Engineering Principals

advertisement

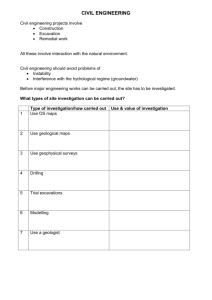

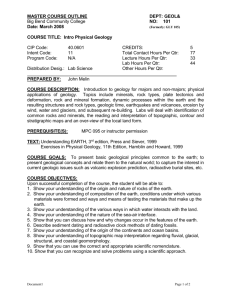

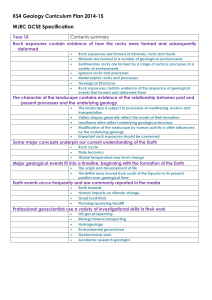

GL3 Engineering Geology Engineering Geology - Principles Geology and civil engineering Civil engineering projects can be small, such as constructing buildings and houses or very large, for example large dams. In all cases, geology has a major impact on the way in which these projects are undertaken and the term “geotechnics” is sometimes used to describe the geological techniques used in informing developers of the state of the ground they want to build on. The main purpose of the geotechnical surveys is to save the developer money in the long term by identifying potential problems and suggesting ways to overcome them. The way in which this is done is through a “site investigation”. Stages in the site investigation Initial stage: Desk study Site visit (“walkover survey”) Preliminary report and fieldwork plan. Main stage: Fieldwork o Geological mapping o Geophysical surveys o Trial pits, boreholes etc Laboratory testing Final report Review stage: Monitoring during excavation and construction You can see that the site geotechnical team has a lot of responsibility for insuring the success of the project. The Desk Study One of the most surprising things is that you don’t start drilling holes straight away. This is a very costly thing to do and probably the information you will obtain is available elsewhere. The engineering geologist will begin by studying records of the ground conditions from as many sources as possible. It is surprising just how many sources of information are available. These include the BGS, the National Geosciences Data Centre 1 GL3 Engineering Geology (borehole data), published material, local sources (local residents, experts etc), mining records, topographical maps, aerial photographs. The idea behind the desk study is that it is a cheap way of producing a lot of initial data about the site that can be used to “show the way” for the later stages. The walkover survey The engineering geologist next visits the site to identify obvious problems and causes for concern. From this an initial report is produced with a plan for the more detailed surveys later. Geological mapping The next stage involves fieldwork in which the engineering geologists visits the site in order to map the principal geological features such as rock type, unconsolidated deposits, water courses etc. Geophysical surveys These provide some of the most useful data for the geotechnical team. There are several types of survey. 1. Ground penetrating radar Microwaves are transmitted into the ground by a device mounted on a trolley. These are reflected off rock structures and recorded at the surface. An onboard computer measures the distance travelled and a profile of the subsurface is created. 2. Electrical surveys. The resistance to an electrical current can be measured between electrodes fixed into the ground (or lowered down a borehole). This is particularly useful for identifying the presence of metallic ore deposits and the presence of ground water. 3. Seismic surveys This uses shockwaves produced by hammer blows or explosions which become reflected or refracted from geological boundaries. (a) Reflection seismology – used for deep surveys such as those used to identify oil and gas deposits. (b) Refraction seismology – used for shallow surveys such as site investigations. As the shockwaves pass down from the upper layer to the layer beneath, they speed up and eventually return to the surface to be recorded at geophones. 4. Magnetic surveys. Using a magnetometer an operator can measure minor changes in the magnetic field – these may be caused by buried debris or shafts from old mine workings for example. 2 GL3 Engineering Geology 5. Gravity surveys Minute changes in the gravitational field are recorded. A negative anomaly may indicate the presence of a cavity under the surface. Boreholes The use of boreholes is the only way to really tell what type of rock is present under the surface and what possible problems may occur, but boreholes are expensive. There are a number of ways in which they can be used. Some borehole methods extract a tube of rock called a core which can be analysed in the lab. Alternatively, rock chips may be used, these are carried back from the drill head to the surface in a fluid. Additionally, some borehole drilling equipment are fitted with devices to measure permeability, electrical resistivity and rock strength. Laboratory testing Samples of rock or soil removed from the site can be taken to the laboratory for testing. Tests include several standard tests for rock strength. What are we looking for? All of these procedures are involved with finding what is called “difficult ground” in other words parts of the site where the rocks or geological structures may cause problems during excavation or construction. Examples: Ground subsidence – e.g. limestone with solution cavities, clay, peat, chalk, salt, gypsum, mined areas. Soft ground – e.g. alluvium, recent sediments, artificial “made” ground. Cavities and shafts Rockhead relief – the shape of the bedrock beneath the superficial deposits, crucial for tunnels and foundations. Slope failure 3