Technical specs of Briquettes type Boiler

advertisement

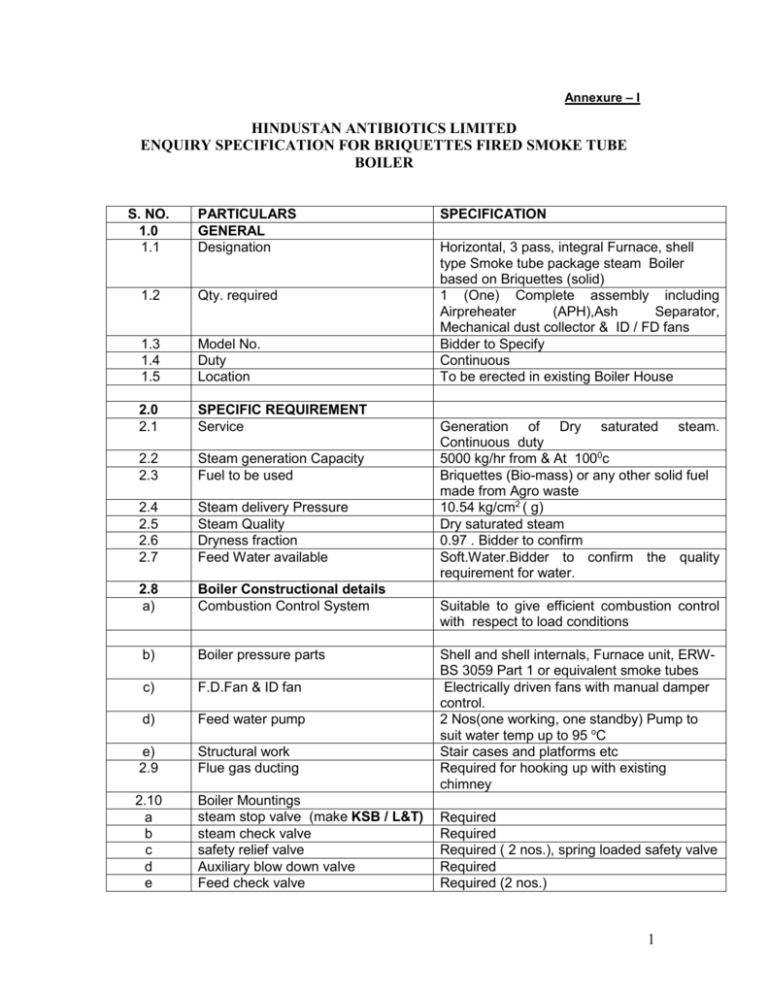

Annexure – I HINDUSTAN ANTIBIOTICS LIMITED ENQUIRY SPECIFICATION FOR BRIQUETTES FIRED SMOKE TUBE BOILER S. NO. 1.0 1.1 PARTICULARS GENERAL Designation 1.2 Qty. required 1.3 1.4 1.5 Model No. Duty Location 2.0 2.1 SPECIFIC REQUIREMENT Service 2.2 2.3 Steam generation Capacity Fuel to be used 2.4 2.5 2.6 2.7 Steam delivery Pressure Steam Quality Dryness fraction Feed Water available 2.8 a) Boiler Constructional details Combustion Control System b) Boiler pressure parts c) F.D.Fan & ID fan d) Feed water pump e) 2.9 Structural work Flue gas ducting 2.10 a b c d e Boiler Mountings steam stop valve (make KSB / L&T) steam check valve safety relief valve Auxiliary blow down valve Feed check valve SPECIFICATION Horizontal, 3 pass, integral Furnace, shell type Smoke tube package steam Boiler based on Briquettes (solid) 1 (One) Complete assembly including Airpreheater (APH),Ash Separator, Mechanical dust collector & ID / FD fans Bidder to Specify Continuous To be erected in existing Boiler House Generation of Dry saturated steam. Continuous duty 5000 kg/hr from & At 1000c Briquettes (Bio-mass) or any other solid fuel made from Agro waste 10.54 kg/cm2 ( g) Dry saturated steam 0.97 . Bidder to confirm Soft.Water.Bidder to confirm the quality requirement for water. Suitable to give efficient combustion control with respect to load conditions Shell and shell internals, Furnace unit, ERWBS 3059 Part 1 or equivalent smoke tubes Electrically driven fans with manual damper control. 2 Nos(one working, one standby) Pump to suit water temp up to 95 oC Stair cases and platforms etc Required for hooking up with existing chimney Required Required Required ( 2 nos.), spring loaded safety valve Required Required (2 nos.) 1 f g h i j k l m n o Feed water regulator/controller Valve for soot blower of APH ( 1 No.), Drain valve after gauge glasses ( 2 Nos.) and air vent ( 1 No.) Valves make KSB / L&T Blow down valve (make KSB / L&T) Water sampling valves & associated piping Flame observation ports Manhole for shell with self tightning arrangement Water level indicator/Gauge glasses with cocks Pressure gauges for steam pressure 3.1 Feed water pressure Boiler Inspector's Test pressure gauge arrangement DESIGN / CONSTRUCTION FEATURES Codes & Standards 3.2 System Requirement 3.3 a) Boiler Accessories Combustion Control System b) Boiler pressure parts i. Shell and shell internals ii. iii. Furnace unit Smoke tubes (ERW-BS 3059 Part 1 or equivalent) 3.0 Required Required Required Required Required Required Required Required Boiler mounted type (Dial size 12”) Required, mounted at pump outlet Required a) The complete equipment assembly supplied and installed shall conform to high standards of engineering design/workmanship and shall comply with all currently applicable statutory regulations, prevailing safety rules/codes (especially IBR requirements), Engineering standards and Boiler Act IBR 1950 with latest amendment Nothing in this specification shall be construed to relieve the vendor of this responsibility. b) As far as possible, individual equipment/component parts shall conform to ISI standards. All Nut & Bolts, Bearings, Seals etc. shall conform to metric standards Boiler should be horizontal shell type fully packaged 3 pass, Briquettes fired Boiler .Boiler shall be proven under rigorous condition & subject to the strict quality control procedures. Suitable to give efficient combustion control with respect to load conditions Bidder to confirm & furnish thickness & material of construction ---------------do---------------------------do------------- 2 c) F.D.Fan / I.D.Fan d) Feed water pump e) f) structural work Flue gas