In-situ SAXS-deformation studies on highly ordered block copolymers

advertisement

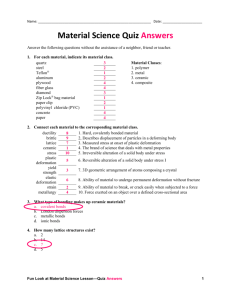

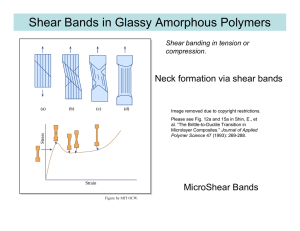

In-situ SAXS-Deformation Studies on Highly Ordered Lamellar Block Copolymers Yachin Cohen Department of Chemical Engineering, Technion , Haifa, Israel. Microphase-separated block copolymers exhibit interesting mechanical behavior due to their uniquely ordered morphologies. They find many useful applications, from the more conventional thermoplastic elastomers and toughened thermoplastics to more novel optical active devices. The mechanical response of a lamellar block copolymer structure, composed of alternating glassy/rubbery layers, is particularly unique: it exhibits a rigid elastic modulus at low strain followed by yielding and drawing to extremely high strain, with very high energy absorption. A reversible rubbery behavior is observed upon unloading and immediate re-stressing, Moreover, full recovery of the initial rigidity is achieved by annealing. The objective of this study is to elucidate the microstructural basis for the mechanical response of lamellar block copolymers by combining mechanical deformation with small-angle x-ray scattering (SAXS) measurements using the NSLS synchrotron facility. Electron and scanning probe microscopies were used to obtain complementary images of the morphologies. In this study polystyrene-polybutadienepolystyrene triblock copolymers were roll-cast to form globally oriented films with a lamellar morphology. In-situ deformation-SAXS experiments were conducted in three directions: perpendicular, parallel and diagonal (at 45 degrees) to the lamellar planes. In parallel deformation, macroscopic necking is due to break-up of the lamellar structure. The main deformation mechanism observed when stretching in the parallel and diagonal directions is formation of kink-grain boundaries oriented along the stretching direction. Symmetric kink boundaries, giving rise to the “chevron” morphology, are observed in parallel deformation, whereas diagonal deformation results in assymetric kink boundaries. With increasing strain the layers tilt in a manner which is affine with the macroscopic elongation, leading to rupture of the glassy layers at tilt boundaries. When the block copolymer structure is deformed above the glass transition temperature of the poly(styrene) layers, dilation of the layer spacing is observed, in an affine manner with the macroscopic elongation. At an intermediate temperature (80oC), layer dilation is observed at low strain, which transforms at the mechanical yield point to a combination of dilation with tilting of the layers at higher strains. An affine deformation model, accounting for these phenomena, is presented. (work done at: Dept. of Materials Sci. and Eng. MIT, with E.L. Thomas and R.J. Albalak)