extraction of nanoparticle iron (iii), silica and calcium sulphate from

advertisement

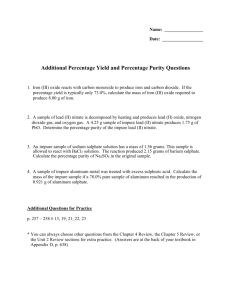

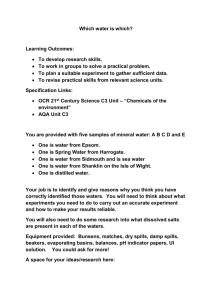

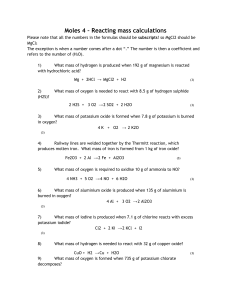

EXTRACTION OF NANOPARTICLE IRON, SILICA AND CALCIUM SULPHATE FROM ELECTRIC ARC SLAG Zaiton Abdul Majid,* Nor Aziah Buang and Muhammad Zamir Othman, Department of Chemistry, Faculty of Science Universiti Teknologi Malaysia *Email: zaiton@kimia.fs.utm.my Industrial waste material such as electric arc (EA) slag produced in the steel industry consists largely of iron oxide, calcium oxide and silica. Studies on the EA slag have mainly focused on utilization or recycling of the EA slag, namely its application in the construction industry as recycled aggregate in the road construction as well as its potential in the treatment of phosphate containing wastewater. This research reports on a novel method of extraction of iron oxide from EA slag to be used as a catalyst in the production of carbon nanotubes (CNTs). The extraction process breaks down the perovskite structure of EA slag into nanoparticle size using top down principle. Besides the iron oxide, the extraction method also produced precious side products namely, silica and calcium sulphate. The slag used in this study was obtained from Antara Steel, Pasir Gudang, Johor. The EA slag was ground and sieved before treatment with ammonium nitrate followed by sodium hydroxide and heat treatment at elevated temperature The filtrate collected in ammonium nitrate and sodium hydroxide extraction processes were further treated to produce silica and calcium sulphate. Field Emission Scanning Electron Microscope (FESEM), Energy Dispersive X-Ray Analysis (EDX), X-ray diffraction (XRD), Fourier Transform Infrared Spectrophotometer (FT-IR), and BET Surface Analyzer were used to characterize the treated slag, silica and calcium sulphate. The results obtained showed that nanoparticle iron was successfully extracted from the EA slagwith a surface area of 72.51 m2/g. The EDX analysis showed high percentage of iron in the treated slag. Amorphous silica was successfully produced with a surface area of 133 m2/g and >90% purity. The XRD diffractogram illustrates clearly the existence of amorphous silica. This was further supported with the morphology of the amorphous silca as shown by FESEM. Additionally, 99% of microsize calcium sulphate was successfully produced. FESEM analysis suggests that the calcium sulphate obtained is of high purity and have well crystalline structure of plane and rod like shaped. With this novel and simple extraction process, high yield and purity of iron oxide, silica and calcium sulphate were successfully extracted from EA slag.