Foam

advertisement

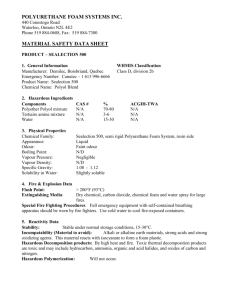

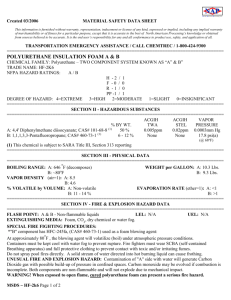

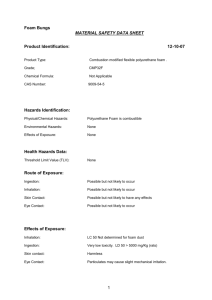

Expandable Polyurethane Foam MTI Summer 1999 Page 1 Expandable Foam Products NHP Expandable Liquid Foam NHP Co., Inc. Lowell, MA 01851 Rigid Polyurethane Foam. Contains: methylene diphenyl and polymeric methylene diisocyantes, polyol, and an amine catalyst. Store between 40 F (4 C) and 80 F (27 C) 1. 2. 3. 4. Avoid contact with eyes and skin. Always use adequate ventilation Clean and dry surfaces THOROUGHLY Unscrew caps SLOWLY to release any pressure in containers Pour equal amounts of PART A and PART B into a disposable container or preferable into an NHP graduated mixing cup for more accurate measurement. 5. MIX THOROUGHLY for 30 seconds or until foam begins to form on liquid surface. For boat flotation, pour a very thin bead along sides of hull and on underside of deck by turning boat over. Apply quickly since working time is approximately 30 seconds. Expands completely in 5 minutes. Can be handled in 20 minutes. Fully cures in 5 minutes. It is advisable to experiment with his product before doing the job intended. A 1/8 " layer will expand to approximately a 3" layer. 1 liquid ounce will expand to the equivalent of 25 liquid ounces. Sets at room temperature Working time Expands completely Can be handled Fully cured 15 minutes 30 seconds 4 minutes 20 minutes 30 minutes Fiberlay Fiberfoam Fiberlay Inc. 2425 NW Market St Seattle, WA 98107 Technical Service: 206.782.0660 Product Orders: 800.942.0660 Fax: 206.782.0662 http://www.fiberlay.com 60 pounds/ft3 buoyancy Part A: Reactive isocyanate TOXIC Part B: Volatile fluorocarbon liquid, boils at 74F, volatizes at room temperature D:\106736519.doc 02/15/16 Expandable Polyurethane Foam MTI Summer 1999 Page 2 Mix equal parts for about 30 seconds. When becomes cloudy, pour immediately. Produces a 2 pound density closed cell foam. Fiberfoam will expand approximately 22 times its liquid volume at room temperature. Note: the product can states "1 quart of resin will equal 1 gallon of expanded foam." This is about 30 times expansion. To fill a 500 ml (1.05 pt) water PET bottle, I used about 1/4 oz of Part A and 1/4 oz of Part B. Great Stuff - Minimal Expanding Foam Sealant Flexible Products Company 2050 North Broadway Joliet, Illinois 60435 800-800-3626 http://www.flexibleproducts.com All purpose Polyurethane Foam Sealant. Highest insulation value (1 inch = R5). 4,4-Diphenylmethane-diisocyanate Polymeric Polyther Polyol Blend Chlorodifluoromethane Trisphosphate 30-60% 30-60% 15-40% 15-40% 3-7% Other Information Polyurethane Foam for Roofing Applications http://www.foamroofing.com/aboutSPF.html Sprayed Polyurethane Foam is a combination of isocyanate and polyol. These two components are fed through a proportioner which heats then pumps the two separate components to the spray gun, where they are mixed and sprayed onto the substrate. Because it is sprayed onto the roof as a liquid, it forms a single continuous structure that is seamless and very stable. SPF requires a clean surface for proper application. It must be dry, free of contaminants like oil, and properly fastened to the substrate in accordance with the proper building codes. A protective elastomeric top coat is required which is typically sprayed on as well, but it is also possible to be applied with hand or power rollers. D:\106736519.doc 02/15/16 Expandable Polyurethane Foam MTI Summer 1999 Page 3 Polyurethane Chemistry http://polyurethanes.huntsman.com/ All polyurethanes are based on the reaction which takes place when two liquid chemicals - a diisocyanate and a polyol - are mixed together in the presence of suitable catalysts and additives. The reaction that occurs when the two are combined is exothermic, meaning that heat is generated. The polymer reaction is chemically efficient and, with the addition of a catalyst, allows extremely fast and large volume production runs. No unwanted by-products are given off and, because the raw materials react completely, no after-cure treatment is necessary. By itself, the polymerisation reaction produces a solid polyurethane. Polyurethane foams are made by forming gas bubbles in the polymerising mixture, which is achieved by using a 'blowing' agent. Flexible foams are usually made using the carbon dioxide formed in the reaction of water and isocyanate (water blowing). Blowing agents for rigid foams include HCFCs (hydrochlorofluorocarbons), HFCs (hydrofluorocarbons) and pentanes. Relatively few basic di-isocyanates and a range of polyols of different molecular weights and functionalities are used to produce the whole spectrum of polyurethane materials. Polyols The polyols that are used to make polyurethanes have been developed to have the required reactivity with