ENVIRONcheck

Environmental Dust Monitor 107

OPERATING MANUAL

GRIMM Aerosol Technik GmbH & Co. KG

Dorfstrasse 9, D-83404 Ainring, Germany

Tel: 0049-8654-578-0

Fax: 0049-86540-578-35

E-Mail: sales@grimm-aerosol.com

www.grimm-aerosol.com

1

INDEX

1

1.1

2

INTRODUCTION

6

Important Notes for the Customer

6

DUST MONITOR SYSTEM ENVIRONCHECK 107

8

2.1

Introduction to the legal monitoring principals

9

2.2

Operating Principle

9

2.3

Sampling Technology

10

2.4

Mass Measurement Correlation

10

2.5

Factory Calibration

10

2.6

Dust Mass Correlation

11

3

SYSTEM OPERATION

12

3.1

System Components

12

3.2

The Dust-Monitor Model 107

12

3.3

Operational Mode of Monitor 107 (only)

16

3.4

Key Functions

17

3.5

Print out from the Memory card

19

3.6

System Interruptions

19

3.7

Start-up

20

3.8

Factory calibration

22

3.9

Determination of the gravimetric-factor (C-Factor)

22

4

RS-232 INTERFACE AND ANALOG PORT

23

4.1

Concept of the RS-232-port

23

4.2

Construction of the Analog port

23

4.3

Communication Protocol Serial Com-Port

24

4.4

RS-232 Commands

24

4.5

RS-232-Data transmission

27

5

5.1

GESYTEC INSTRUCTION FOR ENVIRONCHECK 107

Differences to the STANDARD mode

28

28

2

5.2

6

6.1

7

GESYTEC- Operation

29

MEASUREMENT MODE

31

Determination of the “LOCAL” Density Correction factor

OUTDOOR HOUSING MODEL 165

31

32

7.1

General information

32

7.2

How to unpack and check for possible damage during transport.

32

7.3

Operating instruction of the 107

33

7.4

The Humidity and Temperature Sensor

33

7.5

Installation of the Dust Monitor 107 inside the housing 165

34

7.6

Installation of the sampling pipe 170M

34

7.7

Electrical Installation and Start-up Procedure

35

8

MAINTENANCE

36

8.1

General

36

8.2

Silicagel Exchange Procedure

36

8.3

ENVIRONcheck (Model 107) cleaning

37

8.4

Sampling pipe and filter holder

37

8.5

Filter exchange

37

9

DELIVERIES, WARRANTY AND TRANSPORTATION

38

9.1

Instrument Warranty

38

9.2

Service Policy

39

10

BUYING SOURCE

40

11

DIMENSION OF THE ENVIRONCHECK 107

41

3

TRADEMARKS

Trademarked names appear throughout this manual. Rather than list the names and entities that own

the trademarks at each mention of the trademark name, the publisher states that he is using the

names only for “editorial purposes” and to the benefit of the trademark owner with no intention of

infringing upon that trademark.

Submitting Comments

GRIMM values your comments and suggestions on this manual. Please use the comment sheet, on

the last page of this manual, to send us your opinion on the manual’s usability and any of your

suggestions for specific improvements, or to report any technical errors in this shall reconfirm your

valid contribution manual. In such a case send us your comment as email directly via the software link

and we! We shall reconfirm your valid contribution!

Copyright Notice

1995-2005, Grimm Aerosol Technik GmbH, Ainring Germany. All rights reserved.

Printed in Germany: Released: January 05 for Dust Monitor 107 and Weather Housing 165.

This document may not, in whole or in part, be copied, photocopied, reproduced, translated, or

reduced to any electronic medium or machine-readable form without prior consent in writing from

Grimm Aerosol Technik GmbH.

4

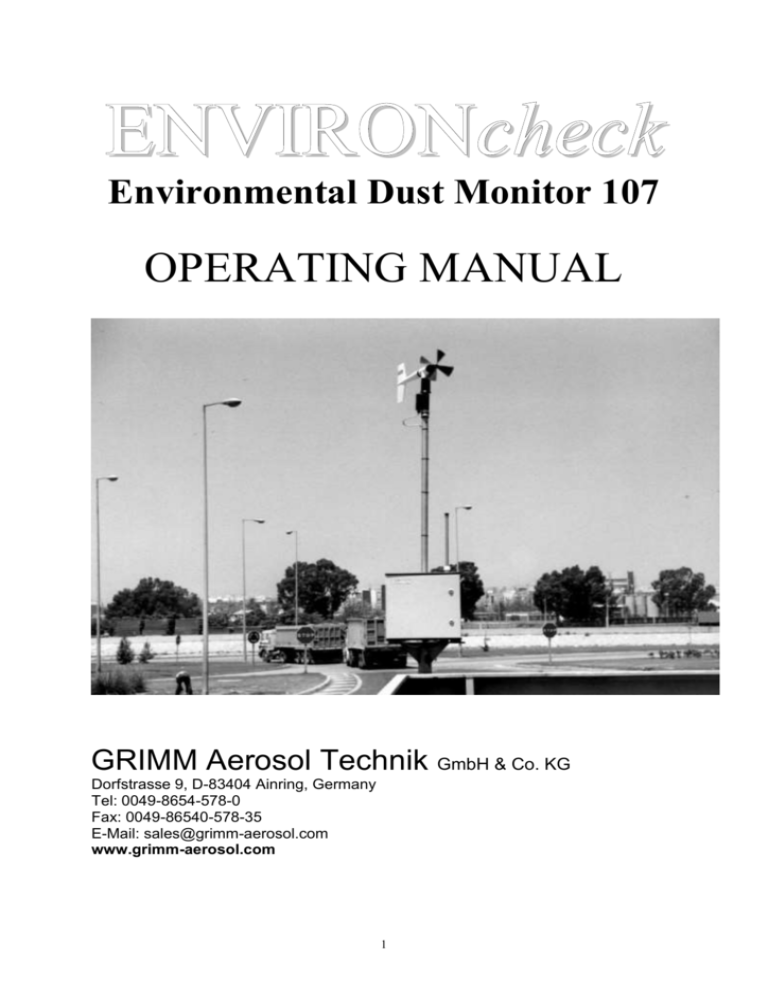

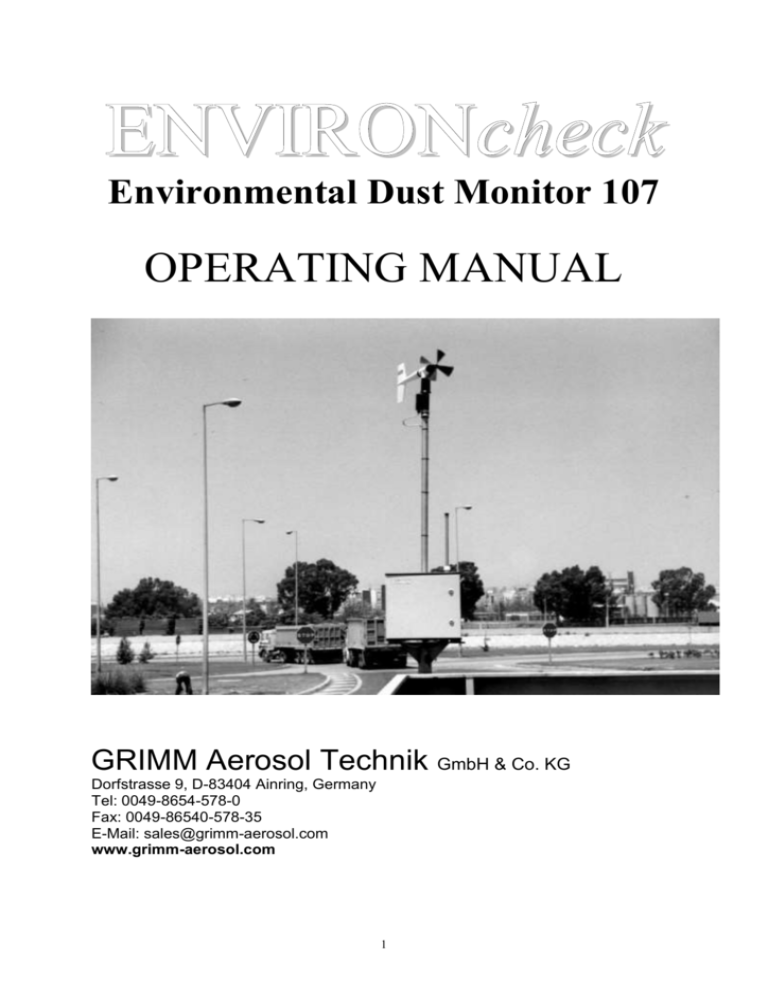

Above is a standard ENVIROcheck system, completely assembled shown,

below, for example, an automatic stand-alone system with climatic sensors

(installed in Spain)

5

1 INNTTRRO

OD

DU

UC

CTTIIO

ON

N

1.1

1.1.1

Important Notes for the Customer

Safety Regulations

The manufacturer refuses every direct or indirect liability if the user opens the instrument or manipulates

the instrument! This instrument is built and tested in accordance with EN-61010 (DIN VDE 0411 T1) to

assure proper protection of the electronic material and measurement function of the instruments. All units

have left the factory with regard to safeguarding in a perfect condition. In order to keep this state and to

guarantee a safe operation, the customer must follow the references and warning notes which are

contained in this manual.

If a safe operation is no longer possible, the instrument has to be taken out of operation and to be

protected against unintentional operation. A safe operation is not anymore possible,

- if the instrument shows visible harm,

- if the instrument does not work anymore,

- after longer storage under unfavourable conditions,

- after hard stress during transport.

If the instrument was stored or transported at low temperatures and an acclimatisation period is not kept

prior start up of minimum 1hour, the internal pump may not even start (due to possible inner

condensation). In this case the electronic protection fuse will activate and disconnect the instruments

power supply.

1.1.2

Laser Safety!

Caution! Optical laser class 3 B inside!

The instrument may only be opened by GRIMM trained service personnel.

During the opening of the laser unit, esp. the measuring chamber, a laser radiation of the class 3 B can

be released.

You will find references in the EN 60825 (DIN VDE 0837 T1), but also in the corresponding VBG 93

"Laser radiation" prevention regulation for possible accidental exposure!

All stickers shown are on the

bottom of the instrument and

WARN the operator for laser

light radiation in case the

covers of the instrument

have been dismounted!

6

1.1.3

Electric Safety

Before the first use of the instrument you need to check whether the main voltage is in the allowed

specifications.

The Lithium battery (SL-389; 3,6V; 1AH) on the digital circuit board is necessary to the operation

of the real-time clock. This battery must not be charged and only changed in an emptied state by an

authorised personal. The normal operation period is several years.

The recharge of the Lithium battery inside the memory card: (CR-2016 with 3V and 60mAh or CR2325 with 3 and 200mAh) is not permitted.

Fuses built into the instrument may only be changed by trained service personnel.

All fuses are to be replaced only by the same type!

Since the instrument has its internal electronic protection, the fuses will react

only at a serious fault. Caution!

1.1.4

Transportation

The instrument may be transported only in the original packing and in the switched off

mode. The aerosol inlet and output have to be closed with provided covers.

We reserve the right to change or to improve the instruments described in this manual without previous

announcement, simply in accordance to the technical progress. Therefore insignificant deviations

between the descriptions in this instruction and your measuring instrument are possible.

7

2 DUUSSTT MO

ON

NIITTO

OR

R SY

YS

STTE

EM

M ENVIRONC

CH

HE

EC

CK

K 107

The ideal instrument should be able to measure ALL the environmental dust requirements at the same

time. It should be easily transportable and operate with minimal labour & maintenance, for as long as

possible. It should automatically transmit daily, hourly, or updated results to networks or PC`s, store all

obtained results on an internal data logger for later presentation, report the instrument conditions,

especially if a failure occurs.

Finally, it should collect the measured sample on an EPA approved removable filter.

Some of the features of the ENVIRONcheck System are:

Single piece stainless steel construction, portable, with built in optical unit, able to measure PM 10, PM

2.5 and PM 1 at the same time

Particle sizing from 0,2µm to 20 µm

Particle mass from 1 to 1.500µg/m³

Data storage of days, weeks or month of test results

Keyboards or remote (via RS-232C) operation

Existing hardware and software accommodates a wide variety of accessory inputs

Automatic volume control and registration

Automatic humidity compensation

Removable filter for gravimetric confirmation, particle identification and chemical analysis

designed to be a stand-alone system for outdoor dust monitoring. The system can be operated

independently and does not need a protected environment, a shelter to operate.

8

2.1

Introduction to the legal monitoring principals

Regular data of the environmental dust conditions are legally required and reported by different

environmental agencies world wide to the public. These reports:

Follow US Clean Air Act requires PM 10 for EPA Part 50 for PM10 and now PM2.5

European Union Regulation 96/62 for monitoring in accordance to EN 12341 for PM-10 (and soon

PM-2.5)

Measure the particle size distribution in many different size channels, to obtain better knowledge

for sub-micron particle size distribution in addition to the dust mass distribution is more and

more required

2.2

Operating Principle

The particle size analyser /dust-monitor Model 107 described in this text is a small portable unit, used for

the continuous measurement of particles in the air (aerosols). These particles can be reported in various

modes. However, these measurements are determined in one of two basic modes, particle counts and as

Environmental mass as μg/m3. These measurements are reported for the various size distribution

channels.

All units of the 107 series use light-scattering technology for single-particle counts, whereby a

semiconductor-laser serves as the light-source. The scattered signal from the particle passing through the

laser beam is collected at approximately 90° by a mirror and transferred to a recipient-diode. The signal of

the diode is feed, after a corresponding reinforcement, a multi-channel size classifier. A pulse height

analyser then classifies the signal transmitted in each channel. These counts can be displayed and are

also stored in the data storage card and may be transferred via the RS 232 for further analysis. Without

data storage card the instrument has an internal memory size 80kb.

The ambient-air, to be analysed, is drawn into the unit via an internal volume-controlled pump at a rate of

1.2 litres /minute. The sample passes through the sample cell, past the laser diode detector and is

collected onto a 47-mm PTFE filter. The entire sample is collected on the PTFE filter, which can then be

analysed gravimetrically for verification of the reported aerosol's mass. Additionally, further chemical

analysis can be performed on the deposited residue. The pump also generates the necessary clean

sheath air, which is filtered and passes through the sheath air regulator back in to optical chamber. This is

to ensure that no dust contamination comes in contact with the laser-optic assembly. This particle free

airflow is also used for the reference-zero tests during the self-test.

9

2.3

2.3.1

Sampling Technology

Sampling Head

All particulate in the air passes the sampling inlet and enters vertically into the optical measurement cell.

This stainless steel pipe is polished and contains only a diluter for the humidification controller. The

sample head is designed as TSP sample head.

2.3.2

Measurement

During the measurement process all particles are categorised in their proper size and as being larger

than the largest size channel can only be categorised as such (i.e. particles classified with diameter > 20

um will be reported as such regardless of how much larger actually are). Practical experience has shown

that very few particles above 10 µm are in the ambient air and rarely anything above 20 µm has been

found (as count) over a 24h collection time.

2.3.3

Dehumidification System

The sample air is not heated to avoid loosing semi-volatile particles before measurement, all the sample

air is measure. This means below the dew point are sampling takes place as normal, however above 65%

relative humidity a dehumidification system is activated which feeds dry, clean air in a fixed ratio into the

sample pipe and assures NO condensation during measurement. An separate humidity and temperature

sensor controls at all time the parameters.

2.4

Mass Measurement Correlation

At the beginning of each measurement, the instrument initiates a self-test, which last approximately 30

seconds. The actual dust-measurement begins when the LCD displays the first result.

At that point the counts are stored and downloaded each 6 sec to the microprocessor in the monitor.

These counts at each channel are converted to volume and multiplied by a density algorithm. This

new mass distribution is than the base for the individual cut points set by the EPA accepted sampling

heads.

Subsequent results will be displayed every 6 seconds. The real-time dust-concentration measurement

data are transferred each minute to the removable data storage-card, if used. The data is also

available via the built-in RS-232 serial port. This data may be transmitted to an external computer or

printer. This data is available in intervals of every 6 seconds (fast-mode) or as an average value in a

chosen interval.

2.5

Factory Calibration

The factory calibration of each particle size analyser/dust monitor employs a three-step process.

2.5.1

Verification Calibration of Laser Optics

The first step on the factor calibration is to verify the instrument’s optics against a ”mother-unit” for proper

size classification and distribution.

2.5.2

Gravimetric Correlation Verification

Next a gravimetric correlation analysis is performed with stearin-acidity-aerosol. Using a gravimetricfactor of 1.0 for stearin aerosol is ideal, because of stearin’s unique physical characteristics, a density of

approximately 0.92 and a refractive index of approximately 1.45. A calibration certification is provided with

each instrument. The acceptable control limit is +/- 5%.

10

2.5.3

Optical Calibration Cross Reference

After a successful stearin calibration, a 3rd test is employed with spherical glass-beads. The glass beads

have a density of 2.8 and a refractive index of 1.36. The density-factor of 2.8 is coded into the

instrument’s hardware and used in the mathematical equation for the calculation and aerosol’s mass.

2.6

Dust Mass Correlation

The particle size analyser/dust monitor determines the dust-concentration (counts/litre) through the

optical-light-scattering method directly; however, the mass concentration is determined by extrapolation.

The calculated mass concentration may be corrected to the specific aerosol measured with the

gravimetric-correction factor (C-Factor). Since the entire sample measured by the monitor is collected on

a filter, this value can be quickly determinate.

C Factor

Filter weight (loaded filter clean filter

Theoretical weight shown by the instrument

The "C-Factor" results from the equation: Theoretical mass / real filter weight

The ”C-Factor” is therefore mainly dependent on the aerosol density, refractive index and the form of the

aerosol collected. Each instrument is factory calibrated for size and mass as described in section 3.4.1

and leaves the factory with a C-Factor = 1.0

Notice:

All ENVIRONcheck are factory calibrated to ambient conditions and any

correlation check is ONLY recommended when a different aerosol is used.

Please note that this quick post correction is by far the simplest way to verify the instrument

in the field. For this validation of the filter it needs sufficient dust mass to be weighted, we recommend therefore to exchange this filter only on a monthly base.

The picture at the right shows the EPA approved 47 mm PTFE filter (2) for the dust collection and

analysis in the open filter holder (1).This is a view at the 107 bottom.

11

Please note that this quick post correction is by far the simplest way to verify the instrument in the field.

For this validation of the filter it needs sufficient dust mass to be weighted, we recommend therefore to

exchange this filter only monthly.

The picture at the right shows the EPA approved 47 mm PTFE filter (2) for the dust collection and

analysis in the open filter holder (1).This is a view at the 107 bottom.

3 SYYSSTTEEM

M OP

PE

ER

RA

ATTIIO

ON

N

3.1

System Components

The ENVIRONcheck system consists of the following items:

Real time Dust Monitor #107 and the

Humidity and temperature sensors embedded into the

165

Weather housing system with the

170M Sampling system

Since the 107 monitoring unit is also a fully independent portable dust monitor, it therefore could be used

as a stand alone unit.

3.2

The Dust-Monitor Model 107

This is a small portable unit, used for the continuous measurement of particles in the air (aerosols) and

their size distribution. The measurements are expressed in mass concentrations (in units of µg/m 3) , but

can also present the particle-concentration in counts/litre. All 107 units use the principle of orthogonal

light-scattering of the single particle , where a semiconductor-laser serves as light-sources. The scattered

signal from the particles passing the laser beam is collected at approximately 90° by a mirror and

transferred to a recipient-diode. The signal of the diode is feed, after a corresponding reinforcement, in an

15 size-canal classifier. Hereby, a pulse height analyser classifies the signal to a counter in each channel.

These counts can be displayed and are also stored in the memo card and transferred to the RS 232 for

computer analysis.

The ambient air is sucked with via an internal, volume-controlled pump through the sample cell and

through a collecting filter. This filter samples all the dust and can therefore be used for gravimetric control.

The pump also generates the necessary sheath air, which is filtered and passes through the sheath air

regulator back into the optical chamber. In this way no dust contamination comes to the laser-optic. This

particle free air flow is also used for the reference-zero tests.

At the beginning of each measurement, the instruments start a self-test for about 1/2 minute. The actual

dust-measurement therefore begins after the LCD-display shows the first results (all 6 seconds). This

real-time dust-concentration measurement data are transferred each minute to the removable storagecard, if used. Also via the built-in RS-232- are the available to an external computer or printer. These data

are available in intervals of 6 seconds (fast-mode), or 60 seconds (normal mode) or only on request.

12

RM

1 07

D

F5

F1

D1

F4

F2

A2

V3

P

PV1

F3

2

B2 B3

V2

B1

A1

1

V1

13

3.2.1

Measurement Range

Model

Mass-Concentrations (µg/m 3) and size channels

107 unit

1.0 – 1.500 µg/m3 of PM-10 and PM-2.5 and PM-1

3.2.2

Data presentation

Possibilities on the Model 107 LCD-Display

PM-10

PM-2.5

PM-1

EPA convention

EPA convention

Proposed EPA convention

Optional:

Particle count distribution as following:

ENVIRONcheck

Model 107

3.2.3

Sub-micron

0,3 – 0,4 – 0,5 – 0,65 -0,8 – 1,0 –

micron 1,6 – 2,0 - 3,0 – 4,0 – 5,0 – 7,5 – 10 – 15 - 20

Technical Data of 107

Measurement Principe:

90° light-scattering method.

Classification:

in different 15 channels.

All thresh holds:

are set for an efficiency of 50% with

monodisperse latex Aerosol.

Mass-calculation:

An additional canal becomes through

extrapolation below the finest measured canal.

Mass-calculation as arithmetic median value per

minute

Reproducible-performance:

±2% over the entire measurement range.

Self-diagnosis:

Automatically after each start.

Measurement time:

From 1 min until continuous.

Ample volume-stream:

1.2 l/min ±5% steadily through regulation.

Sheath air volume:

0.3 l/min steadily through regulation.

Filter sample-collection:

47 mm round-filters from PTFE (without

support).

Operation keys:

over foil-keyboard or RS-232 – Interface.

14

3.2.3.1

Data Presentation

LCD-Display:

2 x 16 signs.

Data shown on LCD-Display:

Dust-measurements as gliding median value

over a minute or mean values with total sampled

air, Alarm-values, Battery capacity, gravimetricfactor location NR., Date, time, measurements

data of the optional accessories.

Analog input:

3 ports (0-10V), resolution 10 bits, 0-10 mV

With165 weather housing

sensors for the temp. + rel. humidity

RS-232 Data-interface:

9600 Bit/s,8 bits, no parity,1 Stop-Bit, XON

/XOFF)

RS-232 Socket :

Only useful with original cable 1.143B!

3.2.3.2

Memory

Data-storage-card:

512KB to 6 MB on the card

Data collect:

measurement values each minute, date, time,

Location, C-. Error codes collected batterycapacity, motor-current, 3x analog-inputs.

3.2.3.3

Power Supply

Battery specification:

12V/2,0Ah, type LC-2PUAVBNC Panasonic,

fully loaded for 7 h of duration

18V-Power supply:

ASTEC SA45-3104, Input 100-240V AC,

Output max. 45W 18V DC

3.2.3.4

107 Monitor System Limits

Operational-temperature-range:

+4 to +40 °C, RH. <95% (not condensing).

Transportation-temperature-range: -20 to +50 °C, RH. <95% (not condensing).

Sampling air temperature:

-20 to +60 °C, RH <95% non-corrosive.

Pressure differential limits:

5 to –50 mbar (short-term)

(Maximum –100 mbar)

With overpressure:

max. +100 mbar with longer measurements

used.

Weather housing-temperaturerange:-20 to +40 °C, no limit for rH.

15

Housing of 107

green structured

24 x 12 x 6 cm

1.7 kg + battery (0.7 kg)

Housing-colour:

Dimensions:

Weight

3.2.3.5

Housing of weather housing

Grey glass fibre housing

40 x 40 x 30 cm

16 kg

Memory-functions

The function used in the last Standby-mode will boot up again. The display mode

remains as before; also the alarm-value, calculated filter-weight and sample flow remain

stored. Even when a power fail occurs during a measurement cycle all mean values

remain stored, so that with the power-return the measurement will automatically

continue.

Storage time for different data Logger Cards for a storage interval of 1 minute (values in

brackets are based on 60 minute data logging).

Storage

capacity

ENVIRONcheck

Model 107

If used in the

count mode

(opt.)

3.2.3.6

512KB

1024KB

6144KB

8d 16h

(1Y 155d)

2,9 Days

(173 Days)

17d 16h

(2Y 305d)

5,5 Days

(345Days)

34d 12h

(5Y 245d)

11,5 Days

(693 Days)

207d

(34Y 10d)

69 Days

(5520 Days)

Laser Power of 107:

Laser type:

Laser class:

107

3.3

256KB

Semi conductor-Laser diode

3B

675 nm

30 mW

0,65/20 mW CW (Multiplex)

Operational Mode of Monitor 107 (only)

The following chapter is an overview over the different service-elements of your dust-measuring

instrument.

Please READ the manual first,

than start up the dust monitor!

3.3.1

LCD-Display

The optical display on the unit consists of a LCD (Liquid-Crystal-Display) with all together 2 x 16,

therefore 32 characters. On this display are the measurement results of two channels, or date,

time, location (a two-digit number, that can be assigned to a certain area), battery power or Cfactor be shown. In addition, of course also all necessary error messages.

16

3.3.2

ON-/ OFF key

With the button ON/OFF, the instrument is started- as well as turned off. In order to interrupt not the

measurement inadvertently, the turn off becomes via software delayed for approximately 1 second.

