1.1 To lay down the procedure for development and validation of

advertisement

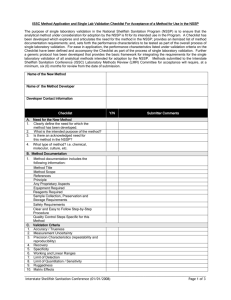

1.0 PURPOSE: 1.1 2.0 SCOPE: 2.1 3.0 Senior Executive – QC ACCOUNTABILITY: 4.1 5.0 This procedure is applicable for Development and Validation of Analytical Method for equipment cleaning. RESPONSIBILITY: 4.1 4.0 To lay down the procedure for development and validation of analytical method for equipment cleaning. Manager - QC PROCEDURE: 5.1 Review the written cleaning procedure to determine what cleaning agents are used, such as water, alcohol, etc. 5.2 From information about the target analyte (least soluble active drug substance), determine what kind of analytical procedure will be used to measure any residual of the target analyte after cleaning. As per following table. ANALYTICAL TECHNIQUE SELECTION FOR CLEANING VALIDATIONS Target Analyte UV-Visible active drug where no other components of the product are UVVisible active UV-active drug where other components of the product are UV active Method UV spectroscopy Reason 1. Sensitivity 2. Selectivity because of knowledge of matrix HPLC UV inactive drugs that are volatile or for which volatile derivatives can be prepared GC UV inactive drugs that are acidic or basic and for which UV, HPLC, AA and GC are not applicable Titration 1. Sensitivity, if the correct wavelength is chosen. 2. Selectivity based on separation of analyte from matrix. 1. Sensitivity if correct detector and detector parametes are chosen 2. Selectivity if proper chromatography is employed 1. Sensitivity if dilute enough titrants are used (0.001N or 0.001N) 5.3 Develop and validate the method of choice as per following table. Analytical Technique UV spectroscopy Analytical Technique HPLC GC Minimum Validation Components Precision Linearity Limit of detection Limit of quantitation Swab recovery Rugged ness Solution stability Minimum Validation Components Linearity Accuracy Limit of detection Limit of quantitation Specificity Solution stability Linearity Accuracy Titration Limit of detection Limit of quantitation Specificity Solution stability Limit of detection Limit of quantitation Solution stability 5.3 Prepare an analytical method that defines cleaning validation method. 5.4 Prepare analytical method validation protocol as per the Annexure I 5.5 Assign the protocol number as per the Quality assurance SOP No.: xxxxx 5.6 Carry out the sampling for swab recovery as per sampling SOP no. xxxxx 5.7 Carry out the validation as per cleaning validation method. 5.8 Based on the data, prepare a cleaning validation report as per the Annexure II END OF DOCUMENT