Laser Technology, Inc

advertisement

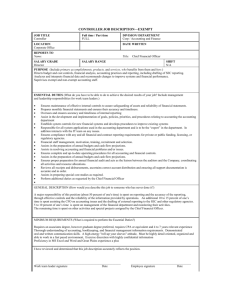

LASER TECHNOLOGY, INC. Job Description Job Title: Department: Reports To: Prepared By: Prepared Date: Quality Manager/Manufacturing Engineer Production and Quality Control Director of Operations Chris Budden 03/2012 SUMMARY Provides day-to-day technical and engineering support to manufacturing processes, and assists in coordinating, monitoring and improving manufacturing process efficiencies. As the Company’s Quality Manager, manages quality control department including incoming and outgoing inspection process. Facilitates release to production on all new product introductions. These tasks will be accomplished by performing the following duties: ESSENTIAL DUTIES AND RESPONSIBILITIES include the following. Other duties may be assigned. Analyzes, addresses and solves technical questions, problems or incidents on the manufacturing floor, immediately responding to any technical issues that threaten production flow. Coordinates with Manufacturing Operations team to develop, evaluate, and improve manufacturing methods. Assists Manufacturing Operations team in the generation, monitoring, routing and closing of manufacturing floor work orders, including out-sourced processes and material rework. Analyzes and plans work force utilization, space requirements, workflow, and design layout of equipment and workspace for maximum efficiency. Makes recommendations to Manufacturing Operations management team and assists in implementation of agreed upon changes. Confers with Engineering and design staff concerning current and future product design, tooling and fixtures needed to ensure efficient production methods. Actively manages and participates in new product introduction from Engineering to manufacturing floor, creating documentation and facilitating assembly and training procedures. Confers with purchasing department and vendors to determine and evaluate incoming material specifications and ensures all material will allow the finished manufactured product to meet defined specifications and overall quality standards. Works with purchasing to assess incoming material quality and vendor performance. Oversees return of unacceptable material to vendor and provides necessary technical support for such returns. Assists Manufacturing Operations team in estimating production times, staffing requirements, and related costs to provide information for management decisions. Confers with management, engineering, and other staff regarding manufacturing capabilities, efficiency, and quality. Applies statistical methods to estimate future manufacturing requirements and potential. Monitors in-process and finished product quality to ensure quoted specifications are met. Interfaces with accounting to provide feedback on manufacturing variances and production flow issues. May act as the Management Representative for the Company’s ISO Quality Management system. Company’s ISO Management Representative, takes on the following responsibilities and authority: Ensures that the processes needed for the quality management system are established, implemented and maintained. Reports to management on the performance of the quality management system and any need for improvement. Ensures the promotion of awareness of customer requirements throughout the organization. SUPERVISORY RESPONSIBILITIES Manages Quality Control Supervisor and quality control staff. Is responsible for the oversight, direction, coordination, and evaluation of the Manufacturing Quality Control department. Carries out supervisory responsibilities in accordance with the organization's policies and applicable laws. Responsibilities include interviewing, hiring, and training employees; planning, assigning, and directing work; appraising performance; rewarding and disciplining employees; addressing complaints and resolving problems. QUALIFICATIONS To perform this job successfully, an individual must be able to perform each essential duty satisfactorily. The requirements listed below are representative of the knowledge, skill, and/or ability required. Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions. EDUCATION and/or EXPERIENCE Minimum of 5 years experience in a technical manufacturing environment. 3 + years experience in quality control including inspection, production planning, and forecasting. Demand flow technology implementation and 6 Sigma or TQM experience required. ISO 9001 experience preferred. Experience with SQL, Microsoft Access, Excel, Word required. Experience with Root Cause analysis utilizing various methods to identify issues and solutions to manufacturing problems. Works well with production assemblers, technicians, and operations and engineering personnel in a team environment to meet company goals. Strong familiarity with Quality Management processes and methods with the ability to contribute towards development of a strong quality management system. Strong, data collection, analysis and organizational skills helping to identify critical path issues and recommended solutions. REASONING ABILITY Must have excellent communication, coaching and mentoring skills. PHYSICAL DEMANDS The physical demands described here are representative of those that must be met by an employee to successfully perform the essential functions of this job. Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions.