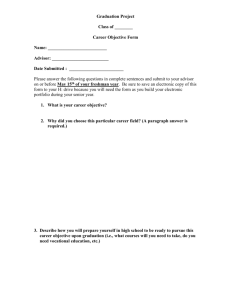

ISE 497-498 Senior Project Descriptions

advertisement

ISE 497-498 Senior Project Descriptions Systems analysis: Modeling and Optimization Students will gather data related to some factory (or plant), bank, or any economical system. These data may involve production, transportation, assignment, queuing or other operations research process in that system. After gathering data related to the system, students together with their advisor will determine a problem type. Students are required to develop a mathematical model for the problem identified, to solve it using GAMS software and analyze solution results. Advisor(s): Department staff Classification Algorithms in Data Mining and Applications Students will learn a mathematical programming based classification algorithm and are required to apply this algorithm to one of the following cases: in some clinic for determining the stages of the illness without making hard operations; in financial system for classifying customers in dependence on their credibility ratings, and so on. Students are required to write a GAMS code for solving the classification problem chosen, find an optimal solution and make a final decision. Advisor(s): Refail Kasimbeyli Portfolio Optimization Students will analyze different portfolio optimization models existing in the literature. These models will be applied to a selected number of companies from Istanbul Stock Exchange. By using the real life data for these companies, the project is required to make a decision on the optimal investment. The optimal investment will be found as a solution of the appropriate mathematical programming model by using GAMS software. Advisor(s): Refail Kasimbeyli, Selin Özpeynirci School Timetabling Students will analyze different school timetabling models existing in the literature. These models will be tried to be accommodated for applying to a real life data gathered from the Izmir University of Economics. The students are required to solve the corresponding mathematical model using GAMS software and compare results with the existing scheduling in the university. Advisor(s): Refail Kasimbeyli, Arslan Örnek 1 An Algorithm for Integrated Production Planning and Scheduling System Current production planning and scheduling approaches have lots of assumptions about production environment to make decisions easier. However, an optimal, at least better quality plans must consider the operational level of production. The objectives of this project are to develop a hierarchical algorithm that takes into account the tactical and operational levels of production planning and scheduling problems and build a lot sizing and scheduling model and solution methods that use dynamic lead times. Advisor(s): Arslan Örnek, Selin Özpeynirci, Cemalettin Öztürk Design and Scheduling of Flexible Mixed Model Assembly Lines Until now, assembly line design and scheduling problems have been considered separately in the literature due to different time frames of these problems. However, today’s competitive market conditions force decision makers to handle former tactical level design problems as operational. Hence, a combined approach that takes into account both aspects of this problem simultaneously is required. The objective of this project is to develop mathematical models and solution methods for simultaneously designing and scheduling of flexible mixed model assembly lines. Advisor(s): Arslan Örnek, Brahim Hnich, Cemalettin Öztürk Variants of Bus Scheduling Problems Both for achieving effective usage of public vehicles and increased citizen satisfaction, there is a need for optimized routing and scheduling of public service vehicles. Current studies about routing and scheduling of public service vehicles will be surveyed and an application oriented algorithm which considers more realistic cases will be presented. Advisor(s): Arslan Örnek, Cemalettin Öztürk Performance Evaluation and System Design with Simulation Modeling Simulation is a widely used technique in manufacturing and service firms to model and analysis their current work flow. Furthermore, it is a powerful tool for a system analyst to evaluate strong and weak aspects of processes. By using simulation modeling technique, alternative work plans and system designs could be tested without disturbing ongoing processes. 2 In this project, a simulation modeling study will be implemented in a manufacturing firm. Current work flow will be analyzed and required data for simulation database will be collected first. Then, alternative work designs will be developed. The last step of the project will be application of alternatives to the simulation model and reporting. Advisor(s): Cemalettin Öztürk Analysis and Design of a Manufacturing Firm Using Simulation Modeling Simulation modeling is powerful technique to analyze the current state of ongoing processes and developing alternative designs for better system performance. However, in the local firms, this technique is not known and used well. The objectives of this project are to analyze the current state of a manufacturing firm and model its processes by using ARENA simulation language, to detect weak aspects of the ongoing process by using simulation model and develop alternative redesigns using operations research techniques, to apply proposed redesigns by using simulation and report expected benefits. Advisor(s): Cemalettin Öztürk, Erdinç Öner Operation Assignment and Scheduling in Flexible Manufacturing Systems Flexible manufacturing systems are integrated systems of computer numerically controlled (CNC) machines and connected with automated material handling mechanisms. FMSs basically aim to maintain flexibility and effective utilization of the CNC machines through proper operation assignments and tool allocations. The objectives of this project are to develop a model to assign the operations and their required tools to CNC machines and determine the optimal schedule, and to build heuristic algorithms to solve large problems. Advisor(s): Selin Özpeynirci, Arslan Örnek Effective Allocation of Proposals to Panels One of the key problems for funding agencies is to determine the proposals that are worth funding through a peer review process. In this problem, there is a peer review system in which proposals are divided into panels and reviewed by a panel of experts. A key problem in this setting is to allocate proposals to a minimum number of panels under a certain set of constraints. Advisor(s): Selin Özpeynirci Improvement of the Izmir University of Economics (IEU) Webpage Design from a Human Factors Point of View. 3 The project requires extensive literature review on the human factors and ergonomics principles in webpage design and system design. Based on the literature and IEU webpage user characteristics the current webpage design and usability will be evaluated and better design will be recommended based on the human factors principles. Advisor(s): Erdinç Öner Analysis of Working Conditions at a Selected Service or Production Industry. Establish current working conditions and environment from ergonomics point of view. Determine and propose procedures that would improve working conditions and improve workers satisfaction. Advisor(s): Erdinç Öner What can we do to decrease crash rates at traffic signals? The analysis of the crash rates at urban traffic signal locations and the analysis of the effect of the visibility of traffic signals in crash rates. a. Data collection on the crash rate statistics at urban traffic signals. b. Analysis of the literature and crash data to determine the effect of visibility problem in crashes. c. Literature review to determine the visibility requirements for traffic signals (traffic signal regulations in Turkey, US and Europe). d. Propose improved traffic signal designs from a human factors point of view that would improve visibility of the traffic signals and decrease the number of crashes in return. Advisor(s): Erdinç Öner Production Planning and Control for Poultry Production Advisor(s): Mahmut Ali Gökçe Load Determination and Vehicle Routing Problem for Freezer-Refrigerated Truck Fleet Advisor(s): Mahmut Ali Gökçe Multi Level Lot Sizing and Scheduling for Discrete Manufacturing Multilevel lot sizing and scheduling is both a very practically important and academically challenging problem. The main purpose is to determine lot sizes and scheduling of these lots for orders to satisfy demand for the parts of a product with a multilevel BOM (Bill of Materials), given the orders, due dates, product structure and machine compatibility and capacities. 4 Advisor(s): Mahmut Ali Gökçe Production Planning and Scheduling of Flexible Assembly System in Apparel Production Advisor(s): Mahmut Ali Gökçe Hybrid Optimization Methods for discrete Manufacturing Combining exact optimization methods (like Mathematical Programming, Lagrangean Methods etc.) With heuristic approaches to solve real life size problems quickly. Advisor(s): Mahmut Ali Gökçe Advanced Planning and Scheduling in MRP Systems How to determine machine/workcenter loads and schedule them in a MRP system Advisor(s): Mahmut Ali Gökçe 5