Mechanical analysis and optimization of a

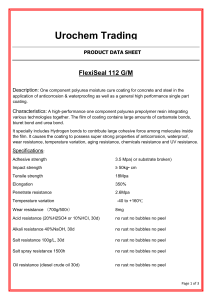

advertisement

Mechanical analysis and optimization of a microcantilever sensor coated with a solid receptor film Genki Yoshikawa* International Center for Materials Nanoarchitectonics (MANA), National Institute for Materials Science (NIMS), 1-1 Namiki, Tsukuba, 305-0044, Japan Supplementary Material Dependence of cantilever deflection on the thickness and Young’s modulus of a coating film The deflection of a cantilever varies according to the given parameters of the cantilever and coating film. Figure S1 shows the dependence of cantilever deflection on the thickness and Young’s modulus of coating film with various parameters. Note that all figures in Fig. S1 are plotted with same scales in both horizontal and vertical axes. It is found that the position of optimum coating thickness, with which the deflection peak is observed, is not affected by the length, width, or the amount of induced strain in the coating film as confirmed in Figs. S1(a)~(d) and equation (S2), whereas these parameters determine the amount of deflection. As seen in Figs. S1(e) and (f), the thickness of cantilever and Poisson’s ratio of coating film affect both optimum thickness and deflection although the influence of Poisson’s ratio is rather small in the present case. By changing the cantilever material (having different Young’s modulus or Poisson’s ratio), the optimum coating thickness and amount of deflection are also varied as shown in Figs. S1(g)~(i). 1 Calculation and analysis of the optimum coating thickness In order to find the optimum coating thickness values, the derivative of the deflection with respect to the coating thickness is calculated as follows: 1 E w t (1 ) 2 Ec wc tc (1 f ) 2 c f f f 4tf 4 tc 6t f tc E w t (1 ) Ec wc tc (1 f ) f f f c d z 2 3 2 E w t (1 ) E w t (1 ) E w t (1 ) 3l f f f f c c f 4 f f f c cc2 6tc (t f tc ) 2t f dt f E w t (1 ) E w t (1 ) c c c f f f f c Ec wc tc (1 f ) 2 E f w f t f (1 c ) 2 Ec wc tc (1 f ) 2 4tf 4 tc 6t f tc E w t (1 ) Ec wc tc (1 f ) c f f f (S1) By solving (dΔz/dtf) = 0 for tf, five solutions are obtained. Among them, the following one yields the optimum coating thickness (tf-op) with reasonable values: t f op tc X 1/3 X 1/3 1 2 (S2) where X 2 Ec wc 1 f E f w f 1 c 2 Ec wc 1 f E f w f 1 c E w 1 E c c f f w f 1 c (S3) which can be simplified in the case of wc = wf, using Uc = Ec(1-νf) and Uf = Ef(1-νc): X 2U c U f 2 U c U c U f Uf (S4) In the case of νc ~ νf, X can be approximately simplified further as follows: X 2 Ec E f 2 Ec Ec E f Ef (S5) Note that equations (S2) and (S4) are same as equations (5) and (6) in the text, respectively. Equations (S2) ~ (S5) indicate several important aspects of the optimum coating thickness (tf-op) as follows: 1) tf-op is proportional to the cantilever thickness (tc). 2) tf-op is determined by widths (wc and wf), Young’s moduli (Ec and Ef), and Poisson’s ratios (νc and νf) of the cantilever and coating film as well as tc. 3) tf-op does not depend on the length (l) or the amount of the induced strain in the coating film (εf). 4) In the case of wc = wf, tf-op is no longer dependent on the width and determined only by Young’s 2 moduli (Ec and Ef), Poisson’s ratios (νc and νf), and tc. 5) Further, in the case of νc ~ νf, tf-op depends only on the two parameters; Young’s moduli (Ec and Ef) and tc. 6) In the case of Uf ~ Uc, X approaches ~1, resulting in tf-op ~ tc/2. 7) The smaller (larger) value of Ef leads to the smaller (larger) value of X, resulting in the higher (lower) value of tf-op owing to the dominant contribution of X-1/3 term in equation (S2). Using equations (S2) as well as (S3) ~ (S5), one can readily find the optimum coating film thickness (tf-op) under given conditions and can check its dependence on the relevant parameters. For example, the dependence of optimum coating thickness on Young’s modulus of coating film (Ef) is plotted in Fig. S2. It is found that the optimum coating thickness is higher (lower) for a coating film with smaller (larger) Young’s modulus (cf. Figs. 4, S1, S2, and the above point 7). Thus, the optimum coating thickness can be attributed to a specific point where the additional stiffness due to the additional thickness of coating film becomes dominant over the effective force induced by the entire coating film. It should be noted that equation (S2) results in a non-numerical tf value in the case of Ecwc(1-νf) > Efwf(1-νc) or Uf > Uc or Ef > Ec because of negative values appearing in the square roots in equations (S3) ~ (S5). In such a case, one has to plot the deflection of cantilever as those shown in Fig. S1 to find the optimum coating thickness. 3 4 FIG. S1. The dependence of cantilever deflection on the thickness and Young’s modulus of coating film with various parameters. All figures are plotted with same scales in both horizontal and vertical axes. The legend is shown only in (a) and (g), whereas the same color corresponds to the same Young’s modulus in all cases. The other parameters used in each case are summarized in Table SI. The assumed material of cantilever is indicated in each title with the parameter varied from those in the case of (a) in the parenthesis. The widths of the cantilever and coating film are set at the same value w (= wc = wf). (a) ~ (f) are based on the parameters of Si cantilever (Ec = 170 [GPa] and νc = 0.28). (g) is based on a different Poisson’s ratio (νc = 0.40) than that of Si. (h) and (i) are based on the parameters of SU-8 cantilever (Ec = 5 [GPa] and νc = 0.30). 5 TABLE SI. The parameters used in Fig. S1. The parameters varied from those in the case of (a) are described in bold characters with gray highlight. (a) (b) (c) (d) (e) (f) (g) (h) (i) Ec (GPa) 170 170 170 170 170 170 170 5 5 νc 0.28 0.28 0.28 0.28 0.28 0.28 0.40 0.30 0.30 νf 0.30 0.30 0.30 0.30 0.30 0.40 0.30 0.30 0.30 tc (μm) 1 1 1 1 7 1 1 1 7 l (μm) 500 2000 500 500 500 500 500 500 500 w (μm) 100 100 500 100 100 100 100 100 100 εf (ppm) 10 10 10 100 10 10 10 10 10 6 FIG. S2. Dependence of optimum coating thickness (tf-op) on Young’s modulus of coating films. Pink, blue, and light blue lines correspond to cantilevers made of silicon (Ec = 170 [GPa], νc = 0.28), while yellow line to the cantilever made of SU-8 (Ec = 5 [GPa], νc = 0.30). Poisson’s ratio of coating film (νf) is set at 0.40 for blue line and at 0.30 for pink, light blue, and yellow lines. The optimum thicknesses of PMMA, PU, and CMC found in Fig. 4 are indicated as black, red, and green dots. 7