ducting 3.4 a i Boiler Instrumentation Temp. indicator(local mounted) for : smoke temperature Ii iii Iv v vi Feed water inlet temp Saturated steam temp Flue gas temp at boiler outlet Flue gas temp at APH inlet Flue gas temp at APH outlet b i ii iii iv v vi vii c d e f g h Audio/Visual alarms/shutdown for Low feed water flow Low and high water level Extra low water level trip High steam pressure trip Feed water pump failure ID / FD fan failure Low combustion air quantity Combustion control system Steam flow and pressure control Boiler Feed water level control system Motor overload protection Measuring instruments Steam flow meter i Other Miscellaneous 3.5 3.6 3.7 i ii 4.0 4.1 4.1.1 Interlock between ID / FD fans Combustion efficiency Grate & Ash removal system Ash separator Openable furnace door for feeding briquettes Acceptable Make of various equipments Electrical Drive Motor F.D.Fan / I.D. Fan with damper control as per design for Boiler load / draught conditions. Bidder to indicate flow rate and static pressure of the fan offered 2 Nos (one working, one standby)Pump to suit water temp up to 95 oC Stair cases and platforms etc to be included. Required for hooking up with existing chimney Required. Bidder to furnish the details make, temp range ,dial size 6”, ---------------do---------------------------do---------------------------do---------------------------do---------------------------do------------- Required. Bidder to confirm. ---------------do---------------------------do---------------------------do---------------------------do---------------------------do---------------------------do------------Manual controls for load, steam pressure, Required Required Required Required. Orifice type with differential pressure transmitter All thermocouples/pyrometers, thermostats etc shall be provided wherever necessary. Required. Bidder to confirm Bidder to confirm with & without APH. Bidder to confirm the hole size of grate & ash removal facility. Bidder to confirm TEFC drive from Siemens / Compton Greeves/ NGEF ,IP 55,Class F 3 4.1.2 4.1.3 4.1.4 4.1.5 4.1.6 4.1.7 4.1.8 4.1.9 4.1.10 4.1.11 4.1.12 4.2 4.3 4.4 4.4.1 4.4.2 4.5 Motor Starter( contactors & overloads) Switches/switch fuses/fuses PVGA cables Cable glands Cable lugs/sockets Wattmeter/KWH meter ( multi function electronic meter ) Current transformers Push Buttons Timer Limit Switches Contactors Earthing Indication for Equipment "ON/OFF" Instruments Pressure gauge Temperature gauge Blower i 5.0 Scope of Work/Supply 5.1 Bidder's scope of work/supply Boiler With Combustion Control iii FD fan / ID fan with ducting iv Feed water pump with necessary piping vi Control panel Assembly vii Accessories Siemens / L&T Siemens / L&T Polycab / Finolex / KEI Electro mech / Siemens / Braco Dowel / Hillpress / comet GEC /Universal / Rishabh Precise /Gilberts & Mackwell Siemens / L&T / Teknik Cutler & Hammer Siemens / Kaycee /Telemechanic Siemens/ L&T G.I.Flat /Wire double galvanised Required, Bidder to confirm Bestobell /H.Guru / waree / Gluck Bestobell /H.Guru /General Instruments / Waree Bidder to indicate make, flow rate and static head One no. Briquettes fired 5.0 TPH (from & at 1000c) Boiler with suitable furnace for Briquettes firing & ash removal system with instrumentation control system as specified in Enquiry specification Backward curved design FD fan with motor & ducting at suction & discharge Two no. (one running & one as stand by) centrifugal multistage vertical feed water pumps (to suit 950c water temp)with motor along with the necessary piping One no. power cum control panel physically isolated with partition plate standing type, confirming to IP 42 with MCB/MCCB. Panel 14/16 SWG CRCA sheet & painted with synthetic enamel paint The