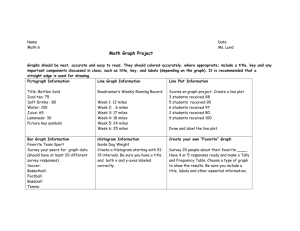

MILESv1.0_update

advertisement

Page : 1/108

February 15, 2006

COSTING STUDY

FOR

MILES

(MultI-object Laser-Enhanced Spectroscopy)

A new concept for wide-field UV/optical spectroscopy

for the TMT project.

Keith Taylor, Anna Moore,

Rich Dekany, Matthew Britton

(Caltech)

Chris Clemens

(UNC)

&

Damien Jones

(Prime Optics, Qld, Australia)

February 2006

Page : 2/108

February 15, 2006

TABLE OF CONTENTS

Page

1.

EXECUTIVE SUMMARY

8

1.1

Acronyms and Abbreviations ............................................................................................................. 9

1.2

List of Symbols and Units ................................................................................................................ 10

2.

THE MILES CONCEPT

11

2.1

Introduction ...................................................................................................................................... 11

2.1.1

Compliance with the Science Requirements: ............................................................................. 11

2.1.2

Telescope compatibility ............................................................................................................... 12

2.2

Concept overview ............................................................................................................................ 12

2.3

The 3MfR Focal Reducer................................................................................................................. 15

2.3.1

Optical Performance.................................................................................................................... 15

2.3.2

3MfR Reflection Losses .............................................................................................................. 15

2.3.3

The GLAO Capability .................................................................................................................. 15

2.3.4

Multi-slit assembly ....................................................................................................................... 17

2.3.5

Other benefits of the active GLAO mirror.................................................................................... 17

2.3.6

3MfR Baffling ............................................................................................................................... 17

2.3.7

Calibration Sources ..................................................................................................................... 18

2.3.8

3MfR Output Focal Surface:........................................................................................................ 18

2.4

The spectrograph ............................................................................................................................. 18

2.4.1

Collimator..................................................................................................................................... 18

2.4.2

Dispersive Elements.................................................................................................................... 18

2.4.3

Camera ........................................................................................................................................ 20

2.5

The atmospheric Dispersion Corrector (ADC) ................................................................................ 21

2.6

Throughput ....................................................................................................................................... 22

2.7

Instrument Layout, Size and Weight:............................................................................................... 23

2.7.1

Weight/Space budget .................................................................................................................. 25

2.8

Conclusions:..................................................................................................................................... 26

3.

RESPONSE TO REVIEW PANEL (APRIL, 2005)

27

3.1

Curved CCDs ................................................................................................................................... 27

3.2

Availability of Large CaF2................................................................................................................. 27

3.3

PSF Variability of SLGLAO .............................................................................................................. 27

3.3.1

Introduction .................................................................................................................................. 27

3.3.2

SLGLAO Results ......................................................................................................................... 28

3.3.3

Architecture Comments ............................................................................................................... 31

4.

SUB-SYSTEM ANALYSIS

33

4.1

Atmospheric Dsipersion Compensators .......................................................................................... 33

4.1.1

Function ....................................................................................................................................... 33

4.1.2

Specifications .............................................................................................................................. 33

4.1.3

Interfaces ..................................................................................................................................... 33

4.1.4

Description ................................................................................................................................... 33

4.1.4.1

Opto-mechanical requirements

37

4.1.4.2

Mechanical overview

38

4.1.5

Performance and Compliance .................................................................................................... 41

4.1.6

Development Risks ..................................................................................................................... 41

4.1.7

Cost and FTE .............................................................................................................................. 42

4.2

3MfR Focal Reducer ........................................................................................................................ 42

4.2.1

Function ....................................................................................................................................... 42

Page : 3/108

February 15, 2006

4.2.2

Specifications .............................................................................................................................. 42

4.2.3

Interfaces ..................................................................................................................................... 42

4.2.4

Description ................................................................................................................................... 43

4.2.4.1

Mechanical support

43

4.2.5

Performance and Compliance .................................................................................................... 45

4.2.6

Development Risks ..................................................................................................................... 47

4.2.7

Cost and FTE .............................................................................................................................. 47

4.3

Slit Mask Units ................................................................................................................................. 47

4.3.1

Function ....................................................................................................................................... 47

4.3.2

Specifications .............................................................................................................................. 47

4.3.3

Interfaces ..................................................................................................................................... 48

4.3.4

Description ................................................................................................................................... 48

4.3.5

Performance and Compliance .................................................................................................... 48

4.3.6

Development Risks ..................................................................................................................... 48

4.3.7

Cost and FTE .............................................................................................................................. 48

4.4

Collimators ....................................................................................................................................... 49

4.4.1

Function ....................................................................................................................................... 49

4.4.2

Specifications .............................................................................................................................. 49

4.4.3

Interfaces ..................................................................................................................................... 49

4.4.4

Description ................................................................................................................................... 49

4.4.5

Performance and Compliance .................................................................................................... 49

4.4.6

Development Risks ..................................................................................................................... 49

4.4.7

Cost and FTE .............................................................................................................................. 49

4.5

VPH Gratings ................................................................................................................................... 50

4.5.1

Function ....................................................................................................................................... 50

4.5.2

Specifications .............................................................................................................................. 50

4.5.3

Interfaces ..................................................................................................................................... 51

4.5.4

Description ................................................................................................................................... 51

4.5.5

Performance and Compliance .................................................................................................... 51

4.5.6

Development Risks ..................................................................................................................... 51

4.5.7

Cost and FTE .............................................................................................................................. 51

4.6

VPH Exchange Mechanism ............................................................................................................. 51

4.6.1

Function ....................................................................................................................................... 51

4.6.2

Specifications .............................................................................................................................. 52

4.6.3

Interfaces ..................................................................................................................................... 52

4.6.4

Description ................................................................................................................................... 52

4.6.5

Performance and Compliance .................................................................................................... 52

4.6.6

Development Risks ..................................................................................................................... 52

4.6.7

Cost and FTE .............................................................................................................................. 52

4.7

Camera Articulation Mechanisms .................................................................................................... 52

4.7.1

Function ....................................................................................................................................... 52

4.7.2

Specifications .............................................................................................................................. 53

4.7.3

Interfaces ..................................................................................................................................... 53

4.7.4

Description ................................................................................................................................... 53

4.7.5

Performance and Compliance .................................................................................................... 54

4.7.6

Development Risks ..................................................................................................................... 54

4.7.7

Cost and FTE .............................................................................................................................. 54

4.8

Cameras........................................................................................................................................... 55

4.8.1

Function ....................................................................................................................................... 55

4.8.2

Specifications .............................................................................................................................. 55

4.8.3

Interfaces ..................................................................................................................................... 55

4.8.4

Description ................................................................................................................................... 55

4.8.5

Performance and Compliance .................................................................................................... 56

Page : 4/108

February 15, 2006

4.8.6

Development Risks ..................................................................................................................... 57

4.8.7

Cost and FTE .............................................................................................................................. 57

4.9

Detectors .......................................................................................................................................... 57

4.9.1

Function ....................................................................................................................................... 57

4.9.2

Specifications .............................................................................................................................. 57

4.9.3

Interfaces ..................................................................................................................................... 58

4.9.4

Description ................................................................................................................................... 58

4.9.5

Performance and Compliance .................................................................................................... 58

4.9.6

Development Risks ..................................................................................................................... 58

4.9.7

Cost and FTE .............................................................................................................................. 58

4.10

Support Structures ........................................................................................................................... 59

4.10.1

Function .................................................................................................................................. 59

4.10.2

Specifications .......................................................................................................................... 59

4.10.3

Interfaces ................................................................................................................................ 60

4.10.4

Description .............................................................................................................................. 60

4.10.5

Performance and Compliance ................................................................................................ 60

4.10.6

Development Risks ................................................................................................................. 60

4.10.7

Cost and FTE .......................................................................................................................... 60

5.