Therefore the key must be pressed until the beep occurs. A renewed start should not be tried in less than

5 seconds.

Never TURN OFF the instrument in the run mode,

but first go in standby, than press the off key. Otherwise, it may lose data from the memory-card.

The unit interpret switching off during measurement as loss of power and it will, after the restart

boot up himself automatically. This means it will switch directly in the run mode without asking

for filter exchange and will calculate the mean values including the previous measurement.

If the instrument, for example through a strong outdoor disturbance and may reach an unidentified

condition, so that the software-keys to not react anymore, simply remove the battery and/or the power

supply. The instrument starts up normally and automatically again when putting in the battery or

connecting to the power supply. A measurement can therefore continue even after a power failure.

3.4

Key Functions

The key board on the Dust Monitor is shown below Each operation is confirmed by a short bleep. The

displayed mode is maintained as long as that key is pressed.

Between the standby and the run mode have some keys different functions, therefore read the following

two sections. Also notice that the instrument confirms each key pressing through a short beep.

17

3.4.1

Key Functions in the Operation Mode

Mean

Date/Time

Displays the mean value of the particle concentration of all measurements

after start of the instrument (and/or after the last resetting) with the

corresponding sample volume.

By pressing this key the current measurement and switches the instrument

into the standby mode.

Measured value output is stopped as long as the key is pressed. The

operating mode can be changed only during the standby mode!

Pressing the key shows the actual battery capacity in % and of the set

measurement point no. Please note that with an battery fully loaded, more

than 100 % AC, even 120 % can be displayed.

Press this key to call up the actual alarm value.

The cyclical display of the analogue input values are switched on by pressing

this key

The actual date and time are displayed by pressing this key

Status/C-Factor

Display any C-Factor selected. Should remain at Zero.

Standby

Size Mode

Battery / Location

Alarm

+

3.4.2

Key Functions in the Standby Mode

Mean

[Mean] & [-] key

[Mean] & [Status]

Standby

Size Mode

Size Mode

& [+] or [-] key

Battery/Location

[Battery/Location] &

[+] or [-] key

Alarm

[Alarm] & [+]

or [-] key

+

Date/Time

short pressing

Date/Time

longer pressing

Status/C-Factor

-

Display of the mean value of the particle concentration of all

measurements after starting the instrument (or after reset) with

corresponding sample volume

Reset of the mean value and of the mean value of measurement by

simultaneous pressing of the key

Formatting, testing and clearing of the memory

By pressing this key the standby mode will be left and a new series

of measurement will be started

Shows the display format of the PM- channels selected

Setting of the desired display format, such PM-10 or PM-2.5 or PM-1

Shows the actual battery capacity in %, and the set measuring point no

Changes measuring point no. Serves only to identify different

measurements and may be set between 1 and 99.

Call up of the actual alarm value

Changes alarm value. Zero deactivates alarm.

Display of mailbox and sheets upwards. After release of the key the

display is visible for approx. 3 sec.

Display of date and time

Setting of date and time. The number at which the flashing cursor is

found can by activated by [+] or changed by the [-] key.

By repeated pressing the date/time key the cursor keeps on being

switched. If you don’t press any key for a longer time there will be a

return into the standby mode. By change of minutes the seconds are

put on zero.

W permits entering by pressing [+] key a higher and by pressing [-] key

a lower value

Display of mailbox and sheets upwards. After release of the key the

display is visible for approx. 3 sec.

18

3.5

Print out from the Memory card

In the Standby mode you can, through the simultaneous pressing of the [Mean/Weight] and [alarm] key

transfer data of the logger card over the RS-232-port to a computer or an external printer. Only the data

obtained with the preset location-will be sent.

3.5.1

Data erasing on the data logger card

If you press the [Mean/Weight] and [Factor C] keys simultaneously, then, after confirming of the securityretrieval through pressing the [+]-key, all data on the data-storage-card each memory cell will be tested

and the memory will be formatted or erased. This is operation is only possible in the Standby mode.

3.6

3.6.1

System Interruptions

Error “No Function”

Please check connection to power supply into the 165 (Label: Power input 18V DC/2.5A) and connection

to second power supply (Mod. 1.112C) and wall socket.

3.6.2

Error „Mixer Error„ (Code 128)

Should the green LED light not shine, than you may have a basic functional problem witch will stop the

measurement completely. The possible problems are. Interrupted plastic pipe between the dust monitor

and the Air inlet to Mixer controller.

Check connection between temperature humidity sensor (1.153FH) and Dust Monitor.

Check connection between RS-232 cable from 165 (Label: to 1.100) and Dust Monitor.

The mixer valve is mechanically blocked

Problem with the mixer electronic

3.6.3

Error „New Calibration„ (Code 128)

This error only occurs in the start up and self test phase of the dust monitor. There are several possible

reasons, but the user can only clean the sample pipe with dry pressurized air. (For details see 4.4),

otherwise the unit has to be send to the nearest service station of Grimm.

3.6.4

Error „Check dust filter and air passage„ (Code 2)

This is only a warning message caused due to a very high motor current. A common reason for this is a

lot of dust on the filter or an appropriate filter been used. Since the sample air is maintained constant at

all times the obtained measurement values are still correct. Simply exchange the filter as outlined in 4.4,

this will protect the pump!

3.6.5

3.6.5 Error „Air pump problem current to high„ (Code 4)

The connection from the mixer to the sampling pipe in loose or badly connected. This message is caused

by a serious problem and will immediately stop the measurement. Most common there is an obstacle in

the sampling pipe or pump. (For details see 4.4) and if this does not resolve the problem the unit needs to

be send to the nearest service station

3.6.6

3.6.6 Error „Air flow not ok„ (Code 3)

This message occurs if the air flow can not be maintained constantly. This will stop the measurement.

Again .for details see 4.4.

19

3.6.7

3.6.7 Error „ no Memory card„ (Code 64)

There is no card or the memory card is not placed properly in the holder.

3.6.8

3.6.8 Error „ Please replace memory card-battery„ (Code 16)

Each memory card has an internal battery to buffer the data. If this message occurs the battery needs to

change.

Notice:

All errors are recorded on the memory card and can be seen at any time via the GRIMM

data analysis software

3.7

Start-up

Check please, as is described in whether the filter is properly put in the holder. If a gravimetric analysis

is desired it is necessary to determine the clean filter-weight.

Never operate the instrument without filters!

Because if the measured dust is N O T collected by the filter, it

it will enter into the pump and will destroy the dust monitor!

Remove the black protection cap over the air inlet before starting the instrument.

Connect the power supply or push a loaded battery into that intended compartment. Press the black

battery support knob when entering the battery in her compartment! The battery must vanish completely

in the compartment and through one click she is arrested. The instrument will boot up immediately and

independently. When the pressing the battery support know, the battery glides 3-5 mm out of her

compartment and can now be removed

Switch on of the dust monitor and verify if the LCD-display shows the model-name and the SoftwareVersion-number Approximately 15 sec. Later the unit shows the date and the time.

Model 107

Version 7.80

By pressing of the [Date-Time]-key the operating-hours of this instrument are displayed, when pressing

the [Mean]-key the specific serial number is shown. As operating-time the pump and laser-time operating

is calculated.

Inserted data logger Card: In this case the unit will identify the card, the version and show on the LCDdisplay, card size and version of storage card are shown, for example:

Card: 1024kByte

Version: 1.20

And subsequent the interval free remaining storage time (without overwriting of the data) is shown. The

storage time interval can be changed with the [+] and [-] key. The corresponding vacant storage time in

the 2nd line is updated at the respective interval.

20

Display for example:

Interval: 1 sec

free: 1d 15h 43min

The gravimetric-filter exchange will be the next question from the dust monitor to you . If you answer with

yes [+], the calculated filter weight as well as the affiliated sample air-volume will be set to zero.

Filter change

[+] no or [-]

In order to prevent an inadvertent erasure of the values delayed keyboard-retrieval follows, you must

press this key at least for one second, until the beep sounds. By pressing the [-} key, the instrument

continues adding the mass and volume data. Now, the instrument starts a self-test for approximately 30

seconds. If still you want to change some of the settings like alarm-value, time or the like to alter the size,

you need to press the [Standby] key, make your changes and than press the (standby key again for

start.) and the text below will occur:

Standby Mode

Press 2nd Key

Each measurement is started with a self-test, where the measurement-cell is purged with particle free air.

Several different internal measurements are enforced, from which conclusions about the status of the

instrument are made. If all tests pass, the message appears on the display “Calibration OK“ and

measurements will be shown, such as:

PM-10: 46 µg/m3

PM-2.5: 27 µg/m3

Alternatively the message: “New Self test” will appear. If this message should appear more than once, an

instrument failure is existing so, which must be remedied. Possible causes for this is are:

+ a lint, that hangs at the air-nozzle and sticks out into the laser-ray,

+ a very unclean measurement cell

+ an instrument-temperature over 50°C

+ a laser or another hardware-defect.

Try first to remedy the disturbance through a thorough cleaning of the air inlet. (See also Maintenance).

Alternatively, the instrument must be send to your nearest representative for service.

Now the dust-measurement begins and after each 6 seconds, results the results on the display are

updated. After the first minute, the measurement values will have stabilized themselves, (since the

gliding mean value of the last minute is established).

21

3.8

Factory calibration

As already described, each GRIMM dust-measurement instrument is calibrated in the factory and the

results obtained are supplied as test certificate with each instrument.

The control equipment and the obtained tolerance level is also shown. It will not exceed the 5% accuracy

level. After successful stearin-examination, a 3rd test is enforced with spherical glass-pearls with a density

of 2,8 and a refractive index of 1,36. The density-factor of 2,8 is put in solidly into the instrument.

3.9

Determination of the gravimetric-factor (C-Factor)

To do this a scale with the highest possible resolution is required. This means only a balance resolution of

10 µg should be used and at least 1 mg of dust should be collected on the filter to assure optimum

precision.

To obtain reliable results please follow step by step:

-

-

-

-

Take the old filter out of the filter-holder and clean the inner walls with a cotton

Wool-rod (for example).

Clean also the sample inlet as outlined under section.

Weigh a new filter (at least 3 times) and note the determined average-weight.

Put the new, weighed, filter in such a way in the filter holder that it covers completely

the small O-Ring. Don’t touch the filter with your fingers, than close the filter holder and tighten the

screw firmly.

Now switch on the dust-monitor and answer the question “filter changed” with yes [+],

so that the calculated filter-weight is reset to zero.

Make all your measurements at a the proper site. Please remember in case you interrupt the test

series to answer the filter-question “filter changed” always with no [-} The current calculated filterweight itself determinated by the dust monitor can be seen by pressing simultaneously the

[Mean/Weight] and the[+]-key – or over the RS-232-port to a PC.

After collecting sufficiently amount of dust on the filter, you can finish the measurement series, stop

by pressing [standby] and turn off the instrument.

Take out the filter, desiccate it and weigh this to the higher possible precision, at least again 3 times.

Now the difference to the clean-filter-weight is the collected dust mass.

Calculate the gravimetric-factor as outlined or enter the value into the software (optional) and the

computer will do it (in the extra mode). To improve the accuracy, you should verify this factor regularly

over time.

22

4 RS-232 INNTTEERRFFAACCEE AANNDD ANNAALLO

OG

GP

PO

OR

RTT

4.1

Concept of the RS-232-port

The serial interface consists of the 9-pin D-Sub socket at the instruments front and is marked “RS-232 “.

Via this interface, the dust-monitor can be controlled and the data can be transmitted to an external

printer or a PC. Over the interface-socket also the alarm-unit is supplied with power, it has a special

wiring of the pins. Therefore only with our original cable (NR. 1.143) it is possible to communicate with

the PC.

Pin-configuration at the dust-monitor:

Pin #2: RD (Data reception)

Pin #3: TD (Data transmission)

Pin #5: GND (Signal-ground)

Pin #7: Alarm 12V/0.5A (Tension for optional alarm-unit)

Pin #8: CTR (Start up contact)

4.2

Design of the Analog port

The dust-monitor has 3 analog connections (6 pin socket) on the right upper forefront, where the

matching analog sensor can be connected. The output signal is between 0 and 10 volts in each case.

This connection socket can also supply the external power for the +10 volts up to 40 mA .

Possible sensors, temperature -, air velocity -, air-pressure humidity, CO2, etc.... The measured analogue

values are stored on the data-storage-card and can be shown on the CLC display. The resolution

amounts to 10 bits (approximately 10mV). The texts and factors for the LCD-display can be changed.

Pins at the analogue socket:

1.

2.

3.

4.

5.

6.

4.2.1

Input 1

Input 2

Input 3

GND (mass)

+10V/40mA

free

Technical Sensor Specifications:

One of the possible sensors to be attached is the 1.153 temperature and humidity sensor, which has the

following specifications:

Dimension in mm:

Plug connection:

Power supply:

Temperature range:

Resolution:

Precision:

Humidity range:

Resolution:

Precision:

Air Velocity range:

Resolution:

Precision:

=15 mm, Length=200 mm, cable: ca.3m

6 contacts

10V ±5%, < 5 mA

0 to +80 °C

0.1 k

type. 0.3 k

0 - 100 % rH

0,1 %

type. 1 %

0,3 to 20 m/s

0,1 m/s

type. 1%

23

4.3

Communication Protocol Serial Com-Port

The Baud rate is 9.6 kBd for the normal data transfer. All signals are eight data bits without parity and one

stop bit are used. The software protocol XON/XOFF is supported. During the quick data transfer mode

the Baud rate can be up to 57.6 kBd.

During the ASCII data transfer to a printer also the CTS line can be called up by pressing the keys

[Mean/Weight] and [Alarm]. If there is no CTS line connected, the interface is considered to be vacant.

4.4

RS-232 Commands

Commands can be sent via the RS-232 interface to the Dust Monitor. The instrument will confirm the

reception of valid commands through an echo. At the commands capital or small letters are distinguished

commands. In many cases is the outgoing signalling reception a small letter, but if the reception of a

capital letter remains, an input is expected. Most of the capital letters (changes of settings) can only to be

sent in the Standby or Warm up mode.

The numeric values must be confirmed by pressing the enter key with a CR (carriage return). Any

changes that may be occur during the running measurement (for example ESC tension), the data output

is interrupted temporarily, but the data keep on being stored.

For test purposes you can use every terminal program which supports the XON/XOFF protocol. As

example the “TERMINAL” and “HYPERTERM” programs can be used which is anyway a part of the

accessories of Microsoft WINDOWS. The corresponding settings of the interface parameters however

must select before starting.

Remember that sometimes are the function keys of the program “TERMINAL” occupied with control

commands for possible other installed instruments, so check Configuration prior use.

A

B

C

D

E

Current alarm-value. He can be altered in the standby-mode.

Current battery-capacity

Count mode switched on / mass-concentration turned off

(only with Version from 5 and 6 )

ASCII-data-transfer of the data-storage-card (only in the standby)

Sends present error-code

Symbol of the respective error-code:

128: NEW CALIBRATION (fault zero)

64:

INSERT MEMOCARD also with Umc <2.8 VS

32:

CHECK NOZZLE Whirls> 5%

16:

NO OPERATION Battery empty = 0%

8:

PLEASE RECHARGE Battery <10%

4:

PUMP CURRENT TOO HIGH Imot> 100%

3:

FLOW-ERROR Pump-regulation outside of range

2:

CHECK FILTERS Imot <20%

1:

Imot> 60%

F

Almost-mode switches on. Results come all 6 seconds

G

Send gravimetric factor. This value can only be altered in the standby mode. The range

is between 0,1 to 9,9 with an incremental width of 0,05.

H

Total amount of operating hours

L

Location number of unit, can only be altered in standby-mode

M

Median value and air-volumes spend

N

Normal mode mass-representation (switches count mode off) only version. 5.0

24

O

Q

R

S

T

U

U=0

U=1

U=2

V

!

W

Z

@

^A

^B

^D

^E

^L

^V

_

$

$*

and 6.)

Send capacity of data-storage-card (only in the standby-mode). If a + is .

sent and the value, the data-storage-card will completely eliminated.

Quick-data-transfer of the data on storage card (only in standby-mode). If the datatransfer takes place in the binary-representation up to 57.6 Kbauds.

Run. Start of the measurements from the ”standby-mode “.

switches unit in ”Standby-mode”,

Time-edition. In ”standby” the clock can be changed.

Look the keyboard

Unlocks the keyboard

Can not shift to standby mode, mode is disabled.

keyboard-access not possible

shows version-number the dust monitor’s firmware

Shows model – and version-number of monitor

Shows filter-weight and sampled air-volume

(Zero-Edition. Sets the mean value and volume back to zero

Edition the serial number

Transmits calibration factor of the analog-sensors

Set of baud rate for quick-data-transfer

Interrupts the measurement-data transmission

Starts up the measurement-transfer / turns off of the fast-mode

Area/Country-date adjustment (E or U) (only in the standby-mode).

Changes software-version (only with appliance Mod. 1.105)

(ASCII 125) switches 5.x on the version, the sign {(ASCII 123) switches 4.x on

the version..

Example: [ASCII 22], [ASCII 125] switches 5 on version

[ASCII 22], [ASCII 123] switches 4 on version

Edition of the “User”-Text and entering analogue factors (only in standby-mode)

In the first line, the three “User”-selectable phrases are presented. In the second

line, the three multiplication-factors for the analogous-signals and the offset values

are shown.