power section is provided with a main incomer isolating switch with MCCB. Ammeter and voltmeter shall be provided at the incomer. Ammeter & voltmeter with phase selector switch shall be provided for each motor. Control Panel shall also comprise of Flame failure Indicator, flue gas temp at outlet of Boiler, flue gas temp at inlet of APH, flue gas temp at outlet of APH, KWH meter, Alarm & indications required. Bidder to confirm, Pressure Control switches a) Air ducting : 4 viii Structure ix x Insulation & Cladding Piping Work ( IBR approved) xi Installation & commissioning 5.2 i HAL's Scope of Work/Supply Civil work i. Cold ducting from FD fan to APH. ii. Hot ducting : a. APH to Boiler furnace b. Boiler outlet to dust collector c. Dust collector to ID fan d. ID fan to chimney b) Piping: Set of feed water piping to connect feed water pumps to the boiler ( one no.) c) Stop valves on feed water line (Two no.) NRV on feed water line (Two no. ) pressure gauges at the outlet of pump ( Two no. ) Isolation valves for the pressure gauges (Two no.) d) Set of valve mountings & fittings for the Boiler: Main steam stop valve ( one no.) e) Spring loaded single port safety valves (Two no.) Air vent valve ( one no,) Blow down valve (one no.) f) Plain tubular gauge glass along with inbuilt isolation and drain valves (Two no.) float operated magnetic water level controller ( One no) g) Isolation & drain valves ( two nos.) for main steam pressure gauge, inspector's pr. gauge Drain valve for the float operated level controller (one no.) h) Explosion door for protection against high flue gas pressure Set of ladder & catwalk to operate the valves & fitting mounted on the Boiler For above Boiler & related piping a) Piping from existing feed water tank to Boiler b) Piping from main steam stop valve to existing steam header c) Steam flow meter : Impulse pipe to be laid up to instrument control panel d) Blow down piping from main blow down valve to blow down pit e) Piping for gauge glass drain & mobrey drain up to existing drainage Supplier to depute his technical person for installation and commissioning of the Smoke tube Boiler. a) Construction of foundation for boiler. b) Construction of blow down pit. c)Construction of drainage from main blow down valve to blow down pit 5 ii Utilities iii Services available iv vi vii Compressed Air Water Inspection 6.0 Data to be furnished by the Bidder alongwith the Bid General Name of the supplier & his postal address Place of manufacturer & postal address Service and testing facilities available with manufacturer Guaranteed delivery period/period of mechanical completion and commissioning Guaranteed Boiler Performance Maximum continuous steamevaporation from & at 1000C Kg/hr(MCR) Net continuous output of the boiler Kg/hr at 10.54 kg. / cm2 Designed steam pressure Kg/cm2 Designed steam temperature deg C Steam outlet pressure(g) Maximum variation in steam pressure for the complete range of operation Time required to raise the boiler to its normal continuous output at full pressure Boiler performance (Predicted) And Design features Maximum evaporation(Kg/hr) at designed pressure and Feed water temperature of:100 deg C: 30 deg.C 6.1 a b c d 6.2 a b c d e 6.3 6.4 6.5 6.6 a)Electricity, compressed air & soft water will be made available for erection of boiler b) Feed water supply up to feed water tank is available Power supply a) 415 V+/-10%, 3 phase, 4 wire,50 HZ,A.C. supply at single point, near plant room. b) 230 V +/- 10%,Single phase,2 wire, 50 HZ, A.C. Supply, at one point near plant room. At 4.5 Kg/cm2(g) Soft Water / D.M. Water. Inspection of Smoke tube Boiler will be done at the supplier’s work site by HAL technical team before dispatch. Supplier to inform HAL in advance for inspection before dispatch. 