SCHEDULE AND BUDGET

61

5.1

Summary .......................................................................................................................................... 61

5.2

Product Breakdown Structure (PBS) ............................................................................................... 62

5.3

Work Breakdown Structure (WBS) .................................................................................................. 64

5.3.1

Summary WBS ............................................................................................................................ 64

5.3.2

Detailed Work Breakdown Structure (WBS) ............................................................................... 65

5.4

Project Schedule .............................................................................................................................. 70

5.4.1

Critical Path ................................................................................................................................. 70

5.4.2

Gantt Chart .................................................................................................................................. 70

5.5

Cost Estimate ................................................................................................................................... 73

6.

WFOS-PETITE: A SINGLE-BARREL VERSION OF MILES

75

6.1

Introduction ...................................................................................................................................... 75

6.2

The D4 Advantage ............................................................................................................................ 75

6.3

Seeing-Limited Science on TMT: .................................................................................................... 79

6.4

Conclusions...................................................................................................................................... 79

7.

REFERENCES

83

8.

APPENDIX I (VPH GRATINGS)

84

8.1

VPH gratings in the context of 30 meter telescopes ....................................................................... 84

8.2

The importance of the maximum working angle ............................................................................. 85

8.3

Assessment of the MILES concept ................................................................................................. 89

8.4

Possible changes to the MILES concept design ............................................................................. 95

8.5

Conclusions...................................................................................................................................... 96

9.

APPENDIX II (OPTICS PRINCIPLES)

98

9.1

Preamble .......................................................................................................................................... 98

9.2

Optical Principles ............................................................................................................................. 98

9.2.1

Telescope .................................................................................................................................... 98

9.2.2

Focal Reducer ............................................................................................................................. 98

9.2.3

Collimator................................................................................................................................... 101

9.2.4

Camera ...................................................................................................................................... 102

9.3

Optical Prescription ........................................................................................................................ 102

Page : 5/108

February 15, 2006

9.4

9.5

Optical Performance ...................................................................................................................... 102

Remarks ......................................................................................................................................... 102

10.

APPENDIX III (COMPETITVE QUOTES)

104

10.1

Preamble ........................................................................................................................................ 104

10.2

The Quotes .................................................................................................................................... 105

10.2.1

Tinsley (Quotation no. 2069) ................................................................................................ 105

10.2.2

Saint-Gobain Crystals ........................................................................................................... 105

10.2.3

Goodrich-Danbury ................................................................................................................ 106

10.2.4

SAGEM DS ........................................................................................................................... 106

10.2.5

SAGEM Défense Sécurité .................................................................................................... 106

10.2.6

LightWorks Optics ................................................................................................................. 107

10.3

Remarks ......................................................................................................................................... 107

Page : 6/108

February 15, 2006

TABLE OF FIGURES

Figure 2:1 4-barrel layout on f/15 (or f/22) focal plane. .................................................................................... 14

Figure 2:2 Isometric view of f/15 system (as seen from the telescope) ............................................................ 14

Figure 2:3: 3000 l/mm grating necessary to achieve highest resolutions at the UV/blue end of the instrument

bandpass. The curves represent the efficiencies at working angles 33°- 45° (from left to right) in

increments of 3° degrees. The CCD coverage (not shown) is about 50nm at this dispersion. This

grating is 5m thick with a 0.035 variation in the refractive index. ............................................................ 19

Figure 2:4: Efficiency curves for blue blazed and red blazed 1200 l/mm gratings. The blue lines are angles

of 10° -25° for a 5m grating with 0.05 index modulation. The red lines are angles 25° - 40° degrees for

a 5m grating with 0.1 index modulation. .................................................................................................. 20

Figure 2:5 Spot plots for an f/15 3MfR system with uncompensated ADC at maximum extension (circles are

1” dia). ........................................................................................................................................................ 21

Figure 2:6 Spot plots for an f/15 3MfR system with a GLAO-mirror compensated ADC at maximum extension

(circles are again 1” dia)............................................................................................................................. 22

Figure 2:7 Side view........................................................................................................................................... 24

Figure 2:8 Rear View (towards telescope). ....................................................................................................... 25

Figure 3:1 Radial cuts through the diffraction limited, seeing limited and SLGLAO PSFs for the three

turbulence profiles in Table 3:1 and observing wavelengths of 1.3μm and 0.8μm. The SLGLAO PSFs

are shown for angular offsets of 0, 30 and 60”from the laser guide star. ................................................. 30

Figure 3:2 Optimal slit widths and integration time improvements as a function of observing wavelength for a

SLGLAO architecture for the good and typical turbulence profiles in Table 3:1. Curves are shown for

angular offsets of 0”, 60”, and 120” from the laser guide star. .................................................................. 31

Figure 4:1: The optical design of the MILES trombone ADC, shown for top and bottom fields. Three field

angles are shown for one wavelength only. .............................................................................................. 34

Figure 4:2: The ADC units shown configured for a minimum zenith angle of 0o, hence minimum dispersion is

introduced by the prisms. ........................................................................................................................... 35

Figure 4:3: An overview of the MILES trombone ADC. For each of the 4 optical channels there is one

trombone ADC composed of 2 large fused silica prisms, ADC1 and ADC2. ADC1 is moved relative to a

stationary ADC2 as a function of telescope zenith angle, the larger the zenith angle the larger the

separation. The prisms differ slightly in thickness, as discussed in the text. ........................................... 36

Figure 4:4: The 4 channels of the MILES trombone ADC.................................................................................. 38

Figure 4:5: Overview of the ADC1 mechanical assembly. Each prism has 4 degrees of freedom:, 3

translational and 1 rotational. All 4 ADC1 cells onto 1 plate (colored green) so that the z-axis translation

can be performed using one mechanism for all optics. Similarly for the y-axis movement the top and

bottom pairs are mounted onto a y-stage. Movement along the x-axis is unique to each prism cell and

therefore each prism has a separate x-stage. The rotation mechanism, a rotational friction drive is

directly mounted to the x-stage together with the roller bearings that support the prisim cell and allow

rotational movement. ................................................................................................................................. 39

