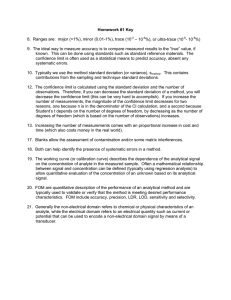

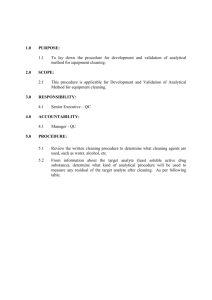

Quality of Analytical Data and Validation I GAA Septiari Instrumental Signals ▪ For quantitation of a given analyte in a certain sample, an instrumental signal is measured for the analyte. ▪ The instrumental signal normally increases linearly with concentration (amount) of the analyte in the sample ▪ The classical way to determine the relation is to measure the instrumental signal for a series of standard solutions containing exactly known concentrations of the analyte and to plot the signals of these versus concentration. ▪ The resulting linear relationship is termed a standard curve or a calibration curve and the entire procedure is termed calibration. Validation ▪ Validation is the process to demonstrate that an analytical procedure is suitable for its intended purpose. ▪ New analytical methods must be validated before they can be applied. ▪ Analytical procedures: • Identification tests • Quantitative tests for impurities • Limit tests for impurities • Quantitative tests (assays) of the active moiety in samples of drug substance or drug product or other selected component(s) in the drug product Validation • Analytical method validation forms the first level of QA in the laboratory • An analytical result must always be accompanied by an uncertainty statement, which determines the interpretation of the result • Validation is thus the tool used to demonstrate that a specific analytical method actually measures what it is intended to measure, and thus is suitable for its intended purpose When do you need validation? ▪ Validation is required for any new method -> revalidation ▪ When a new method is being developed ▪ Validation of a new analytical method is typically done at two levels. ▪ The first is pre-validation, aimed at fixing the scope of the validation. ▪ The second is an extensive, ‘‘full’’ validation performed through a collaborative trial or inter-laboratory study Validation ▪ The purpose of an analytical method is the delivery of a qualitative and/or quantitative result with an acceptable uncertainty level -> measuring uncertainty ▪ In practice, method validation is done by evaluating a series of method-performance characteristics, such as Precision, trueness, selectivity/specificity, linearity, operating range, recovery, limit of detection (LOD), limit of quantification (LOQ), sensitivity, ruggedness/robustness and applicability Analytical Characteristics in Validation Validation ▪ Which performance criteria have to be evaluated depends also on the purpose of the method. Different ICH/USP guidelines are set up for: (1) identification tests; (2) impurity tests; and, (3) assay tests ▪ An identification test ensures the identity of an analyte in a sample, by comparing it to a known RM. ▪ An impurity test is intended to confirm the identity of (limit impurity test) or to accurately quantify (quantitative impurity test) an impurity, defined as an entity ‘which may normally not be present’. ▪ An assay test finally applies to the major component or active ingredient in a sample and quantifies the drug substance as such, as a whole, or the drug substance in a drug product. Validation of The Different Types of Analytical Procedures Specificity ▪ The specificity of an analytical method is defined as ‘the ability to assess unequivocally the analyte in the presence of compounds that may be expected to be present (impurities, degradation products, matrix, etc.) ▪ Analytical methods with high selectivity provide measured instrumental signals solely from the target analyte. ▪ High (or sufficient) selectivity is vital for analytical methods. ▪ If an analytical method lacks specificity, one or several matrix components in the sample may contribute to the instrumental signal and the measurements may not provide an exact result. Specificity ▪ Specificity is tested as part of the validation procedure for identification tests, determination of impurities, and assay. ▪ For identification methods (qualitative analysis), the ability to select between compounds of closely related structures that are likely to be present in real samples should be demonstrated. ▪ This should be confirmed by obtaining positive results (identification) from samples containing the analyte, coupled with negative results from samples that do not contain the analyte. Specificity ▪ For quantitative methods of pharmaceutical ingredients and pharmaceutical preparations: ▪ This can be done by spiking the pharmaceutical ingredient or preparation with appropriate levels of impurities or excipients and demonstrate that the assay result is unaffected by the presence of these extraneous materials. Specificity Accuracy ▪ The accuracy of an analytical method is defined as ‘the closeness of agreement between the value which is accepted either as a conventional true value or an accepted reference value, and the value found’. ▪ In the case of the assay of a pharmaceutical ingredient, accuracy may be determined by application of the analytical procedure to a substance of known purity, for example a certified reference substance or a substance with a similar high quality. Accuracy ▪ In an assay of API in a pharmaceutical preparation, accuracy may be determined by application of the analytical procedure to synthetic mixtures of the preparation (drug-free) to which known amounts of the drug substance (e.g. a CRS) have been added. ▪ Another possibility of establishing accuracy is to compare the results with another independent well-characterized method for which accuracy has been documented CRS : Chemical Reference Substance is a highly purified and well-defined quality of the analyte. Precision ▪ The precision of an analytical procedure is defined as ‘the closeness of agreement (degree of scatter) between a series of measurements obtained from multiple sampling of the same homogenous sample under the prescribed conditions’ ▪ Precision is usually expressed as the standard deviation (s) or the relative standard deviation (%RSD) of the mean (x) of a series of measurements: Precision Another measure of precision is the confidence interval, in which all measurements fall with a certain probability or confidence level 1-a (a is often 0.05, giving a probability here of 95%) Precision ▪ Precision is normally considered at three different levels: • Repeatability • Intermediate precision • Reproducibility Precision ▪ The repeatability is the precision under the same operating conditions over a short interval of time. ▪ Normally, the same operator with the same equipment carries out the measurement repeatedly within one day within the same laboratory. ▪ Intermediate precision expresses within-laboratories variations of measurements, as on different days, or with different analysts or equipment. ▪ Reproducibility expresses the precision of a procedure between different laboratories in a collaborative study. Detection Limit ▪ The detection limit (DL) of an analytical method is defined as ‘the lowest amount of analyte in a sample that can be detected, but not necessary quantitated as an exact value’ under given experimental conditions. ▪ The detection limit is usually expressed as analyte concentration in the sample. ▪ The terms limit of detection (LOD) and lower limit of detection (LLOD) are used as alternatives to detection limit. ▪ For instrumental methods, calculation of the detection limit can be based on the signal-to-noise ratio (S/N). Detection Limit ▪ The detection limit (DL) is defined as the concentration providing an instrumental signal two, three, or three-point-three times the noise level, thus providing a signal-to-noise ratio (S/N ratio) of 2, 3, or 3.3. ▪ The latter is the factor used in the ICH guideline: DL = 3.3 × 𝜎/S ▪ 𝜎 is the standard deviation of the response (representing the noise level) ▪ S is the slope of the calibration curve, which is used to convert the signal to a concentration Quantitation Limit ▪ The quantitation limit (QL), also termed the limit of quantitation (LOQ) or the lower limit of quantitation (LLOQ) of an analytical method, is defined as ‘the lowest amount of analyte in a sample, which can be quantitatively determined with suitable precision and accuracy’. ▪ This parameter should be estimated for assays for low levels of analytes and particularly for the determination of impurities and/or degradation products. Quantitation should not be performed below this limit. The quantitation limit is defined as the concentration of analyte providing a signal-to-noise ratio of 10: ▪ QL = 10 × 𝜎/S Linearity and Range ▪ The linearity of an analytical method is defined as ‘its ability (within a given range) to obtain test results, which are directly proportional to the concentration (amount) of analyte in the sample’ Linearity and Range ▪ For establishing linearity, standard solutions or calibration samples covering the entire range are analysed ▪ For assay (quantitation) of pharmaceutical ingredients and preparations, linearity should be established in the range of 80–120% of expected concentration, ▪ Quantitation of impurities the linearity should be established from 50% to 120% of acceptance criteria Robustness ▪ The robustness of an analytical method is defined as ‘a measure of its capacity to remain unaffected by small, but deliberate variations in method parameters and provides an indication of its reliability during normal usage’ ▪ In the case of LC, examples of typical variations are: • Influence of variations of pH in the mobile phase • Influence of variations in the mobile phase composition • Different columns (different lots/or suppliers) • Temperature of the column • Flow rate of the mobile phase Robustness ▪ Thus, the performance of the method is tested with small changes in the parameters listed above, and the analytical results should be unaffected