6 6.7 6.8 6.9 6.10 6.11 6.12 6.13 6.14 6.15 6.16 6.17 6.18 6.19 6.20 6.21 Boiler HP Total heating surface Boiler Thermal Efficiency at various load i.e. 100% 75% 50% Safety valves setting pressure 1st post & 2nd post Recommended quality of Feed water Briquette consumption at various loads 100% 75% 50% Minimum stable output conditions Quantity of air leaving FD Fan / ID fan Quantity of gas leaving Boiler Excess air at Boiler outlet Overall dimensions as installed(LxBxH) Clear space required for removal & cleaning at front end at back end Performance curves to be furnished for the boiler Load vs Efficiency Load vs fuel consumption Load vs O2 content in flue gas Briquettes burning system Furnace type Ash removal system Boiler Feed water pump Make Type Size & catalogue No. Number of pumps Feed water temperature at pump suction NPSH requirement HP/KW RPM/Flow Pump designed temperature List of accessories Delivery pressure Motor details 7 6.22 6.23 6.24 6.25 Make Type Type of enclosure Insulation class Voltage and design HP RPM/No. of poles Type of starters, overload & size of cable used Forced Draft ( F.D.) fan Type Manufacturer Size & catalogue No. Fans speed HP No. of fans provided Volume of air delivered at designed temperature Static pressure developed at designed temp. Air temperature Designed Operating Motor Details Make Type Type of enclosure Insulation class Voltage and design HP RPM / No. of poles Type of starters, overload & size of cable used Characteristic curves Safety relief valves Make Number Size Type Capacity Set pressure Gauge glass fittings Make Number Size Type Special features Gate and Globe valves Make 8 6.26 a b c d e 6.27 6.28 i ii ii Material of construction of body and internal parts Details of Boiler Shell #Length (m) #Internal Diameter (m) #Material of Construction Tube #Length (m) #Internal Diameter (m) #Material of Construction No. of Tubes Water content when full ( m3) Water content at working level ( m3) Steam space Design code Wet back / Dry back No. of Passes Insulation #Class #Type #Thickness (mm) Weight of the main unit #Operating Weight #Flooded Weight Accessories Air Preheater (APH) Designed draft loss across APH Type Material specification constructional details Insulation thickness heating surface area Chimney Existing Chimney to be used Control panel Boiler control/Instrument-control electric panel Type ( single or double door) Size Sheet thickness List of instruments mounted on the panel List of Protective fuses, voltmeters, ammeters, Kwh meters, selector switches for auto / manual operations indicating lamps etc mounted on panel 9 6.29 i ii iii iv a b c d v a b c d e f g vi List of controls mounted on panel Control Panel load (KW) Boiler control and Instrument Details Combustion control system Steam flow and pressure control system Feed water and Drum level control system Measuring Instruments (Type & Make) O2 analyzer, indicator & recorder Feed water flow indicator & integrator Steam flow indicator & integrator(Orifice type) Recorder for steam flow Audio /Visual Alarms /Trip system Low feed water flow Low and high water level Extra low water level trip High steam pressure trip Feed water pump failure ID / FD fan failure Low combustion air quantity Miscellaneous 7.0 i Optional accessories Bag filter ash separator ii 8.0 O2 analyzer indicator & recorder Following documentation shall accompany with the Technical bid. Scope of supply including accessories quoted Relevant Catalogues/Technical literature/IBR Document/Approved Drawing and specification for smoke tube Boiler as well as for boughtout items Equipment layout drawings (including main equipment alongwith all accessories) and indicating overall General dimensions and weight. Details of utilities viz * Specifications * Consumptions 8.1 8.2 8.3 8.4 All thermo couples/guards, pyrometers, thermostats, etc shall be provided wherever necessary. The list and location shall be furnished by the bidder. Required to meet MPCB norms for particulate matter through chimney. Bidder to quote separately Required. Bidder to quote separately To be confirmed clearly. Required Required To be indicated in detail. 