Figure 4:6: A close-up of the ADC1 prism assembly. ........................................................................................ 39

Figure 4:7: The MILES trombone ADC1 assembly in the instrument enclosures. ............................................ 40

Figure 4:8: A suitable friction drive for the z-axis motion of the ADC1 assembly. ............................................. 41

Figure 4:9 3MfR paraxial schematic. ................................................................................................................. 43

Figure 4:10: The 1.6m diameter paraboloid of the Infrared Spatial Interferometer Array (ISI, UC Berkeley)

adopts a simple radial chain support. The mirror is stationary with optical axis horizontal. ..................... 44

Figure 4:11: The optics and location of the 3MfR for one of the 4 MILES channels ........................................ 45

Figure 4:12 Spot plots for an f/15 A-G telescope (circles are 0.5” dia). ............................................................ 46

Figure 4:13 Spot plots for an f/15 to f/7.5 3MfR system (circles are again 0.5” dia). ........................................ 46

Figure 4:14 An example mechanical mask in development for various 8m telescope projects. ...................... 48

Figure 4:15 The 4 articulated cameras, excluding the frame-work surrounding them, are shown as mounted

on dual optical benches. The arrows indicate the direction of articulation with the underlying 2-fold

symmetry clearly demonstrated. The 90° circular guide rails are mounted directly onto the optical

benches beneath the primary mirror of each camera. .............................................................................. 54

Figure 4:16 Imaging spots for the full telescope/3MfR/spectrograph optical train. (Circles are 1.0” dia). ....... 56

Figure 4:17 Example spectroscopic spots (R0.75 ~4000) assuming a centered slit (c ~350nm) out to the

edges and corners of the detector. (Circles are again 1.0” dia). .............................................................. 57

Figure 4:18: Schematic of the MILES support structure. The enclosure is supported on a 3-point mount

comprising a self-aligning rotation bearing at the rear of the instrument and 2 roller bearings at the front

Page : 7/108

February 15, 2006

of the enclosure. A worm drive, located close to the plane of the roller bearings, provides the rotation

mechanism for the field de-rotation. .......................................................................................................... 59

Figure 5:1. Product Breakdown Structure for MILES. The costing was developed according to the underlying

structure of the physical units of the MILES instrument. ........................................................................... 62

Figure 5:2. MILES Gantt chart (part 1) ............................................................................................................... 71

Figure 5:3 MILES Gantt chart (part 2) ............................................................................................................... 72

Figure 6:1 In this plot the ordinate (or y-axis) defines C in terms of spatial resolution (in mas) for a range of

spectral resolving powers (R) for four photometric bands......................................................................... 78

Figure 6:2 As in Figure 1, the ordinate defines C in terms of spatial resolution (in mas) but now for a fixed

spectral resolution (R=4,000) for all wave-bands from U through K. The improvement in spatial

resolution (C) obtained in the case of under-sampled spectral information (eg: 1-pixel per spectroscopic

slit) is highlighted. ....................................................................................................................................... 78

Figure 6:3 A sketch of WFOS-petite showing one (red) ADC barrel of MILES, a 45° fold to the vertical axis,

the 3-mirror Offner relay, the dichroic LGS splitter and one (yellow) barrel of the MILES spectrograph

shown protruding below the Nasmyth platform. The bottom “box” represents the space for the camera

articulation; the whole of the (yellow) spectrograph, including this “box”, rotates on a vertical axis

underneath the stationary Offner relay, mitigating the otherwise serious flexure issues associated with a

horizontal mount......................................................................................................................................... 82

Figure 7:1: The drop in VPH efficiency maxima at large working angle due to polarization effects. Surface

reflection losses are not included. ............................................................................................................. 87

Figure 7:2: Efficiency curve for a 400 mm pupil WFOS at maximum working angle of 37 degrees (1800 l/mm

grating, blue line) and the same curve for a 300 mm pupil WFOS at a maximum working angle of 45

degrees (2120 l/mm grating, red line). The bars denote typical CCD coverage, which is the same in

each case because the camera f ratio was held constant. ....................................................................... 88

Figure 7:3: 3000 l/mm grating necessary to achieve highest resolutions at the UV/blue end of the instrument

bandpass. The curves represent the efficiencies at working angles 33-45 degrees (from left to right) in

increments of 3 degrees. The CCD coverage (not shown) is about 50 nm at this dispersion. This

grating is 5 microns thick with a 0.035 variation in the refractive index. ................................................... 90

Figure 7:4: 2400 l/mm grating shown at angles from 25 to 45 degrees (left-to-right) in 5 degree increments.

The vertical bars show the edge of the CCD for the 35 degree curve. The other curves have

comparable wavelength coverage. This grating is 5 microns thick with 0.050 index variation. .............. 91

Figure 7:5: 1800 l/mm grating shown at angles from 25 to 45 degrees (left-to-right) in 5 degree increments.

The vertical bars show the edge of the CCD for the 35 degree curve. This grating is 5 microns thick with

0.085 index variation. ................................................................................................................................. 91

Figure 7:6: Efficiency curves for blue blazed and red blazed 1200 l/mm gratings. The blue lines are angles of

10-25 degrees for a 5 micron grating with 0.05 index modulation. The red lines are angles 25-40

degrees for a 5 micron grating with 0.1 index modulation......................................................................... 92

Figure 7:7: 600 l/mm blue grating at angles from 5-17 degrees in increments of 2 degrees. This grating is 9

microns with a modulation of 0.03. The greater thickness is necessary for efficientt scattering at low line

density in the blue. ..................................................................................................................................... 92

Figure 7:8:600 l/mm red grating at angles from 11-17 degrees in increments of 2 degrees. This grating is 5

microns with a modulation of 0.09. ............................................................................................................ 93

Figure 7:9: 350 l/mm grating that works efficiently over the entire instrumental bandpass. The angles shown

are 4, 6, 8, and 10 degrees, with CCD edges shown for the 6 degree case. This example also illustrates

how the efficiency drops for 2 degree field angle changes (equivalent to 1.7’ offset from center field) ,

and demonstrates that MILES will have good performance even for objects near the field edge. It also

shows that MILES will no require reflection gratings at low density. ......................................................... 94

Page : 8/108

February 15, 2006

1. EXECUTIVE SUMMARY

The Caltech Optical Observatories (COO) was contracted by the TMT Project to undertake a costing

study of their MILES concept that was developed to satisfy the requirements for a Wide-Field MultiObject UV/Optical spectrograph (WFOS). This costing study was in response to a proposal by COO, in

collaboration with Chris Clemens (UNC), to undertake a feasibility study. While the proposal was

rejected, nevertheless the basic idea was seen have sufficient merit to warrant a Costing Study which

would give the TMT Project a cost/performance base-line for assessing the various WFOS options under

consideration both now and in the future. The following is a little more than a costing study.

