeover will always take place when a new forklift truck is purchased. Twenty of the 40 vehicles at the Kempten site are now covered by the new concept. For professional use Using high-quality battery charging technology is an important part of the Keckeisen concept. The company has therefore chosen Fronius battery charging systems. "Lebert uses the Selectiva Plus range of Fronius battery charging systems," commented Gregor Holzheu, sales manager for industrial batteries at Keckeisen. He went on, "With the Selectiva product range, the Austrian company provides Intralogistics providers with battery charging systems that employ state-of-the-art technology. The systems detect the age, state of charge and other important battery parameters fully automatically and charge them correctly and precisely. In contrast to other technologies, the Fronius charging technology means the battery only heats up a little during the charging process. Gentle charging considerably increases the service life of batteries. Only in this way are we able to guarantee a service life of four years in three-shift operation at Lebert". Eleven Selectiva Plus 2065 systems for 24V/250 Ah and 375 Ah batteries, seven Selectiva Plus 2100 systems for 465 Ah batteries and two Selectiva Plus 4120 systems for 48V/625 Ah and 750 Ah batteries are used to charge the batteries of the 20 forklift trucks in the transit warehouse at Lebert in Kempten. Selectiva Plus 4120 systems are used to Page 5 of the application report Win-win all round – high-quality battery charging technology brings users and battery dealers significant benefits in rental business charge the batteries for the Jungheinrich EFG 220 and Still RX 20-18 counterbalance trucks. Replacement batteries are used in 15 forklift trucks with 24 V batteries to give charging times of between 7.5 and 8 hours. The overall concept is designed in such a way that there is no partial or interim charging during the shifts. Intelligent charging systems Fronius Active Inverter Technology achieves optimum charging power levels due to the constant charging current and voltage. A normal 230V connection can be used with the Selectiva Plus 2100 to charge vehicles with 24V/465 Ah batteries and guarantee a charging time of between 7.5 and 8 hours. With this combination, most other charger brands would require the installation of 400V three-phase AC equipment. Lebert was able to avoid expensive connection costs for the battery charging systems. Lebert managing director, André Biwer, is very happy with the Fronius battery charging systems: "Considerably less power is required to charge the batteries compared with conventional 50 Hz transformer technology. As less power is required, we are also reducing CO2 emissions. This is becoming a much more important issue for the haulage sector, since customers are increasingly looking at sustainability throughout the logistics chain. April 2011 Number of characters (main text): approx. 8,066 (without boilerplate) Page 6 of the application report Win-win all round – high-quality battery charging technology brings users and battery dealers significant benefits in rental business Fronius battery charging systems at Lebert head office in Kempten Quantity Type Mains voltage/current 11 Selectiva Plus 2065 24V / 65 A 7 Selectiva Plus 2100 24V / 100 A 2 Selectiva Plus 4120 48V / 120 A Battery capacity 24V 250 Ah and 24V 375 Ah 24V 465 Ah 48V 625 Ah and Internet sites of the companies mentioned: Franz Lebert & Co.: www.lebert.com Keckeisen Akkumulatoren: www.akkudirekt.de Fronius battery charging systems: www.fronius.com/intralogistik Your contact for enquiries: Fronius International GmbH Battery Charging Systems division Boris Ringwald Division Marketing Froniusplatz 1 A-4600 Wels, Austria Tel.: +43 (0)7242 241 6436 Fax: +43 (0)7242 241 952 560 ringwald.boris@fronius.com www.fronius.com 48V 750 Ah Page 7 of the application report Win-win all round – high-quality battery charging technology brings users and battery dealers significant benefits in rental business Selection of pictures: Photo credit: Fronius International GmbH Fig. 1 Head office of logistics service provider Lebert & Co. in Kempten, Allgäu (photo: Lebert) PI_Fronius_Lebert_01 Fig. 2 Up to 2,500 haulage orders are processed and loaded onto 180 HGVs every day in the transit warehouse. PI_Fronius_Lebert_02 Fig. 3 Managing director of the Lebert Group, André Biwer (left) with Gregor Holzheu, sales manager for industrial batteries at Keckeisen Akkumulatoren. PI_Fronius_Lebert_03 Fig. 4 Fronius Selectiva battery charging systems reduce energy costs for Lebert and increase battery service life for Keckeisen. PI_Fronius_Lebert_04 Fig. 5 The Keckeisen concept uses replacement batteries in three-shift operation. PI_Fronius_Lebert_05 The photos shown here are preview images that have been reduced in size. Page 8 of the application report Win-win all round – high-quality battery charging technology brings users and battery dealers significant benefits in rental business Fronius - the company Fronius International is an Austrian company with headquarters in Pettenbach and other sites in Wels, Thalheim and Sattledt. With over 3,250 employees worldwide, the company is active in the fields of battery charging systems, welding technology and solar electronics. Around 90% of its products are exported through 17 international Fronius subsidiaries and sales partners/representatives in over 60 countries. In financial year 2009, the company generated a total turnover of 329 million euros. With its outstanding products and services and 691 active patents, Fronius is world technology leader. 358 employees work in research and development. The Battery Charging Systems division is the oldest division in the company. It was founded in 1946. This division develops and produces charging systems for traction batteries based on Active Inverter Technology. The particular characteristics of this technology include intelligent charging technology, high energy efficiency, constant power throughout the charging process, a compact form factor and high safety standards.