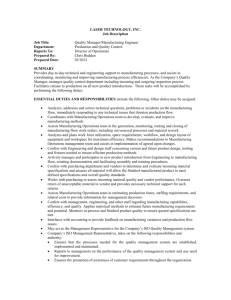

Ruderfer & Associates, Inc. Irwin A. Ruderfer, CPC, President 25

advertisement

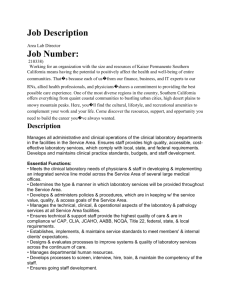

Ruderfer & Associates, Inc. Irwin A. Ruderfer, CPC, President 25 Pompton Ave., Verona, N.J. 07044 Tel: (973)239-2000 Fax: (973)239-9080 e-mail: irwin@ruderfer.com Position Director of Quality Assurance and Regulatory Affairs Company: Atlanta, Ga Class 1 Medical Device manufacturer located outside of Compensation $150K- 175K + 10% Bonus + Relocation Offered Reports to CEO Our client is an FDA registered, ISO 13485.2003 certified engineering and manufacturing outsource Service Company providing design, development and manufacturing services to the medical device marketplace. They specialize in developing and manufacturing hand-held devices (including reusable and disposable components) that are precise and highly intuitive in the hands of patients and end-users. POSITION SUMMARY This position is responsible for establishing strategic plans, policies, and procedures at all levels to ensure the QA program will meet or exceed internal and external customers needs and expectations. General responsibilities include implementation, coordination and direction of corporate Quality Systems directly and through all activities of personnel and equipment engaged in design, testing, regulatory compliance, auditing, CAPA and customer complaints. Corporate quality system reflects activities in all aspects and locations of Facet. Provides functional guidance to direct reports and implements the vision of World-Class initiatives, continuous improvement and full compliance to all regulating standards. PRINCIPAL RESPONSIBILITIES include the following. Other duties may be assigned. Establishes and implements Quality and regulatory strategic plans and policies. Develops and implements methods and procedures for inspection, testing and evaluation of products. Develops and manages departmental operating and capital budgets Manages all QA Engineers, Supervisors, Inspectors, Regulatory Specialists and Technicians. Develops staff, including mentoring, career development, intra-personal skills, training and annual performance appraisals. Formulates and maintains QC objectives and coordinates objectives with manufacturing procedures in cooperation with other managers to maximize product reliability and minimize costs Institutes and manages continuous improvement programs throughout Facet Plans, develops and implements departmental policies and goals Ensures corporate wide compliance to current QSRs, ISO and EN regulations Direct all quality related investigations, change control, and audits Manages all regulatory files, including DHR, MDR, CE Technical Files, 510k, Product/Establishment Registration, etc. Responsible for MDR investigations/FDA reporting and EU vigilance Coordinates ISO 13485, MDD and JPAL/JGMP certification activities and functions. Acts as management representative of quality system, including official correspondent with FDA and Sekinin-Gijutsu-Sha for JPAL requirement. Oversees preparation and maintenance of 510k (s) and CE Mark Technical Files Establishes statistical sampling procedures and record keeping systems. PROBLEM SOLVING DECISION MAKING Applies comprehensive knowledge of quality assurance/regulatory requirements to the completion of significant and difficult assignments Ability to be proactive in the identification and solution to business issues Ability to deal with quality issues proactively both tactically and strategically Ability to define problems, collect data, establish facts, and draw valid conclusions ACCOUNTABILITY Identifies, initiates, plans, conducts, reviews, evaluates and supervises daily tasks with minimal functional guidance Interprets and applies corporate policies Departmental budget (operating and capital) Strives for continual improvement in all responsible areas Knowledge of materials, methods, techniques, practices, tools equipment and processes required to effectively execute tasks in manufacturing SUPERVISORY RESPONSIBILITIES Quality Engineers Quality Engineering Supervisor Quality Technicians EDUCATION Minimum of BS in engineering or related field EXPERIENCE Minimum of 15 years related quality/regulatory management experience in a medical device or ISO environment Extensive knowledge and experience with QSRs, ISO and EN regulations Experienced with process improvement, SPC and other statistical process control/dock to stock methods Has managed new product start-ups and launches from a quality/regulatory perspective Fundamental knowledge of business metrics CERTIFICATES, LICENSES, REGISTRATIONS ASQ CQE or CQA Six Sigma experience, Black Belt certification desired