The first line, the three “User”-selectable phrases are presented. In the second

line, the three multiplication-factors for the analogous-signals and the offset values

are shown.

Selection or change of the “User”-selectable phrases as well as factors for the analogue

signal to the LCD-display. (Only in the standby-mode).

Symbols (over ASCII 127) cannot be inputted.

With the edition, the sign becomes ‘ °’(ASCII 248) as ‘ _’ spent.

Pre-determined texts can be selected with the TAB

that through the enter key is confirmed. They can be headed also with any texts.

The number-edition is always in five digits and begins from the 9. Position. If signs

are entered, besides a decimal-point, an acoustic warning in generated. The

multiplication-factor, that is referential on 1V, can then after the text be inputted.

He can be changed through the command ` * ` alters.

Example:

Temperature-sensor 0°C:=:3.0V and 50°C:=:8.0V

User-Text:

Temp.: . °C

User-Factor: 10.0 [°C/V]

Offset:

- 3.00V

*: User-fractions alter. (Only in the willingness-mode)

25

The sequences of the data are as following:

Year Mon Day Hr min Loc GF Err Qbatt In the UeL Kal Ue3 Ue2 Ue1

Explanation:

Year – month – day – hour – minute – Location (1 - 99) – gravimetric-factor –error-code – battery-tension

– motor-current - zero-calibration - sensor 1 to 3 - interval .

The mixer operation is indicated with “ after the P = P”.

After the P values are the

“N” values for the mass concentrations PM-10, PM-2.5, PM-1.0 and than the

“C” values for the counts displayed (optional)

Therefore the ENVIRONcheck Model 107:

Accumulative size channels 1..15 (only in the Count mode)

Version : 7.80

Year Mon Day Hr

P 4 8 2 13 56

K. 2395 4021 4460

P 4 8 2 13 57

N_, 316 105 83

P 4 8 2 13 58

N_, 212 103 82

Min Loc GF Err Qbatt Im UeL Ue4 Ue3 Ue2 Ue1 Iv

13 0 64 130 8 85 1 0 0 0 0

5 0

13 100 0 130 31 149 1 0 0 0 0

13 100

0 130 31 149

1

0

0

0 0

In the Fast mode all 6 sec. The measured values will be transmitted

F

R

Year Mon Day Hr Min Loc GF Err Qbatt Im UeL Ue4 Ue3 Ue2 Ue1 Iv

P 4 8 2 14 7 13 0 64 130 8 149 1 0 0 0 0

Flow: 100 %

DC/v DC_d DC_h C0_h C0_d

K 2559 4207 4640 0 0

N0, 159 91 74

N1, 114 110 87

N2, 95 95 78

N3, 111 93 76

N4, 230 106 82

N5, 173 104 82

N6, 99 96 78

N7, 199 105 79

N8, 109 102 80

N9, 138 96 77

P 4 8 2 14 8 13 100 0 130 31 149 1 0 0 0 0

N0, 184 103 81

S

26

4.5

RS-232-Data transmission

In the RS232 data transmission (which can be seen over a terminal software) the mass values will be

shown in µg/m³ with a multiplication factor of 10. At the end of each measuring interval a row of internal

data will be displayed, followed by the mean of the mass values. “N” means mass value, “_” means mean

value and “,” stands for factor 10. To verify which data will be shown, enter the command “J”.

Version : 7.80

Year Mon Day Hr

P 4 8 2 13 56

K. 2395 4021 4460

P 4 8 2 13 57

N_, 316 105 83

P 4 8 2 13 58

N_, 212 103 82

Min Loc GF Err Qbatt Im UeL Ue4 Ue3 Ue2 Ue1 Iv

13 0 64 130 8 85 1 0 0 0 0

5 0

13 100 0 130 31 149 1 0 0 0 0

13 100

0 130 31 149

1

0

0

0 0

In the Fast mode all 6 sec. The measured values will be transmitted

F

R

Year Mon Day Hr Min Loc GF Err Qbatt Im UeL Ue4 Ue3 Ue2 Ue1 Iv

P 4 8 2 14 7 13 0 64 130 8 149 1 0 0 0 0

Flow: 100 %

DC/v DC_d DC_h C0_h C0_d

K 2559 4207 4640 0 0

N0, 159 91 74

N1, 114 110 87

N2, 95 95 78

N3, 111 93 76

N4, 230 106 82

N5, 173 104 82

N6, 99 96 78

N7, 199 105 79

N8, 109 102 80

N9, 138 96 77

P 4 8 2 14 8 13 100 0 130 31 149 1 0 0 0 0

N0, 184 103 81

S

The introduction-data in the line marked with “ P “ correspond to the bytes that are stored on the Memo

card. The resolution of the external tensions and the calibration value amounts to 10 bits, so that the

bytes, that are marked with Cal and Ue1 ..Ue3, represent only the higher quality part. The two lower-y bits

are transmitted in UeL . The bits 7 and 6 belong to Cal, the bits 1 and 0 to Ue1. Since the maximum-value

of these tensions amounts to 10 VS, the 10 bit-value must be multiplied with the factor 9.776E-3, in order

to come on the tension-value in volts. Because of unavoidable hardware-tolerances these values still

need to be corrected with an individual factor. The monitor can interrogate these factors. Since at the

monitor permits different “User” phrases and factors to be put in, this values will be given to the

appropriate software and are included into the calculations. The User-factors always refer to the tensionvalue in volts. The gravimetric-factor is multiplied with the factor 20, so that the resolution is 5% or better.

The battery-capacity and the motor-current are presented in percent. The sequence of the data are as

following:

Year Mon Day Hr Min Loc GF Err Qbatt Im UeL Kal Ue3 Ue2 Ue1 Iv

Explanation:

Year – month – day – hour – minute – Location (1 ..99) – gravimetric-factor –error-code – battery-voltage

– motor-current - sensor - zero-calibration - sensor 1 to 3 - interval .

The mixer operation is indicated with “ after the P = P”.

After the P values are the “N” values for the mass concentrations PM-10, PM-2.5, PM-1.0 and than the

“C” values for the counts displayed (optional)

27

ENVIRONcheck Model 107:

Accumulative size channels 1..15 (only in the Count mode)

Version : 8.10 for the ENVIRONcheck (Optional)

P ‘ 98 2 16 9 30

N_, 936 397 132

2 100 192 130 39 128

1

In the Fast mode are all the data in 6 sec. transmitted.

P 98 1 28 8 45 1 20 64 130 67 64 20 0

C0 88785 40485 6605

203

2

0

0

C1 95920 44045 7138

147

4

0

0

C2 103755 47615 7679

183

3

0

0

P

98 3

N0 56 56

N1 117 63

N2 74 61

4

38

37

33

17 1

1

51 55 52

50 115 112

56 73 70

20

44

105

63

0

0

0

0 0

0 0

0 0

0 0

0 0

64 130 56 64 21

24 11 0 0 0

90 69 63 63 63

47 34 23 23 0

0

0

0 0

5 GESYTEC INNSSTTRRUUCCTTIIO

ON

N FFO

OR

R ENVIRONC

CH

HE

EC

CK

K 107

(This is special network datalogger data transmission protocol mode)

Change of mode from STANDARD TO Gesytec-mode

The change from the STANDARD to the Gesytec-mode is only possible via the key board of the dust

monitor. Switch on the instrument and push the ON and „+“- key at the same time and keep both keys

pressed until on the LCD the model and firmware version are displayed. The instrument will directly

change over to the Gesytec-mode . This is shown on the display with an extra „S“ at the end of the

version.To return to the STANDARD mode switch off the dust monitor and start the instrument by

pressing the „ON“- and the „-“- key at the same time. Now the instrument returns to the selected mode, in

Europe as „E“ or in America as„US“ version.

5.1

Differences to the STANDARD mode

The only difference is an additional message in the RS232-string „:“ for the Gesytec- presetting. During

the Standby mode there is an extra signal as „:“ (ASCII-Code 58) transmitted, which will open a sub

menu as following:

Settings for the Gesytec

Instrument identification 123

Serial -number : 987

Baudrate RS232: 9600

[K] [S] [B] [Esc] [ENTER] ?_

28

After transmitting the „K“ is it possible to change the Instrument identification. Possible are the ranges

from 0 to 255.The Gesytec- Serial number can after transmitting the „S“ be set from 0 to 999.After

sending the signal „B“ will be the following helping text be shown. Now a number between 0 and 4 will be

expected:

Baud input : 0=1200 : 1=2400 : 2=4800 : 3=9600 : 4=19200

Baud rate RS232: 9600 ?_

By pressing the Escape key it is possible to exit from this submenu, without

changing the settings. By pressing the [ENTER] (ASCII-Code 13) key the changes are stored.

