Chromatography

advertisement

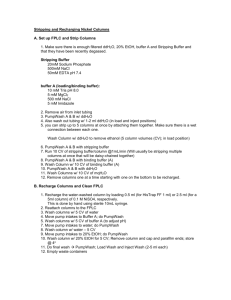

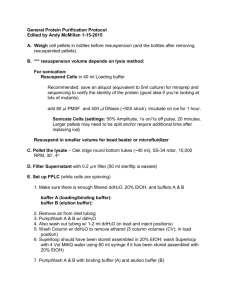

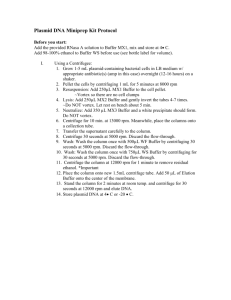

P. Fajer page 1 of 3 Chromatography Waters HPLC Filtering All DDW, and buffers must be filtered and deareated before use. All samples should be filtered before placing on the column. Priming Disconnect the column. Waters pumps must be primed (filled with solution) before the use. Remove all bubbles from the supply line using the 3-way cock and syringe. Force the solution with the syringe while slowly running the pump. Shut off the syringe flow – connect gravity-fed supply lines and the pump. Check each pump in turn whether it delivers the same volume. All the lines have to be filled with the liquid before connecting to pumps. Otherwise, the air will get into the column. Pump Controller For the gradient controller to control the pumps, the pump speed has to be set to 0. UV/Vis Inject small volume of your sample to make sure that the recorder/UV monitor are working and registering the concentration. Connect the National Instruments board and computer. Call up the chromatography software. Superdex Chromatography - $1100 to replace Filter and dearate Max sample size should be 250 l DO NOT EXCEED A FLOW RATE OF 0.5 MLS/MIN, turn the pump on at 0 ml/min and adjust upward. If the column has EtOH in it then do not exceed 0.4 ml/min If the column is in 20% EtOH rinse with at least 2 void volumes of DDW before use. After column use, rinse column with at least 2 void volumes of DDW before placing in 20% EtOH. Backpressure with EtOH tends to be higher, therefore reduce the flow rate when storing the column in EtOH buffer. To store the column, attach the black rubber tube to column outlet, let it fill completely with liquid (hold upright so that it says filled to the brim), disconnect the inlet tube and connect the inlet with outlet. Make sure that both ends are tightly connected and have no air. 533564875 2/16/2016 10:20:00 AM2/16/2016 10:20:00 AM P. Fajer page 2 of 3 MonoQ Chromatography - $1100 to replace Filter and dearate The column has to be equilibrated with the low ionic strength buffer. The pressure cannot exceed 750 psi Clean with 2M salt immediately after the usage Wash out salt with DDW HPLC with C-8 Make sure that the column is filled with 100% of solution A (.1% TFA). Load Sample. Start Program 11, and run for 7 minutes. Start linear gradient. Program 6, 1 ml per minute for 20 minutes with Abs @ 280nm Run in 100% of solution B for 10 minutes. P.S. Don't forget to collect your fragments. Low pressure Econo-Pac CM cartridge Type: Weakly acidic cation exchanger Bed volume: 5 ml Protein binding capacity: > 125 mg hemoglobin Recommended flow rate: 0.5 - 3 ml/min Maximum flow rate: 6 ml/min Recommended storage: 20 mM phosphate, pH 6.8 with 0.05% NaN3; or 20% v/v ethanol solution Preparing a Cartridge For Use Set pump flow rate to 2.0 ml/min. Wash the cartridge with degassed low salt buffer for 2 minutes at 2 ml/min. Wash the cartridge with degassed high salt buffer for 10 minutes at 6 ml/min. A small amount of air may remain just above the upper frit and in the inlet nozzle of the cartridge. Invert the cartridge so that the arrow points upward, allowing air to be expelled into the cartridge and out through the outlet nozzle. Equilibrate the cartridge with low salt buffer for 10 minutes at 6 ml/min. Invert the cartridge so that the cartridge points downward. Reduce the flow rate to 2 ml/min. Sample Preparation All samples should be filtered through a 0.45 m filter. 533564875 2/16/2016 10:20:00 AM2/16/2016 10:20:00 AM P. Fajer page 3 of 3 General Purification Protocol Both samples and buffers should be degassed and filtered through a 0.45 m filter. An appropriate starting point for separation of many samples is a linear gradient from 0 to 1.0 M NaCl over 50 minutes at a flow rate of 2.0 ml per minute. The separation can then be optimized by changing the flow rate and gradient profile. At the end of each run the cartridge can be regenerated at 6 ml/min with 10 - 20 ml of buffer containing 1.0 M NaCl. Follow this with 20 ml of starting buffer. Return to the desired flow rate and proceed with the next separation. Cleaning the Cartridge After repeated use, an ion exchange cartridge may require thorough cleaning and regeneration to remove bound contaminants. Most bound contaminants may be removed by following the procedure below: Wash the cartridge with 20 - 30 ml of 1 M NaOH at 1 ml/min. Wash with 50 ml of deionized water or starting buffer (6 ml/min). Wash with 25 ml of high salt buffer (6 ml/min). Equilibrate the cartridge with at least 25 ml of starting buffer (6 ml/min). If bound contaminants persist after following the procedure above, use one or both of the alternative procedures below: Wash alternative 1 Perform step 2 above. Wash with 50 ml of 20% ethanol solution. Then continue with steps 2-4 above. Wash Alternative 2 Perform step 2 above. Wash with 25 ml of 75% acetic acid, or 1.0 M HCl. Then continue with steps 2-4 above. 533564875 2/16/2016 10:20:00 AM2/16/2016 10:20:00 AM