We begin, in Section 2, with a review of the MILES concept itself, taken largely from the original

proposal. This is followed by a brief examination (Section 3) of the RfP Review Panel’s comments on the

MILES concept, that were made available to the team. Section 4 presents a sub-system analysis of the

critical components of the instrument with a description of the functionality, specifications, interfaces and

description of each. Also included are material and labor cost estimates taken from the Product (PBS) and

Work Breakdown Structure (WBS) analysis of the program of work.

Section 5 presents the schedule and budget estimates as derived from a PBS and WBS analysis and

concludes with an overall budget (without formal contingency) of ~$53M with the project spanning the

next ~8 years.

Finally, in Section 6 we present arguments for de-scoping to a single-barrel version of MILES which we

refer to as WFOS-petite. Such an instrument, while having only a 1/4th of the field area of WFOS would

nevertheless be otherwise fully compliant with the SRD specifications. It would cost something less than

~$20M and, should the Caltech vision of IRMOS be chosen, could share TiPi’s Offner relay rather than

having its own dedicated relay (the 3MfR) thus presenting further savings to the Project in both funding

and infrastructure. Furthermore, as we will show, such a concept allows the instrument to bi-pass the 3mirror reflections of the Offner relay when AO-assisted observation are not required.

This, we argue, would be a cost-effective way ahead for the TMT WFOS project, given the D2

(dis)advantage of seeing-limited and GLAO-assisted UV/Optical observations. WFOS-petite represents,

therefore, the Caltech vision for the way ahead for WFOS on TMT.

The report concludes with 3 Appendices:

i.

A dissertation on VPH gratings as relating to WFOS, by Chris Clemens (UNC) who is a coauthor on the MILES costing study but who also has acted in an advisory capacity for the HIA

team’s WFOS feasibility study - Appendix I (VPH Gratings);

ii.

A theoretical exposition on the combined 3MfR focal-reducer and MILES spectrograph design

by optical design consultant, Damien Jones - Appendix II (Optics Principles);

iii.

A quotation compilation for the MILES optics, taken from several optics vendors who have

demonstrated an interest in the program of work - Appendix III (Competitve Quotes).

Page : 9/108

February 15, 2006

1.1 ACRONYMS AND ABBREVIATIONS

3MfR

ADC

A-G

AO

CALTECH

CaF2

CCD

CoDR

COO

D

DDR

DEIMOS

DL

DM

ELT

FoV

FWHM

GLAO

HIA

IFU

LGS

LRIS

M1

M2

M3

mas

MOAO

n

NIR

PDR

PBS

PSF

PSR

Qld

R

Rslit-width

RfP

RoM

SL

SLGLAO

SNR

SRD

TMA

TMT

UV

VPH

VPHG

WBS

3-Mirror Focal Reducer

Atmospheric Dispersion Corrector

Aplanatic Gregorian (telescope)

Adaptive Optics

California Institute of Technology

Calcium Flouride

Charge-Coupled Device

Concept Design Review

Caltech Optical Observatories

Diameter of Primary Mirror (30m)

Detailed Design Review

Dark Energy Imaging Multi-Object Spectrograph

Diffraction Limit

Deformable Mirror

Extremely Large Telescope

Field Of View

Full-Width at Half Maximum

Ground Layer Adaptive Optics

Herzberg Institute of Astrophysics

Integral Field Unit

Laser Guide Star

Low Resolution Imaging Spectrograph

3MfR’s 1st Mirror

3MfR’s 2nd GLAO Mirror

3MfR’s 3rd Mirror

Milli-arcseconds

Multi-Object Adaptive Optics

Refractive Index

Near-InfraRed

Preliminary Design Review

Product Breakdown Structure

Point Spread Function

Pre-Ship Review

Queensland (Australia)

Spectral Resolving Power

Spectral Resolving Power @ Slit-width (in arcsec)

Request for Proposals

Rough Order of Magnitude

Seeing Limit

Single Laser GLAO

Signal-to-Noise Ratio

Science Requirements Document

Triple-Mirror Anastigmat

Thirty Meter Telescope

Ultra-Violet

Volume-Phase Holographic (grating)

Volume-Phase Holographic Grating

Work Breakdown Structure

Page : 10/108

February 15, 2006

1.2 LIST OF SYMBOLS AND UNITS

This section should provide all the symbols and units that are used in the document with

conversions to SI, if applicable.

m

nm

”

’

º

n

l/mm

microns

nanometers

wavelength

arcseconds

arcminutes

degrees

Refractive Index Modulation

Grating Frequency (lines/mm)

Page : 11/108

February 15, 2006

2. THE MILES CONCEPT

2.1 INTRODUCTION

MILES is a 4-barrel multi-slit UV/optical spectrograph concept designed for the TMT which uses a focal

reducer (the 3MfR system) as a fore-optics relay to increase field of view (FoV), reduce the size of the multislit units and, most importantly, to facilitate ground-layer adaptive optics (GLAO). In almost all observing

conditions the GLAO facility permits enhancement of signal-to-noise (SNR) by concentrating the point

spread function and permitting the use of narrower spectroscopic slits. In the predominant sky-noise limited

regime both increases in SNR and spatio-spectral resolution can be achieved at a level which far outweighs

any small throughput losses that are encountered in the 3MfR fore-optics. Indeed the GLAO facility

envisaged is the simplest imaginable, with a single laser and deformable mirror (DM). The analysis presented

here (in Section 3.3.3 of this costing study) suggests that such a GLAO capability should always be

considered as a part of any ground-based UV/optical spectroscopic or imaging facility.

2.1.1

Compliance with the Science Requirements:

The TMT science requirements document (SRD: v15) defines the Wide Field Optical Imaging Spectrometer

(multi-slit) capability with the following broad attributes:

a.

b.

c.

d.

e.

f.

g.

Wavelength range: 0.31 – 1.0µm (required); 0.3 – 1.3µm (goal)

Field of view: 75 arcmin2 (required), 300 arcmin2 (goal)

Total slit length: ≥ 500”

Image quality: ≤ 0.2” FWHM over any 100nm wavelength interval

Spatial sampling: < 0.15”/pixel (required); < 0.1”/pixel (goal)

Spectral resolution: R0.75 <5000 for 0.75” slit (required); R0.75 <6000 (goal)

Throughput: ≥ 30% from 0.31 – 1.0µm

The MILES concept is compatible with, and is often well in advance of, almost all of the above requirements.

In detail:

a.

b.

c.

d.

e.

f.

Wavelength range: While the MILES concept is depicted here as a single beam

spectrograph accommodating the required 0.31 – 1.0µm wavelength range, there is no

fundamental reason for excluding a multi-beam option to comply with the larger 0.3 – 1.3µm

goal.

Field of view: The design was base-lined at the 75 arcmin2 requirement. Somewhat larger

fields can be accommodated within the MILES concept if some modest compromise to

imagery in the outer field is accepted.

Total slit length: A total slit length of >1,000” is achieved; twice that defined by the

requirements. Further gains in slit length can be accommodated, again at some modest

compromise to imagery.

Image quality: <120mas (FWHM) is achieved for all fields at the input focal plane although

the ADC inevitably degrades this to <190mas in the outer extremities of the field, while the

spectrograph minimally degrades the imagery from input focal plane to detector.

Spatial sampling: The MILES spatial sampling is ~86mas/pixel, assuming a standard 15m

pixel, and hence is compliant with the goal.

Spectral resolution: Assuming VPH gratings (VPHGs) and restricting the camera

articulation angle to 90°, a spectral resolution given by a 0.75” slit, R0.75 ~7000 can be

achieved. Considerably higher resolutions (or commensurately wider spectral coverages) are

achievable with the narrower slits facilitated by GLAO.

Page : 12/108

February 15, 2006

g.

2.1.2

Throughput: Total efficiencies (not including telescope and atmosphere) ≥ 31% are

estimated for all wavelengths. No compromise in throughput is implied by the 3 extra

reflections imposed by the 3MfR system since this allows for larger beam spectrographs that

can accommodate superior blaze efficiencies. This is additional to further substantial SNR

gains implied by the GLAO capability.

Telescope compatibility

Optical designs are presented for an f/1 primary, aplanatic Gregorian (A-G), telescope with an f/15 secondary.

Earlier designs, compliant an f/22 top-end, are also available.

2.2 CONCEPT OVERVIEW

The MILES concept employs a 4-barrel design whose main characteristics are as follows:

1.

2.

3.

4.

The first designs to be studied assumed an f/15 aplanatic Gregorian telescope configuration. The

total field of view was arbitrarily limited to the 75 arcmin2 specification although larger fields and

longer total slit lengths could, in principle, be accommodated through acceptance of some marginal

aberration degradation with field angle.

The full system is deployed in a 4-barrel configuration with each sub-field arm incorporating:

a. an atmospheric dispersion corrector (ADC) of the “trombone” variety placed upstream of the

f/15 telescope focus;

b. an off-axis 3-mirror focal reducer (3MfR) which de-magnifies by a factor of 2 producing an

f/7.5 intermediate focus with a ~4.33’ square (~400mm dia.) field of view. A multi-slit unit

will be deployed at this intermediate focus;

c. the 3MfR design is constrained to image the telescope pupil on its second mirror. Amongst

other things, this facilitates adaptive correction of ground layer turbulence and hence is

referred to here as the GLAO mirror.

d. a dioptric spectrograph collimator with a ~3m focal length delivering a beam-size of ~400mm

adequate for a 0.75” slit resolution R0.75 ~5000, as specified in the SRD. For spectroscopy,

the dispersing element is assumed to be a VPHG, in a transmission Littrow configuration,

feeding an articulated camera whose angle to the collimator optical axis can be adjusted over

at least a 90° range to capture the required spread of spectral dispersions and central

wavelengths. The use of VPHGs and articulated cameras is not fundamental to the design but

is offered as the likely best alternative to optimizing efficiency;

e. a camera with a catadioptric Schmidt-like design operating at f/1.2 and feeding a 2:1 aspect

ratio detector which encompasses the full 4.33’ sub-field of view along its short (slit-length)

axis. In the base-line design the CCD detector is curved to match the curvature of the

camera’s focal surface and would have a format of ~3k-by-6k, given a pixel pitch of 15m

(~86mas on the sky). Design also exists for slightly slower f-ratios that possess a fieldflattener onto a standard CCD package. Detector package vignetting within the camera is

estimated at <4%.

The four sub-fields of the 4-barrel system are distributed in a cross pattern, as shown in Figure 2:1.

We will assume that the instrument is mounted on a TMT Nasmyth platform with its primary

optical axis horizontal. This will require the mechanical design to accommodate significant

changes in gravity vector as the field rotates and will almost certainly involve active flexure

compensation to maintain optical alignment. Tip-tilt actuation of the second (GLAO) mirror in the

3MfR can be used to maintain independent alignment of the four slit modules on the sky.

An isometric view of the full, 4-barrel, instrument (3MfRs plus spectrographs) is shown in Figure

2:2 on the assumption that the optical axis is horizontal. In order to avoid changing gravity

vectors due to field rotation, the primary optical axis could be folded to the vertical at, or near, the

telescope’s Nasmyth focus. However, in this configuration, the upward looking spectrograph

Page : 13/108

February 15, 2006

cameras will obscure the incoming beam as the instrument rotates. In order to avoid this, two

further reflections within the collimator would be required to fold the cameras away from the beam

in a downward looking orientation. The requirement for 3 extra reflections (1 at the telescope

focus and 2 within the collimator of the spectrograph) is at odds with the requirement for optimum

efficiency and hence is currently excluded from further discussion. Furthermore, such a

configuration is likely to increase the required back-focal distance for the telescope.

Page : 14/108

February 15, 2006

ADC foot-print

4.33 arcmin.

individual fields

20 arcmin.

A-G FoV

Figure 2:1 4-barrel layout on f/15 (or f/22) focal plane.

3MfR mirrors

1st

3rd

nd

2 (GLAO)

1 of the 4-barrels

spectrographs

1 of the 4-barrels

3MfRs

f/15 A-G telescope focus

Figure 2:2 Isometric view of f/15 system (as seen from the telescope)

Page : 15/108

February 15, 2006

2.3 THE 3MFR FOCAL REDUCER

2.3.1 Optical Performance

The theoretical basis and detailed design for the 3MfR system is given in Appendix II (Optics Principles), as

supplied by Damien Jones, in the context of the f/15 TMT. The f/15 3MfR prescription, together with its f/22

counterpart, is available on request from Prime Optics, Qld.

A highly satisfactory aberration balance has been achieved with reflective optics which are readily

manufacturable (competitive quotations for all the 3MfR mirrors are given in Appendix III (Competitve

Quotes). Spot plots for representative field positions (Figure 4:13) are compared with the equivalent spots at

the f/15 input focus (Figure 4:12). As can be seen, while the 3MfR images are somewhat “fluffier”, no

overall degradation of image quality, as measured by their rms radii, is apparent while an advantageous

rebalancing of aberrations about the individual sub-field centers is achieved.

2.3.2 3MfR Reflection Losses

Reflection losses in the 3MfR system are mitigated through use of high reflection coatings optimized for the

full 0.31 to 1m wavelength range. Such coatings have been developed at LLNL and have been successfully

deposited on the LRIS collimator for Keck. A new facility will, no doubt, have to be developed in order to

coat larger mirrors however the largest in 3MfR is ~1.2m on a side and hence is about the size of the

suggested TMT primary mirror segments with the advantage that the wavelength range and durability

specification for the coating can be significantly relaxed.

Assuming such coatings, the three reflections will produce losses of <14% broadly uniform over the full

wave-band. Such losses are unavoidable for focal reducers of this type but these are more than compensated

for by activation of the second (GLAO) mirror (Section 2.2.32.3.3). Even without GLAO, a simple tip/tilt

actuation of the second 3MfR mirror would be a major benefit in mitigating wind buffeting and Nasmyth

platform vibration however such gains while quite tangible are difficult to quantify until we have established a

firmer understanding of the mechanical performance of the telescope itself.

2.3.3

The GLAO Capability

If the second 3MfR mirror is changed for an adaptive GLAO deformable mirror then under a broad range of

atmospheric conditions improvements in direct imagery, slit coupling efficiency and resolution, both spatial

and spectral, will be achievable. In quantifying such gains we will assume that the GLAO mirror is

commanded from a Laser Guide Star (LGS) wave-front sensor with a single laser positioned somewhere in

the field of view of each of the 4.33’ sub-fields (four lasers in all). Modeling of such a simple AO

configuration has been performed using the Caltech group’s Arroyo software tool taking atmospheric

turbulence profiles from TMT site testing measurements; a theoretical discussion together with

comprehensive modeling results are given in Appendix B of the original MILES submission which is

summarized in Section 3.3.3. Substantial gains in wave-front error are predicted which indicate that, for

“better-than-median” conditions, much of the energy within the seeing disk will be concentrated into a

~100mas core.

Caveats:

The results presented in Appendix B of the original MILES submission and summarized in Section 3.3.3.

and the conclusions extracted herein are based on state-of-the art modeling using well established code,

however before launching into the results a few caveats are in order:

Page : 16/108

February 15, 2006

The analysis takes as its atmosphere the latest Cn2 measures from TMT site testing. This is unlikely

to be representative of the final site selected but is the best that can be done at this time;

The models assume a perfect adaptive mirror. No account is taken of actuator density or laser

power although conclusions derived for relative large slits (>400mas) are unlikely to be affected;

The models, as yet, do not take account of aberrations in the telescope/ADC/3MfR optical train.

As is demonstrated here, these are comparatively well contained and are not expected to effect the

broad conclusions that are derived.

As expected, GLAO gains in image enhancement are a strong function of seeing, wavelength, field angle and

zenith distance and it is to be expected that the power of such a capability is maximal for field zones centered

around the LGS when observing in the red. Such considerations would argue for modes of operation

whereby narrow (between ~100 and ~400mas) slits are deployed limiting the narrowest to a modest zone

around the LGS. In the following examples we define gain as the ratio between integration times required to

reach the same SNR when compared to a seeing-limited (GLAO-off), 800mas slit, observation. As is

demonstrated in Section 3.3.3.

in poor (25th percentile) seeing, and assuming a fixed ~800mas slit, gains are modest (<20%)

within a ~2’ zone around the laser and actually improve into the UV where the native seeing is

degrading. Outside this zone, and to the corners of the field, a small (<15%) degradation in gain is

experienced;

for median seeing conditions, and assuming now a ~400mas slit, substantial gains (up to ~2) are

predicted over the full 4.33’ field and extending down into the UV for fields with a ~1’ zone.

Outside this zone, and to the corners of the field, substantial (up to ~1.5) gains are experienced, but

in this case, only in the red;

in good (75th percentile) seeing very substantial (up to ~3) gains are made everywhere and at all

wavelengths if the slit-width is again reduced to ~400mas.

Of course such broad summary statements do no justice to an extremely complex parameter space and the full

import of such a GLAO capability requires the detailed exposition as supplied in Appendix B of the original

MILES submission (see also in Section 3.3.3).

It is natural to consider how such a GLAO capability might be used in practice. Of course, many choices can

be made to optimize slit-width to field angle. The very simplest approach would be to use the GLAO-off

condition with ~800mas slits in poor seeing while in good seeing one would use the GLAO-on condition with

~400mas slits irrespective of the wavelength, field angle or zenith distance range. This simple example is

made to bring out another vitally important advantage of GLAO. A reduction by a factor of 2 in slit-width

translates to a factor of 2 in wavelength coverage for a fixed spectral resolution. Even at camera f-ratios as

fast as f/1.2, the unfavorable pixel scale (>9 pixels per 800mas slit) means that wavelength coverage is at a

premium. Hence it is generally the case that a factor of 2 in wavelength coverage translates directly to a

further factor of 2 gain in exposure time.

Spectral and spatial resolution gains will also be compelling. In many instances the narrow slit will convert

into an increase in R which may be adaptively re-binned to enhance final SNR, however, the increased spatial

resolution (recalling the ~86mas pixel-size) will be of benefit in its own right.

It is clear, therefore, that under a large range of observing conditions substantial benefits are to be made from

such a GLAO capability either in required exposure time, spatio-spectral resolution or wavelength coverage

and very often in all three; thus amply justifying any marginal reflection losses that might be experienced in

the 3-mirror 3MfR chain.

Page : 17/108

February 15, 2006

2.3.4 Multi-slit assembly

For ground-based observations, multi-slit masks have almost always been machined either off-line or on

location at the telescope. This is a reliable, if rather inconvenient, costly and cumbersome arrangement which

does not allow for rapid response to changing observing conditions; nor does it allow for the effects of

differential atmospheric refraction to be taken into account. The advantage of machined masks over

mechanical slits is, however, the ability to customize and optimize the mask design for particular target

placements. A good example of using this to good effect is in DEIMOS where the position angle of

individual targets within a field is routinely chosen to optimize sensitivity to rotation curve analysis;

mechanical slits would not allow such freedom. However, in the context of a queue scheduled TMT,

machined slits may be simply too restrictive. The GLAO capability makes an additional compelling case for

mechanical slits, as advocated for NGST in order to facilitate rapid, on-line, selection of slit-widths as a

function of wavelength, position and atmospheric conditions.

(see: http://www.csem.ch/fs/micro_mechanics.htm).

2.3.5 Other benefits of the active GLAO mirror

Not only does the GLAO mirror support the correction of ground layer atmospheric turbulence, it has several

other compelling, although as yet unquantified, capabilities when used simply in low order, tip-tilt mode:

Wind buffeting: Motions of the secondary induced by wind disturbances can be compensated by

tip-tilt actuation of the GLAO mirror. Resonant frequencies in the order of ~10Hz or higher are

well within the practical tip/tilt range of such a 200mm diameter mirror;

Compensation for resonant vibrations of the Nasmyth platform with respect to the telescope can

also be affected;

Differential flexure between the four fields of the 4-barrel system can be accommodated;

Independent fast guiding of the individual fields can be achieved.

A not quite as obvious, but nevertheless very important, capability for the GLAO mirror, is the ability to

correct quasi-static aberrations induced by astigmatism in the ADC “trombone” thus mitigating the otherwise

inevitable image degradation imposed by the ADC prisms. This capability is quantified in Section 2.5.

2.3.6

3MfR Baffling

From the standpoint of secondary mirror wind buffeting there is a clear argument for avoiding telescope

baffles if at all possible. The need for baffles is thought to be most critical to wide-field optical imaging and

spectroscopy since it is necessarily the case that IR instruments will require very effective internal cold stops.

Indeed telescope baffles are generally considered detrimental to IR capabilities.

