Form 20 - Heriot-Watt University

advertisement

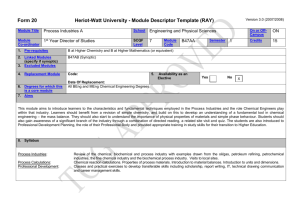

Form 20 Version 3.0 (2007/2008) Heriot-Watt University - Module Descriptor Template (RAY) Module Title Separation Processes A School Engineering and Physical Sciences Module Co-ordinator 3rd Year Director of Studies SCQF Level 9 1. Pre-requisites B48BB Process Engineering A 2. Linked Modules (specify if synoptic) 3. Excluded Modules B48CD Separation Processes B (Synoptic) 4. Replacement Module Code: 5. Module Code Semester B49CA Availability as an Elective Yes 1 No On or OffCampus ON Credits 15 X Date Of Replacement: 6. Degrees for which this is a core module 7. Aims All BEng and MEng Chemical Engineering Degrees The aim of this module synoptic set is to introduce separation of mixtures, where process is dictated by either an equilibrium condition or a rate of transfer. This first module in the synoptic set deals with liquid systems and covers the application of theory to the design and operation of key unit operations, including distillation, liquidliquid extraction, gas absorption and evaporation. Practical experiments reinforce subject matter covered with learning materials. 8. Syllabus Fundamental concepts in mass transfer, particularly two-film models, film and overall MT coefficients. Determination of local MT rates. Correlations for MT coefficients and similarities between heat and mass transfer. Liquid-liquid extraction: equilibrium data for immiscible and partially miscible systems. Stage calculations for single-stage, cross-flow and countercurrent systems. Binary distillation: continuous distillation (column configuration, condensers, reboilers). McCabe-Thiele approach for binary systems. Total, minimum, and optimum reflux. Effect of feed thermal condition, product specifications and relative volatility. Sidestreams and multiple feeds. Binary batch distillation (single stage, multi-stage). Evaporation: types of evaporators. Multi-effect evaporators and their arrangement. Evaporator sizing calculations. Steam economy. Condensing and vacuum equipment. Design of packed contacting columns: height and number of transfer units, concentrated and dilute applications. Minimum liquid flow rate, operating lines. Methods for determining the number of transfer units. Determining HTU values. Heat effects – isothermal, adiabatic treatments. Hydraulic design of packed and plate columns: types and configurations of internals, pressure drop and hold up characteristics. Form 20 Version 3.0 (2007/2008) Heriot-Watt University - Module Descriptor Template (RAY) Module Title Separation Processes A School Engineering and Physical Sciences Module Co-ordinator 3rd Year Director of Studies SCQF Level 9 Module Code B49CA Semester 1 On or OffCampus ON Credits 15 9. Learning Outcomes (HWU Core Skills: Employability and Professional Career Readiness) Subject Mastery Understanding, Knowledge and Cognitive Skills Scholarship, Enquiry and Research (Research-Informed Learning) Personal Abilities Apply principles of equilibrium and material balances to the sizing of typical process unit operations; distillation, liquid-liquid extraction systems. Understand the limitations imposed for processes which are dictated by rate of transfer; absorption columns. Describe interconnected mass and heat transfer processes, e.g. evaporation, flash separation, mathematically. Solve the equations developed. Apply design procedures for a range of unit operations: distillation, absorption, adsorption, liquid-liquid extraction. Develop knowledge of evaporator types and other related equipment. Be able to perform basic evaporation calculations. Appreciate the differences between single effect evaporation and multi-effect evaporation and know when and why to use multi-effect evaporators. Industrial, Commercial & Professional Practice Autonomy, Accountability & Working with Others Communication, Numeracy & ICT 10. Assessment Methods Method Examination Coursework Increase awareness of the theory behind key separation operations. Develop skills in mathematical analysis of physical phenomena to generate mathematical equations to ease the design of separation process equipment. Acquire knowledge of the industrial practices relating to key unit operations. Work in small groups on specific technical problems in the separations area and demonstrate proper use of the appropriate tools to solve problems. Demonstrate competency in reporting findings and relating them to other learning material. 11. Re-assessment Methods Duration of Exam (if applicable) 2 hours Weighting (%) Synoptic modules? 70% B49CD Method Duration of Exam (if applicable) 30% Examination (synoptic with B49CD) Coursework 3 hours 12. Date and Version Date of Proposal 29 Feb 2008 Date of Approval by School Committee Date of Implementation Version Number 1.0