SKF3323 - Faculty of Chemical Engineering, UTM

advertisement

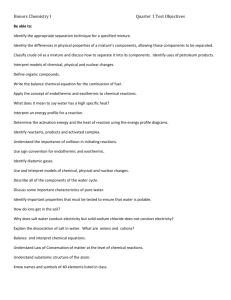

COURSE OUTLINE Department & Faculty: Department of Chemical Engineering Faculty of Chemical & Natural Resources Engineering Subject & Code: Separation Processes I (SKF 3323) Total Lecture Hours: 3 hours x 14 Weeks Page 1 of 3 Semester: 2 Academic Session: 2005/2006 Lecturer Room No. Tel. No. E-mail : : : : Section Meeting Time Venue Assistant : : : : Prerequisite : Synopsis : This course introduces the various types of separation processes involved in the chemical and other physical processing industries such as evaporation, absorption, distillation, liquid-liquid extraction and solid-liquid extraction (leaching). It also deals with design and simulation of separation operations using mass transfer principles. All of the topics is illustrated by detailed examples and is accompanied by at least three assignments. Learning Outcomes : By the end of the course, students should be able to: 1. Describe and differentiate the various separation processes 2. Classify the different types of separation mechanism 3. Identify basic principles of separation mechanism 4. Calculate the design parameters of separation equipments 5. Analyze the performance of the separation equipments Generic Skills Addressed : Prepared by: Name: Signature: Date: 1) 2) 3) 4) 5) Lifelong Learning (LL1 – LL3) Problem Solving (CR1 - CR4) Communication Skills (CS1 – CS4) Teamworking (TW1 – TW5) Self-esteem (SE1 – SE4) Certified by: (Course Coordinator) Name: Signature: Date: COURSE OUTLINE Department & Faculty: Department of Chemical Engineering Faculty of Chemical & Natural Resources Engineering Subject & Code: Separation Processes I (SKF 3323) Total Lecture Hours: 3 hours x 14 Weeks Week 1 Topic Introduction to Separation Process Industrial chemical processes Mechanism of separation Selection of separation processes Page 12ofof33 Semester: 2 Academic Session: 2005/2006 Learning Outcomes It is expected that students will be able to: explain the importance of separation process identify and describe classical separation methods 2&3 Evaporation Types of evaporation equipment and operation methods Calculation methods for - Single-effect evaporators - Multiple-effect evaporators It is expected that students will be able to: identify the different types of evaporation equipment and operation methods design single-effect and multipleeffect evaporators 4&7 Gas-Liquid Separation Processes Types of separation processes and methods Equilibrium relations between phases Continous humidification processes Absorption in plate and packed towers - dilute and concentrated mixtures Estimation of mass-transfer coefficients for packed towers It is expected that students will be able to: identify and use the relevant equilibrium relationship distinguish between plate and packed towers design cooling and absoption towers estimate the mass-transfer coefficients for packed towers 8 & 12 Vapour-liquid separation processes Equilibrium relationship Simple distillation methods Binary fractional distillation using - McCabe-Thiele method - Enthalpy-concentration method Multicomponent distillation It is expected that students will be able to: identify batch distillation and continous fractional distillation design simple batch distillation apply the McCabe-Thiele and Enthalpy-concentration graphical methods for a given separation apply Fenske-Underwood-Gilliland correlation in multicomponent column Liquid-liquid Extraction Types of equipment Phase equilibrium relationship Single-stage liquid-liquid extraction Continous multistage countercurrent liquid-liquid extraction It is expected that students will be able to: identify the most common types of equipment used for liquid-liquid extraction plot extraction equilibrium data on right-triangular diagrams compute equilibrium-stage requirements of - single countercurrent extraction - multistage countercurrent extraction 13 COURSE OUTLINE Department & Faculty: Department of Chemical Engineering Faculty of Chemical & Natural Resources Engineering Semester: 2 Academic Session: 2005/2006 Subject & Code: Separation Processes I (SKF 3323) Total Lecture Hours: 3 hours x 14 Weeks Module 14 Topic Liquid-solid leaching Equipments for liquid-solid leaching Single-stage leaching Countercurrent multistage leaching Teaching Methodology Page 13ofof33 Learning Outcomes It is expected that students will be able to: identify the most common types of equipment used for leaching compute equilibrium-stage requirements of - single countercurrent leaching - multistage countercurrent leaching : Lectures and Tutorials References : Students are required to purchase the text book and are strongly advised to refer to at least one of the following references: 1. “Transport Processes and Separation Process Principles 4 th Ed.” by Geankoplis 2. “Separation Process Principles” by Seader and Henley. 3. “Unit Operations of Chemical Engineering 5th Ed.” by McCabe, Smith and Harriott. Regulations : Students are required to attend all lectures. Attendance will be taken. Assessment : Assignments and quizzes Test I Test II Test III Final Examination Total 10% 10% 10% 20% 50% 100%