commercially available di-isocyanates and to produce polyurethanes with specific properties. Most polyols and polyisocyanates used in the manufacture of polyurethanes are liquid at ambient temperatures (ca. 18°C) and are easily handled. The choice of polyol, especially the size and flexibility of its molecular structure and its functionality (the number of isocyanate reactive hydroxyl groups per molecule of polyol) controls, to a large extent, the degree of cross-linking achieved in the polymer that is formed in the reaction with the di-isocyanate. That degree of cross-linking has a dominant effect on the stiffness of the polymer: to obtain a rigid foam there must be a stiff polymer network, and, hence a high degree of cross-linking; for flexible foam a proportionately lesser degree of cross-linking is needed. Polyisocyanates An important method of varying the properties of the final polyurethane is by varying the type of di-isocyanate used. Di-isocyanates may be modified in many ways to give products with differing physical and chemical properties. Polyurethanes are based on two polyisocyanates: diphenylmethane diisocyanate (MDI), in which Huntsman Polyurethanesspecialises, and toluene diisocyanate (TDI). Both are derived from readily available petrochemical intermediates and are manufactured by well understood and closely defined chemical processes. D:\106736519.doc 02/15/16 Expandable Polyurethane Foam MTI Summer 1999 Page 4 The production chemistry of MDI is considerably more complex than that of TDI. However, this complexity gives a significant degree of freedom to the chemical manufacturer, enabling them to modify and optimise grades of MDI to meet specific user needs. To make polyurethanes as cost-effective as possible, producers of di-isocyanates have developed processes for tailoring the MDI composition to the requirements of the end product. The polyisocyanate mixtures are formulated to offer a range of differing functionalities. Additives Apart from polyisocyanates and polyols - the basic materials for polyurethane production - a wide variety of auxiliary chemicals may be added in order to control and modify both the polyurethane reaction itself and the properties of the final polymer. These additives include catalysts, cross-linking agents, chain-extending agents, blowing agents, surfactants, colouring materials, fillers and flame retardants. All practical polyurethane systems include at least some of these auxiliary chemicals. Glosary Blowing agent - A substance incorporated in the polymerising reaction mixture between a diisocyanate and a polyol to form gas bubbles, thereby producing foam. Branching - Lateral extension points in a polymer chain. Catalyst - A substance which accelerates the reactions of chemicals without being consumed itself. Chain extenders - Substances which lengthen the main chain of a polymer molecule causing end-to-end attachments. Cross-linking - Formation of bridges between different polymer chains. Cure - Refers to the completeness of the chemical reaction processes. Di-isocyanate - A reactive chemical grouping of a nitrogen atom bonded to a carbon atom bonded to an oxygen atom; -N = C = 0; a chemical compound, usually organic, containing one or more isocyanate groups. Elastomer - A synthetic rubber-like material capable of rapid, reversible extension. Filler - An inert material added to a polyurethane reaction mixture. Fillers are usually solid, particulate materials such as glass, silica or barytes. Flame retardant - An added substance which inhibits the initiation and/or spread of flame. D:\106736519.doc 02/15/16 Expandable Polyurethane Foam MTI Summer 1999 Page 5 Functionality - The number of reactive groups in a chemical molecule. Hydroxyl - An alcoholic group (-O-H). The reactive group in polyols. Mould - Enclosure, usually metal, in which a polyurethane mixture reacts to give a shaped article. Polyisocyanate - A polyisocyanate contains more than one isocyanate group. Polymer (Copolymer) A substance, natural or synthetic, which can be represented as at least two repeated monomer units. A copolymer contains more than one type of monomeric unit. Polyol A substance containing several hydroxyl groups. A diol, triol and tetrol contain 2, 3 and 4 hydroxyl groups respectively. Polyurethane - Polymeric substance containing many urethane linkages. Self skinning - A foam reaction mixture which forms a skinned surface on being moulded at a specified temperature and pressure. Slabstock - Rigid or flexible polyurethane foam made in the form of a continuous block, usually of approximately rectangular cross-section. Surfactants - Selected surfactants (surface-active materials), or mixtures of surfactants, help in mixing incompatible components of the reaction mixture. Urethane - The chemical group D:\106736519.doc 02/15/16