5.2

GESYTEC- Operation

5.2.1

Use directly from the instrument keys

The instrument can be operated independently from the reselected mode with two exemptions:

1. The Gesytec- Instrument recognition and the selected Baud rate can be seen by pressing the

„Size-Mode“- key in the standby mode.

2. The question if the filter has been exchanged remains only for ca. 3 Sec. Then it changes

automatically in the Standby mode.

5.2.2

Operating the unit via an external PC

This is the normal use of the protocol, since the instrument is installed in an environmental

monitoring network and transmits the results only when requested. (GESYTEC- Protocol)

All STANDARD mode operations can NOT be used when the dust monitor is switchedto this special

mode.

The signal comes as „ST“- Telegram.

The following „ST“- Telegrams are realised:

„R“ (Run)

„S“ (Standby) Stop of measurement

„N“ (Null) ( acts like in Run)

The „ST“- Telegram can be selected as ASCII- or Hex- instruction and is in the following ASCCIFormat:

FieldNr.

1

2

3

4

5

6

7

ByteNr.

1

2-3

4-6

7-8

9

10

11

Data

format

<STX>

ST

nnn

#A

<ETX>

<BCC1>

<BCC2>

Field description

Data

format

<STX>

ST

nnn

hh

<ETX>

Field description

Start of Text

Telegram code

Instrument code

Emty space key, ( mostly a letter)

End of Text

Block sign lower nibble

Block sign upper nibble

Hex-Format:

FieldNr.

1

2

3

4

5

ByteNr.

1

2-3

4-6

7-8

9

Start of Text

Telegram code

Instrument code

upper nibble, lower nibble

End of Text

29

6

7

10

11

<BCC1>

<BCC2>

Block sign of the upper nibble

Block sign of the lower nibble

The data obtained, which is only generated when the request „DA“ was issued, is identified as

„MD“- Telegram, in the following sequence and format:

FieldNr.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

ByteNr.

1

2-3

4-6

7-10

11-19

20-22

23-25

26-29

30-36

37-40

41-49

50-52

53-55

56-59

60-66

67-70

71-79

80-82

83-85

86-89

90-96

97

98

99

Data

format

<STX>

MD

03#

nnn#

±nnnn±ee#

hh#

hh#

nnn#

hhhhhh#

nnn#

±nnnn±ee#

hh#

hh#

nnn#

hhhhhh#

nnn#

±nnnn±ee#

hh#

hh#

nnn#

hhhhhh#

<ETX>

<BCC1>

<BCC2>

Field description

Start of Text

Telegram code

Amount of measuring places

Instrument identification

Value of PM10

Operational status

Error status

Serial number

Temperature in 1/10°C (F= Minus)

Instrument identification + 1

Value of PM2.5

Operational status

Error message

Serial number

relative Humidity in 1/10%

Instrument identification + 2

Value of PM1

Operational status

Erros status

Serial number

Motor current in %

End of Text

Block symbol lower nibble

Block symbol upper nibble

The „DA“- Telegram must contain the following format :

FieldNr.

1

2

3

4

5

ByteNr.

1

2-3

4

5

6

Data

format

<STX>

DA

<ETX>

<BCC1>

<BCC2>

Field description

Start of Text

Telegram code

End of Text

Block sign of the lower nibble

Block sign of the upper nibble

The sign „#“ symbols the space key , „nnn“ the numbers, „ee“ s the Exponent and „hh“ is the

hexadecimal presentation of one Byte.

The block diagram is composed by adding bytes over all transmitted symbols (incl. STX and EXT) and

the Exclusive - Or-Sum ( starting from Zero) . The result is shown as two nibble hexadecimal signal

and transmitted.

30

The error status is presented as Error-Code from the dust monitor. The Bit 1 in the operational-status is

set as Byte, as long as the dust monitor is in the Standby- Mode. The Bit 2 is send during the self test

phase only.

6 MEEAASSUURREEM

ME

EN

NTT MO

OD

DE

E

6.1

Determination of the “LOCAL” Density Correction factor

The dust monitor analyses the individual scattering signals, however the signal amplitude is not only a

matter of size and concentration, but also of the material and the particle shape, therefore a factor for the

correction of the results has to be determinated. The classical method, (as outlined in the manual 107

under point 4), by using the build-in dust sampling filter is not proper for environmental dust monitoring,

since the dust collection period is too long under the normal concentration exposures

We therefore recommend to operate the ENVIRONcheck system for min of 2 days in parallel with a high

volume sampler with a PM-10 or. PM-2.5 sampling head.. This helps to establish a quick and accurate

density correction factor Make sure booth systems have the sampling level at the same height and are

closed together.

Manual Method for a daily Mean value determination

The following steps should be done day after day:

a) Open the weather housing door

b) Stop the dust monitor by pressing the Standby key Prepare a new filter by properly weighing the

47 mm filter for the 107 dust monitor

c) Stop the high volume sampler and protocol all Hi-Vol. values

d) Read the mean value from the Grimm dust monitor.107 by pressing the „Mean/Weight„-key for 5

sec are longer. Record the underlined PM-mean value and the sampled air volume (You may

repeat this procedure if you like)

e) The 3rd PM-mean value can be read by pressing the „Size-Mode„-key and the „+„ or

„-key”. This will change the display mode. Now you need to repeat the step “f”

f) To rest the daily mean value press the key „Mean-Weight “until the sample volume is displayed

and than press additionally the Minus-key. The order will be confirmed by an acoustical signal.

This operation is done in the Standby-Mode or in the start-up mode Now you may take the filter

outlined in point a.) and place it into the 107 dust monitor

h) An alternative to h.) is to switch off and than start the instrument again. When the question

appears “Do you want to change the filter” simply press the Plus-key.

i) Booth systems should start at the same time again.

Attention!

Do not jet close the door of the weather housing, wait until the SELF-TEST of the dust monitor 107 is

completed. If all is working automatically you may than close the front door properly. (first the lower look

and than the security key above)

31

7 OUUTTDDO

OO

OR

R HO

OU

US

SIIN

NG

G MO

OD

DE

ELL 165

7.1

General information

For outdoor measurement the #107 dust monitor has to be protected against climate changes and harsh

condtions.

The dust monitoring system ENVIRONcheck of Grimm Aerosol Technik works in such a way that the

portable 107 monitor will fit perfectly into the outdoor housing and all connections and the logic will work

together.

The housing itself is absolutely water tight, so rain and other spill can not penetrate the monitoring

system. Therefore this unit is ideal for a stand-alone installation as road-side monitor, etc... Since is

maintains his internal temperature closed to 22 °C at all times.

High humidity can cause an error in the dust monitor readings because water molecules and nuclear

condensation with can misread as solid particles. In such a case the measurement requires a specialty

humidifier and this has been done here by using a special dehumidification system build into the weather

housing which does not haet or change the sample. Control of the humidity in the model ENVIRONcheck

Model #107 is the done with the humidity sensor because the air volume is constant 1.2 liter per minutes

and the delusion system which clicks in is in a ration of 1:1 so consequently the counter in the system is

counting half and automatically the actor will be multiplied because of the delution factor 1:1. The air then

goes into the mixing chamber in the air inlet pipe and to the dust monitor.

7.2

How to unpack and check for possible damage during transport.

Unpack the system and than open the door of the weather housing.

Attention! Only open if the housing is vertical, otherwise you may damage the door. Unlock first the

upper lock with the supplied key than open the lower look with the black general key. (Opens counter

clock wise)

Unpack system component s such as Power supply, Humidity and temperature sensor and Sensor

protection housing.

Remove transport protection from the dryer cartridge and protection caps from the connectors as well

as the protection cover on the 107 air and analogue inputs.

Control all components if they are complete. The system consist of the following: #Weather housing

165

- Security looking key for the housing

- Special chrome key for the front door

- Special tool key for the PG21-connection (air inlet pipe holder for 170M)

- Drying cartridge filled with blue Silicagel and two connecting screws

- Sensor protection housing for 1.153FH

- Power supply for 18V/2.5A DC

- Dust monitor model l07

- Connecting tube between dust monitor and air inlet to mixer controller

- Climatic sensor , incl. Calibration certificate 1.153FH

32

- Mini TSP-sampling head with internal heater connection 170M

- Drawing and installation instruction of the complete system

7.3

Operating instruction of the 107

Should the dust monitor not be connected via RS 232 to the weather housing, the unit functions like a

portable dust monitor fully independently.