10 8.5 8.6 8.7 9.0 9.1 9.2 9.3 9.4 9.5 9.6 9.7 9.8 9.9 9.10 9.11 9.12 9.13 10.0 * Size/standards of all terminal connections Electrical & Instrumentation Circuit diagram List of Users of the quoted model supplied by Bidder in last 2 years, yearwise. The following documents shall also accompany the "Price Bid" a) Price Break-up of main equipment & accessories quoted b) Separate price-list for essential Spares for 2 years trouble-free operation Data/Documents to be furnished by Bidder after order placement Detailed Drawings of the Boiler including accessories Piping drawings for approval Detailed Drawings of the instrumentation & control panels Electrical wiring diagram showing interlocks controls, wiring sizes & rating of each electrical equipments for approval P & I diagram for approval Installation, Operation & Maintenance manual including drawings Materials test certificates for smoke tube Boiler including motor & other bought-out items Separate list of essential Spares for 2 years trouble-free operation Manufacturer's outline drawings / catalogue for Boiler feed pump, Blowers, valves etc Test reports and plant handing over reports after commissioning Copy of IBR approved drawings/documents Reproducible of all Approved Drawings Approved Drawings copies Confirmation of specification Required To be indicated with communication details. Required Required 4 sets 3 sets 4 sets 3 sets 3 sets 4 Sets required. 4 Sets required Required 4 sets 6 sets 3 sets 1 sets 3 sets Bidder to confirm the specification of the complete system details as stipulated, here in this specification parameters in conformity with desired operating requirements and design /construction features. Any deviations from the stipulated specification shall be 11 Bid Documentation 11.0 12.0 Performance guarantee 13.0 Other Requirements a Inspection b Installation & commissioning clearly brought out. The makes/brands and names of all bought out proprietary equipments are subject to approval by HAL Bidder to quote "Technical Bid" & "Price Bid" separately with clear marking on the envelope. There should not be any indication of "Price quoted" in Technical bid. a) The manufacturer shall guarantee the rated output of the Boiler during normal operation b) Guarantee trials shall be carried out by manufacturer during installation of c) The manufacturer shall replace / repair free of cost replacement of the defective parts due to wrong design / inferior workmanship within a period of one year from the date of commissioning of the machine or 18 months from the date of supply whichever is earlier. Inspection of Boiler – Briquettes based will be done at the supplier’s work site before . Supplier to inform HAL in advance for inspection before dispatch. Supplier to depute his technical person for supervision during installation and commissioning of the Boiler – Briquettes based at HAL's site free of cost Bids shall be submitted in two Parts viz. I) Technical Bid 2) Commercial Bid in separately sealed covers. Technical bid shall have no reference to price & should be submitted in duplicate Bidders shall forward technical bid and commercial bid in separately sealed envelops clearly superscribing on envelop as “Package Boiler (Briquettes) - Technical Bid” & “Package Boiler (Briquettes) - Commercial Bid”. 12