There is, therefore, a compelling case to be made for rigorously baffling a wide-field optical imager and

spectrograph. While there is generally a pupil stop within a spectrograph’s collimated beam, the addition of

an up-stream pupil stop, supplied naturally within the 3MfR system, will further mitigate ambient light

scattering into the instrument to a degree where telescope baffling becomes unnecessary. Furthermore,

MILES’ spectrographs look into a darkened enclosure rather than directly out into the dome making their

baffling to stray light consequently easier. The job of quantifying such scattering is beyond the scope of this

report, however it is clear that up-stream, fore-optics, baffling within MILES will be of significant benefit in

this context.

Page : 18/108

February 15, 2006

2.3.7

Calibration Sources

The MILES spectrographs are backward looking into a large enclosure that allows for easy mounting of

calibration sources which can directly illuminate the input f/7.5 focal surface of the spectrographs. Without

the 3MfR system all calibration would have to be supplied up-stream of the ADC and hence very far from

focus and difficult to control, requiring a darkened dome for accurate calibration.

2.3.8

3MfR Output Focal Surface:

A further important advantage to the 3MfR concept is that the output image field curvature can be tailored to

match the downstream optics of the spectrograph, as detailed in Appendix II (Optics Principles). The concave

object surface presented to the spectrograph turns out to be ideal for a dioptric collimator and hence allows for

considerably larger beams with consequently more efficient dispersion options. Furthermore, the focal

surface is telecentric compatible with the adaptation to fiber feeds and deployable integral field unit (IFU)

applications should these be required (see SRDv15).

2.4

THE SPECTROGRAPH

2.4.1 Collimator

The 3m focal length collimator consists of two all-spherical fused silica/CaF2 groups (maximum diameter

~480mm), one directly after the input focal surface, the other close to the 400mm pupil. The first of these is

optimized for the full spectral window, from 310nm to 1m, while the second group has two selectable

wavelength-optimized versions, one for the blue (310nm << 560nm) and one for the red (560nm << 1m).

Such a design allows for optimized A/R coatings for the second group (plus camera) and is compatible with a

double-beam spectrograph design where a selection mirror or dichroic is positioned between the two groups.

This arrangement also, of course, allows for optimized detectors. However for simplicity of presentation, we

have chosen to cost the system in a single beam configuration where each wavelength range would be

selected through exchange of the lower collimator group. Indeed such a configuration may be preferred in the

context of a GLAO corrected spectrograph on a queue-scheduled telescope where optimum observing

efficiency is highly wavelength dependent.

2.4.2 Dispersive Elements

With a spectrograph beam size of 400mm, standard surface ruled reflection gratings will have to be mosaiced;

the same is true for VPHGs although monolithic VPH transmission gratings of this size may become

available within a matter of a few years. Either way, grating size is not foreseen as a significant problem.

While VPHGs have obvious advantages (eg: cost, efficiency and blaze tuning) there are no fundamental

optical design reasons for excluding standard reflection gratings apart from the difficulties of producing a well

defined pupil stop – this may be seen as a problem when considering telescope baffling (see Section 2.3.6).

However the proposed camera will support the extra pupil relief necessitated by reflection gratings thus

avoiding the added complexity of camera articulation. The choice will depend on a detailed engineering and

cost benefit analysis which is outside the scope of this report.

Assuming VPHGs: In order to maximize bandwidth, the grating medium (DCG) thickness should be as low

as possible. This in turn imposes an index modulation, n, as high as possible. Current technologies limit n

to >0.2; the following Gsolver simulations conservatively assume a n =0.15. In the analysis used to generate

the blaze efficiencies fringe frequencies are set to a resolution, R0.75 ~4000 and grating thicknesses are

optimized for peak efficiency at 400, 600, and 800nm. In fact, 2 gratings suffice to cover the whole visible

band with efficiency higher than 80%. Example blaze efficiency curves are shown in Figure 2:3 and Figure

Page : 19/108

February 15, 2006

2:4, taken from Clemens Report (Appendix I (VPH Gratings). Each individual curve shows the blaze

function at a given grating angle. The envelope of these curves represent the “superblaze”, the peak of the

blaze at each grating angle.

In these examples the wavelength band encompassed by the detector is everywhere significantly smaller than

the FWHM of the blaze function hence indicating a relatively high average efficiency across the blaze.

However, for spectrographs with smaller beams (say ~250mm) higher fringe frequencies (3000 l/mm in the

blue), larger blaze angles and hence narrower blaze functions are indicated, the combined effect of which is to

significantly decrease overall efficiency. A detailed comparison is required to quantify such losses however it

is more than likely that in many cases these may be comparable with any reflection losses in the 3MfR

system.

Figure 2:3: 3000 l/mm grating necessary to achieve highest resolutions at the UV/blue end of the instrument

bandpass. The curves represent the efficiencies at working angles 33°- 45° (from left to right) in increments of 3°

degrees. The CCD coverage (not shown) is about 50nm at this dispersion. This grating is 5m thick with a 0.035

variation in the refractive index.

Page : 20/108

February 15, 2006

Figure 2:4: Efficiency curves for blue blazed and red blazed 1200 l/mm gratings. The blue lines are angles of 10° 25° for a 5m grating with 0.05 index modulation. The red lines are angles 25° - 40° degrees for a 5m grating with

0.1 index modulation.

2.4.3 Camera

In order to achieve sensible pixel matching for a seeing-limited instrument on such a large telescope very fast

f-ratios, approaching or exceeding f/1 (~100mas/15m-pixels or ~8 pixels/800mas slit) are desirable. In order

to achieve good aberration control in the context a modified Schmidt camera design we have opted to use a

doublet (fused silica/CaF2) aspheric corrector which, when combined with a CCD that is curved to match the

Schmidt’s f/1.2 focal surface, gives adequate performance over the field of view defined by a 3k-by-6-k

detector. Example imaging and spectroscopic spots at various wavelengths and field positions are given in

Figure 4:16 & Figure 4:17. There are two challenges to producing such a camera:

The diameter of the CaF2 aspheric is ~525mm. At an early stage in the project some uncertainty was

expressed in generating such a large piece however we now have several competitive quotes which seem to

confirm their availability. Should such pieces be viewed as too expensive or too high risk, in mitigation, we

would either descope the spectrograph beam size by ~10% and take the marginal hit on slit-width*resolution

product and camera vignetting or redesign for a fused silica triplet corrector. Either way, the SRD

specification will still be readily met.

A curved CCD is a relatively novel feature of the design; however manufacturers and workers in the field (eg:

E2V, UofA’s ITL, UCOLick, JPL – also see: Swain et al. 2004, SPIE 5499) all appear to agree that this will

be possible for a relatively low level of investment. We will, of course, propose a small linked program of

development to study this issue. The impact of retreating to a field-flattened design, if necessitated, is not

considered to be critical.

