University of Kent at Canterbury

advertisement

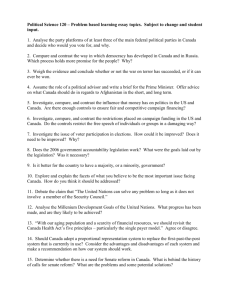

UNIVERSITY OF KENT – CODE OF PRACTICE FOR QUALITY ASSURANCE MODULE SPECIFICATION TEMPLATE 1 The title of the module: 2 The Department which will be responsible for management of the module Plant Technology School of Advance Technician Engineering 3 The Start Date of the Module September 2008 4 The number of students expected to take the module 30 5 Modules to be withdrawn on the introduction of this proposed module and consultation with other relevant Departments and Faculties regarding the withdrawal 6 The level of the module Certificate [C] 7 The number of credits which the module represents 15 8 Which term(s) the module is to be taught in (or other teaching pattern) Semester 1 9 Prerequisite modules: None 10 The programmes of study to which the module contributes Foundation Degree in Engineering, HNC in Engineering 11 The intended subject specific learning outcomes and, as appropriate, their relationship to programme learning outcomes To achieve this unit a student must: 1) Describe, interpret and compare procedures for the safe and effective testing and operation of plant. 2) Apply the Steady Flow Energy Equation to investigate the performance of plant and equipment. 3) Apply the principles of heat transfer to investigate the behaviour of plant processes. 4) Analyse and interpret the performance of power supply plant. These learning outcomes directly relate to the listed programme learning outcomes A2, A3, A4 & A5 of the programmes listed in section 10. 12 The intended generic learning outcomes and, as appropriate, their relationship to programme learning outcomes The following generic learning outcomes directly relate to the listed programme learning outcomes D31 of the programmes listed in section 10. 1) Communicate effectively with other people using visual, graphic, written and verbal means Latest version received 30/11/09 UNIVERSITY OF KENT – CODE OF PRACTICE FOR QUALITY ASSURANCE 13 A synopsis of the curriculum Operating and testing of plant: Safe operating procedures: pre start-up, start-up, operating and shut-down procedures. Permit to work, emergency procedures. Performance monitoring: collection and organisation of results and data. Monitoring of flow process variables, eg temperature, pressure, volume flow, recognition of abnormal conditions, corrective action and quality control. Performance testing: Measurement, comparison and evaluation of measured criteria such as power, efficiency, heat loss, power factor, slip with accepted norms. Steady flow energy equation (SFEE): Derivation of SFEE: the first law of thermodynamics, and the derivation of the Steady Flow Energy Equation using principles of conservation of energy, mass flow, internal energy, work flow, enthalpy, kinetic energy, potential energy. Application of SFEE to plant: practical application of the SFEE to process plant, including boilers, turbines, pumps, superheaters and compressors. Assumptions made in the application of the SFEE, negligible quantities, throttling and boiler efficiency Heat transfer: Heat transfer through walls, Overall heat transfer coefficient (U) and k vales for solid and composite walls, Newton’s and Fourier’s theories. Determination of heat transfer and interface temperature including boundary layer effects on single walls, comparison of refrigerator casing with furnace walls. of performance of condensers. Pipes: heat transfer in plan and composite pipes, k values on thick and thin cylinders. Comparison of lagged and unlagged pipes, optimum lagging thickness. Heat exchangers: examination of types ;(direct injection, parallel and counter flow) thin cylinder heat transfer, losses and performance coefficients. 14 Power supply equipment: Diesel engines: operating principle, 2 and 4 stroke cycles, performance and output, compression ratios, brake mean effective and indicated pressures, indicated power and efficiency, thermal , relative air standard efficiency. Specific fuel consumption. Application and evaluation of the Morse Test. Steam turbines: measurement of power output, effect of temperature change across turbine, impulse and reaction principles, pass out, back pressure and condensing turbines, avoidance of wet steam, limitations on efficiency. Gas turbines: single and double shaft, regeneration and reheat, efficiency,(with and without regeneration)assignments, economics of gas turbines. Electric motors: DC motors – shunt, series and compound wound, torque and speed equations, speed control, torque, AC motors – three phase and single phase, induction motors, synchronous speed, slip, operating characteristics, load testing, efficiency and power factor. Indicative Reading List Eastop T D, McConkey A – Applied Thermodynamic Solutions Manual (Longman, 1993) Eastop T D, McConkey A – Applied