7.4

The Humidity and Temperature Sensor

7.4.1

Humidity setting

If however the 107 is connected to the housing, the complete electronic of the housing is activated and

the mixer technology in operation. Now the humidity level can be seen by pressing the (ALRAM) key and

changed by pressing the + or - key as well. If the value. 0% is selected, the mixer works at all times,

otherwise only if the reselected % rel. humidity exceeds the set value. Please notice that there is a 5%

hysteresis in the humidity sensor possible, but this does not influence the efficiency of the system. We

recommend pre-setting the value at 80 % relative Humidity. (This can only be done in the standby mode)

Any possible error is shown on the LCD display as error-Code 128 and also an acoustical warning is

given and the instrument will stop automatically. It is now necessary to manually press the key StandbyMode to bring the instrument back into operation.

7.4.2

Installation of the Humidity /Temperature Sensor

a) Loosen the left PG21-screw on top of the housing.

Attention! Do not remove the lower inner part of the screw, this may be a possibility

for rain and water to enter into the housing.

b) Remove the stainless steel plate at the bottom.

c) Loose and remove the two black plastic screws for the dryer cartridge.

d) Pull out the dryer cartridge from the housing

e) Enter the temperature-/ humidity sensor from the inside in the sensor protection housing all the

way up to the top.

f) Insert the sensor protection housing with the temperature-/ humidity sensor in the left PG21-srew

connection and tighten the nut incl. Sensor cable.

g) The last step is to reinstall the dryer cartridge. Push the cartridge over the two supports and look

the cartridge with the two black screws manually.

h) Close the stainless steel plate again.

33

7.4.3

Installation of the power and connection cables

a) First remove the 3 nuts M3.

b) Than remove the stainless steel plate at the bottom.

c) Now dip the housing to the back, than insert the power supply cable (and the PC cable with the

RS232 port to the outside) through this hole, so that the inner length is long enough for the

connectors.

d) Now close the opening by returning first the rubber sealing, than the round plate and finally rescrew the 3 nuts properly.

e) To assure proper installation of the system at any platform assure that

f) the housing is tightened with two screws at the bottom to an external platform (the screws are

not supplied)

Should you need to hang the unit on a wall, there are two holes in the back of the housing

foreseen)

7.5

Installation of the Dust Monitor 107 inside the housing 165

a) First verify if there is a filter (Mod. 1.113A PTFE Filter) in the gravimetric filter holder properly

inserted.

b) Enter the 107 unit with the sampling port to the right side in the housing in such a way, that the plastic

pipe at the bottom hangs through the hole at the bottom of the instrument platform.

c) Slide the plastic pipe with the twist connector over this connector.

d) Than connect the temperature / humidity sensor cable with the analogue input port

e) Than connect the power cable adapter with the input port and

f) Finally connect the RS 232 port on the dust monitor (To tighten this connection you need to slide the

slider inside the upper plug to the left)

7.6

Installation of the sampling pipe 170M

Loose the upper right PG 21- screws so that the sampling pipe can be entered from the top

Attention! Do not unscrew nut completely, since the lower screw support will open and maybe

later rain could enter).

Enter the sampling pipe in such a way that the tube for the mixer enters first all the way down to the inner

support. Enter the sample pipe into the sample port on the dust monitor all the way. Finally tighten the

support screw on top of the housing. Connect the “Mixer Air outlet” tube from 170M to 165 (right side).The

tube from the sampling pipe should run behind the sampling pipe into the plug at the inner side of the

weather housing and be connected to the quick connector.

34

7.7

Electrical Installation and Start-up Procedure

a)

b)

c)

d)

Connect the inner power cable with the appropriate port (Power Input 18 VDC/2,5A).

Supply 220/110 V to the system.

Check if the internal fan is operating (only above ca. 20 °C).

Press the ON key on the dust monitor 107, the unit mast start.(For more details see the

ENVIRONcheck manual)

e) By pressing the Alarm key the pre-selected humidity value will be shown (65% is factory installation)

However you may change this settings by pressing in addition the „+„- or „-„-key. This change is only

possible in the Standby-mode and proper electrical connection between the dust monitor and the

mixer electronic. Should there be an error the instrument will show the preset alarm value in µg/m³

only!

f) By simultaneous pressing of the „Size-Mode„ and „Date/Time„ key are the actual temperature and

humidity values shown at the LCD display. The appropriate calibration data of the temperature and

humidity sensors are stored in an internal

EEPROM at all times.

Attention! Those EEPROM-values are only accepted by the dust monitor if the user

data in the dust monitor are not changed manually. (Factor = 1.0 and Offset =0.0)

g) Now answer the question from the dust monitor for filter change with YES or NO (For more details see

the manual ENVIRONcheck under 3.3.2) and the measurement mode will start. Only by pressing the

Stand-by-key this cycle will stop..

h) The dust monitor will firstly do his own SELF TEST. He will also read the temperature

and the humidity at the beginning of this first minute. He will also check the mixer

control. The green LED „mixer on„ must lighten up during this self test. This test

repeats himself after each start automatically. He should be observed to assure proper

mechanical connections. Only if all works to expectations you may close the front

door tightly. Should there be a mixer error the system will stop automatically and a

message of the error no. will appear (For more details see the manual ENVIRONcheck)

on the LCD display.

Attention!

For a proper function of the complete measurement system it is important that all

pneumatically components are tightened well. Also make sure the connections of the

mixer cartridge is tight.

35

i)

The red-colored LED “Housing Heater” must light up if the temperature inside the 165 under 20°C,

the fan stops and the housing heater starts now.

If at any time during measurement the „+„- key is pressed, you will see in regular intervals the

measurement values of the analog channels on the LCD- display. The start-up procedure is finished ,

if all is working to expectations

8 MAAIINNTTEENNAANNCCEE

8.1

General

The main routine service is around the weather housing. There is the regular exchange of the desiccant

material “Silicagel” necessary. The appropriate time can be found out by looking at the color of the color

of the Silicagel. At least once a month. If inside the mixer the Silicagel color gets “rose”, than it is time to

exchange the cartridge. Also the ventilation of the weather housing should be cleaned semi-annually. At

this time the air inlet filter should be exchanged.

The sampling pipe with the sampling head should be taken out of the weather housing and be cleaned

with compressed clean air.

8.2

Silicagel Exchange Procedure

The following method is recommended:

a)

b)

c)

d)

e)

Stop the dust monitor 107 by pressing the Standby-key. (In any case write down the mean values).

Pull off the power supply plug.

Open the stainless steal plate

Unscrew the two nuts holding the dryer cartridge.

Pull the cartridge forward until it is out of the housing and leave it in front of the housing

Attention:

f)

g)

h)

i)

j)

k)

l)

May case cancer by inhalation. Very toxic to aquatic organisms. May cause

long term adverse effects in the aquatic environment.

Open the cover screw on the lit

Take a large plate and dip the Silicagel into this plate.

Insert new Silicagel into the cartridge.

Clean the lit and than close the cartridge properly.

Push the cartridge back on the support rows, than re-screw the two nuts manually.

Disconnect the white tube between 165 and 170M. Start the Dust Monitor and if the pump inside of

the instrument get a high flow after approximate 1 Min. than you get a error message (“Air pump

problem current to high”), your system is pneumatic tight.

Now start the instrument again.

36

The used Silicagel can be dried in an oven at 120°C until it is blue again (Store the gel in a dry and

airtight bag).

8.3

ENVIRONcheck (Model 107) cleaning

The dust monitor is inside a metal housing for protection against mechanical and Electro- magnetically

influences. The key path and the LCD-window are to be protected against mechanical damage. Therefore

uses only a dry clean-ex or special computer cleaning tissues, do not use liquids to clean.

8.4

Sampling pipe and filter holder

After each time the filter is been taken out from the holder is recommended to clean the inner chamber

with a Q-Tip. Each ½ year the sample air should be clean as well. This is done by blowing clean air in the

sample inlet port (max. 3 bar) with the filter removed

8.5

Filter exchange

First switch off the dust monitor. Open the filter cover by turning the screw look a ¼ counter clock. Now

swing the cover downwards. By the use of an appropriate pincette take out the filter. Now clean the filter

holder as outlined above. Insert a new filter the same way you removed the used one. By during so do

not damage the O- ring inside the filter holder.

Close the cover and turn the screw ¼ clock wise until you feel a resistance. This would be a good time for

a gravimetric analysis.

Notice:

The lifetime of the pump get reduced with high dust load on the filter. Therefore exchange the filter regularly, we recommend to do so if the theoretical mass on the filter

reaches 20 mg or a warning signal is given by the dust monitor. In environ-mental

monitoring is this about every three months

37

9 DEELLIIVVEERRIIEESS, WAARRRRAANNTTYY AANNDD TRRAANNSSPPO

OR

RTTA

ATTIIO

ON

N

1. Your complete ENVIRONcheck system or just the Model 107 is delivered in a carton. Please ensure