A camera design issue that has not been addressed relates to the question of the location and cooling of the

CCD. There is no doubt that a 400mm beam Schmidt camera requires a large dewar if the full camera is

going to be cryogenically cooled. While not impossible, some cameras have avoided this by packaging the

detector in their own mini-cryostat. This inevitably increases vignetting and the decision on whether to locate

the CCD externally through the use of a folded Schmidt design remains an option to be studied.

Page : 21/108

February 15, 2006

2.5 THE ATMOSPHERIC DISPERSION CORRECTOR (ADC)

Atmospheric dispersion compensation is either done with counter-rotating Risley prisms or fused silica

prisms which are tromboned; both schemes achieve an approximate match to the dispersion of the atmosphere

and both are widely used (or invoked). Large (~1m) ADCs of both types have been successfully deployed

however they both require to be located a long way (several meters) from focus to be effective; while the

MILES designs have a secondary f/7.5 focus there is simply not enough space in 3MfR to accommodate

ADCs of either type. The only space available is up stream of the telescope focus itself. These considerations

further exacerbate an already serious problem of overall size. Risley prisms based on the fused silica/CaF2

combination cannot be accommodated without mosaicing separate hexagonal prisms which would be very

undesirable and, as a result, the use of trombone ADCs for each individual barrel was studied.

Aberrations induced by the two prisms are unfortunately non-negligible and are exacerbated as the zenith

angle increases and the trombone extended. This can be mitigated by decreasing the prism angles,

necessitating an increase in overall extension. However, as is shown in Figure 2:5 & Figure 2:6, quasi-static

distortion of the second (GLAO) mirror in the 3MfR is able to compensate for much of this effect. On

average, an improvement in FWHM of ~40% is achieved over the field (worst case ~190mas) with almost

perfect compensation at the field center.

Figure 2:5 Spot plots for an f/15 3MfR system with uncompensated ADC at maximum extension (circles are 1”

dia).

Page : 22/108

February 15, 2006

Figure 2:6 Spot plots for an f/15 3MfR system with a GLAO-mirror compensated ADC at maximum extension

(circles are again 1” dia).

2.6

THROUGHPUT

Losses per surface, together with filter, grating and CCD efficiency as a function of wavelength, are given

in Table 2:1. The estimates have been constructed under the following assumptions:

Each column entry is an estimated average over a 100nm waveband;

All three 3MfR mirrors are assumed to be coated using the LNLL “magic” coating as for the LRIS

collimator (see: SRD Appendix 3). The practicality of such coatings on the GLAO mirror has not

been addressed;

Single layer MgF2 coatings have been assumed for broad-band A/R coatings;

A double beam spectrograph is assumed with coatings and CCDs optimized accordingly.

Wavelength (-)optimized coatings are assumed to take an average value of ~0.75% across the

band;

The VPH grating efficiency is taken as 80%. This is well below the maximum predicted from

GSolver models but takes into account manufacturing tolerances, blaze function and grating tuneability;

The detector QE values are taken assuming blue optimized E2V devices and red optimized LBNL

devices.

Page : 23/108

February 15, 2006

Wavelength

Surface

ADC

3MfR

Collimator

A/R coating

(1st group)

A/R coating

(2nd group)

Camera

A/R coating

(corrector)

Mirror

Notes

(nm)

350

450

550

650

750

850

950

4 surfaces

(MgF2)

0.89

0.93

0.95

0.95

0.93

0.92

0.91

3 surfaces

(LNLL)

0.88

0.86

0.86

0.87

0.90

0.89

0.94

0.89

0.93

0.95

0.95

0.93

0.92

0.91

0.97

0.97

0.97

0.97

0.97

0.97

0.97

0.97

0.97

0.97

0.97

0.97

0.97

0.97

0.96

0.96

0.95

0.96

0.95

0.96

0.96

0.96

0.97

0.96

0.96

0.96

0.98

0.96

0.80

0.80

0.80

0.80

0.80

0.80

0.80

0.80

0.94

0.95

0.90

0.80

41%

41%

38%

35%

4 surfaces

(MgF2)

4 surfaces

(-optimized)

4 surfaces

(-optimized)

1 surfaces

(LNLL)

Vignetting

VPHG

Filter

Av. over blaze

Peak

0.80

0.80

0.80

0.80

0.80

0.80

CCD-B

CCD-R

(E2V)

(LBNL)

0.80

0.82

0.88

Total

31%

33%

38%

Table 2:1 Efficiency breakdown as a function of wavelength.

As is clearly indicated, highly competitive throughput is predicted despite the additional 3MfR mirrors.

Any comparison with smaller beam spectrographs which do not require focal reducer pre-optics needs to

factor in the deleterious effects of higher grating frequencies and the lack of a GLAO capability.

2.7 INSTRUMENT LAYOUT, SIZE AND WEIGHT:

We have opted for a configuration which retains the primary optical axis in the horizontal plane. To fold

to the vertical will require 3 extra reflections (1 at the telescope f/15 focus and 2 within the collimator of

the spectrograph) and is likely to increase the required back-focal distance for the telescope. A horizontal

axis will require the mechanical design to accommodate significant flexure as the instrument rotates and

will almost certainly involve flexure compensation mechanisms to maintain optical alignment. Tip/tilt

actuation of the GLAO mirror in the 3MfR can be used to maintain independent alignment of the 4 slit

modules on the sky.

The full 4-barrel configuration is shown in Figure 2:2 and the following 2 figures (Figure 2:7 & Figure

2:8):

Page : 24/108

February 15, 2006

f/15 A-G telescope focus

Articulated cameras

Figure 2:7 Side view

Separate lens group

optimized for blue and red

Space for ADCs

Page : 25/108

February 15, 2006

GLAO

mirror

3MfR

1st mirror

Articulated

cameras

Spectrograph

Figure 2:8 Rear View (towards telescope).

2.7.1 Weight/Space budget

Overall dimensions: 9m x 5.3m diameter (excluding ADC)

Spectrograph dimensions: 4.8m x 700mm diameter (each)

Focal reducer glass weight: ~980 lbs x 4 = 3920 lbs x 5(scaling factor) = 19600 lbs.

Spectrograph glass weight: ~595 lbs x 4= 2380 lbs x 10(scaling factor) = 23800 lbs.

Total weight estimate: 43,400 lbs (~20 tons)

Page : 26/108

February 15, 2006

2.8

CONCLUSIONS:

The design of a wide-field UV/optical multi-slit spectrograph for the TMT has been presented with the

following characteristics:

The system is fully compliant in field of view, spectral resolution and throughput with the SRD

requirements;

Yet larger fields of view are achievable as an extension of the conceptual design at the cost of

some marginal degradation in performance at the extremes of the field;

A range of A-G telescope configurations, from f/15 to f/22, are achievable. R-C telescope

configurations are unlikely to be within the scope of such designs;

Quotes are in for the aspheric mirrors while the sizes of the large CaF 2 components are within

achievable bounds;

GLAO and tip-tilt correction of the 4 individual fields is achievable through activation of the

second 3MfR focal reducer mirror. Significant gains in SNR, exposure time and wavelength

coverage are indicated for almost all wavelengths and observing conditions.