Thermodynamics for Engineering Technologists(Longman Press, 1997) Hughes E, Smith I – Electrical Technology (Longman, 1995) Latest version received 30/11/09 UNIVERSITY OF KENT – CODE OF PRACTICE FOR QUALITY ASSURANCE 15 Learning and Teaching Methods, including the nature and number of contact hours and the total study hours which will be expected of students, and how these relate to achievement of the intended learning outcomes The module is designed to offer a broad-base of study of key scientific principles, covering both mechanical and electrical concepts associated with the design and operation of engineering systems. It aims to provide the basis for further study in specialist areas of engineering. Students will be expected to spend 150 hours of study apportioned as follows: 50 contact hours: involving a mix of taught lessons to explain the theoretical and practical aspects of the module 20 hours assessment and revision 80 hours private study 16 Assessment methods and how these relate to testing achievement of the intended learning outcomes The module will be assessed by both coursework and examination. The coursework (70%) comprises 2 equally weighted assignments and practical work. The end examination (30%) will be 3 hours long and will assess the logical understanding of the principles studied in the SLOs. Subject specific learning outcomes 1) Describe, interpret and compare procedures for the safe operation and testing of plant. Assessment Criteria 2) Apply the Steady Flow Energy Equation to investigate plant performance. 3) Use the principle of Heat Transfer to investigate the behaviour of plant processes. 4) Analyse and evaluate the performance of power supply plant. Latest version received 30/11/09 Establish and describe appropriate safe procedures for the operation and testing of plant.. Collect, collate and interpret data and results to generate written reports. Evaluate test results by comparison with established performance norms. Using the First Law of Thermodynamics, establish the SFEE from first principles. Quantify and specify the assumptions used in applying the SFEE to plant. Derive specific equations incorporating the assumptions. Use the equations to investigate specific plant items. Use formulae involving U and k to investigate heat transfer through walls Recognise the effects of boundary layers. Use heat transfer formulae to evaluate heat exchanger performance. Investigate heat losses through lagged and unlagged pipes. Investigate diesel engine performance criteria. Investigate steam turbine performance criteria Analyse the performance criteria of a gas turbine. Investigate the performance of electric UNIVERSITY OF KENT – CODE OF PRACTICE FOR QUALITY ASSURANCE motors. Generic learning outcomes Analyse and solve problems using appropriate methods. Latest version received 30/11/09 Correct application and presentation of appropriate methods and techniques to solve practical problems. UNIVERSITY OF KENT – CODE OF PRACTICE FOR QUALITY ASSURANCE 17 Implications for learning resources, including staff, library, IT and space. This module will be taught and supported by appropriately qualified lecturers who have experience in supervising research projects. All the items stated in the Indicative Reading List are available at the Horsted Centre, Learning Resource Centre IT suites which all allow Internet, On-line T.I. Onestop Technical Index Facility. Practical sessions will take place in the Electrical Lab which is fully equipped to accommodate the requirements of learning outcomes. A full-time Technician supports the laboratory activities. 18 A statement confirming that, as far as can be reasonably anticipated, the curriculum, learning and teaching methods and forms of assessment do not present any non-justifiable disadvantage to students with disabilities The learning outcomes, teaching and learning methods and assessments are accessible to and achievable by all students. Specific requirements for disabled students to undertake work placements will be made as appropriate. Any student with disabilities will not face any foreseen disadvantage or difficulties that cannot be reasonably addressed. Statement by the Director of Learning and Teaching: "I confirm I have been consulted on the above module proposal and have given advice on the correct procedures and required content of module proposals" ................................................................ Director of Learning and Teaching .............................................. Date Statement by the Head of Department: "I confirm that the Department has approved the introduction of the module and will be responsible for its resourcing" ................................................................. Head of Department Latest version received 30/11/09 .............................................. Date