Cannizzaro Reaction Lab Experiment: Benzaldehyde to Alcohol

advertisement

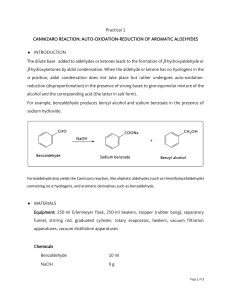

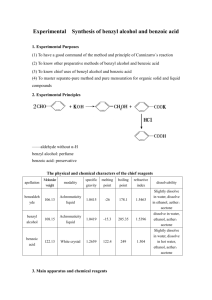

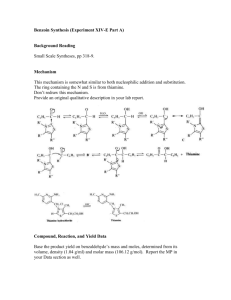

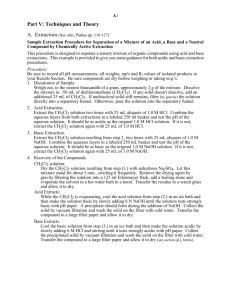

EXP-7 CHEM 233L THE CANNIZZARO REACTION Introduction: The Cannizzaro reaction is that of aldehydes that do not contain alpha hydrogens to give carboxylic acids and alcohols (alpha hydrogens cause an Aldol reaction to take place). This occurs in the presence of a strong base. Benzaldehyde, which does not contain alpha hydrogens, was used for this reaction. The refulx technique will be used in order to allow for a complete reaction between all the components. On completion of the reaction, the extraction technique will enable the separation of benzoic acid and benzyl alcohol. This will be achieved by the ionization of Benzoic acid which will separate from the organic benzyl alcohol. Reacidification will reform the Benzoic acid. The analysis of the benzyl alcohol will be done by completing a series of qualitative tests: the Jone’s test, Tollen’s test, and 2,4-DNP test. The Jones’ test will check for the presence of an aldehyde or a 1o and 2o alcohol. This result can be confirmed by the Tollen’s test which checks for the presence of an aldehyde. 2,4-DNP test will verify the presence of an aldehyde or a ketone. These tests will permit one to determine if benzyl alcohol was indeed produced. Main reaction: O O H + O OH KOH H OH + CH3OH H H Reflux Benzoic acid The Cannizzaro reaction was discovered in 1853 by the Italian chemist Stanislao Cannizaro (1826-1910). Benzyl alcohol Table of Physical Data: Compound Name Molecular Melting Boiling Density Solubility Precautions Weight point point (g/ml) o o (grams) ( C) ( C) O H 106.124 -26 179 1.045 32.042 -98 64.6 0.791 56.097 -- -- 2.044 84.933 -96.7 39.8 1.326 18.0152 0 100 0.995 122.123 122.2 249 1.08 108.139 -15.3 205 1.045 Benzaldehyde OH H H H Methanol solvent 10 M KOH H H Cl Cl CH2Cl2 Extraction solvent H2 O Extraction solvent O OH Benzoic acid OH H H Benzyl alcohol Safety Notes: Benzaldehyde is toxic and flammable. Avoid contact with skin, eyes, and clothing and dispense it under the hood condition. Potassium hydroxide and hydrochloric acid are corrosive Procedures: Exp 7A: 1. Place about 3.0 ml of benzaldehyde, 15 ml of methanol and 2 ml of aqueous 10 M KOH in a 100 ml round bottom flask; add a couple of boiling chips finally. 2. Attach a reflux condenser and heat the reaction mixture to the boiling point of methanol for 1 hour. 3. Allow the mixture to cool down and place in an ice bath. 4. Transfer the mixture carefully to a separatory funnel with the help of 15ml of CH2Cl2 and addition of 10 ml of water. 5. Shake the separatory funnel and separate the layers. The benzoic acid (as potassium benzoate) will stay in the water phase, while the benzyl alcohol and benzaldehyde will remain in the lower organic phase. 6. Extract the organic phase with 10 ml of water and combine the water with the first aqueous phase. 7. Back-extract the combined aqueous phase 2 times with 5 ml of CH2Cl2. 8. Save the organic layer as well as the aqueous layer for the next lab. Exp 7B: Organic Phase Work-up: 1. Dry the combined CH2Cl2 phase over by anhydrous MgSO4. Add enough drying agent so, the solution appears clear as opposed as cloudy. 2. Remove MgSO4 by filtration. Rinse the MgSO4 with 5 ml of CH2Cl2 drop wise using a pipette. 3. In the hood, evaporate the CH2Cl2 by using a hot plate and a water bath to gauge the temperature. Keep the hot plate around 30-40 0C. 4. Dissolve the oily residue in 2 ml of CH2Cl2 and transfer the solution to a tarred vial. 5. Evaporate the CH2Cl2 completely again, over a hot plate kept at low heat (30-40 oC). 6. Use the flask with water and a thermometer to gauge the temperature. 7. Determine the yield of the oily residue. Perform some qualitative tests and then take the IR of your product and submit the rest. Reference: www.chemfinder.com