Rare Earth Element Separation: Techniques & Options

advertisement

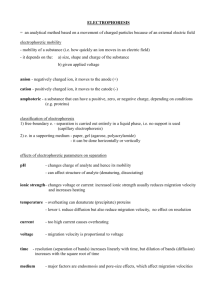

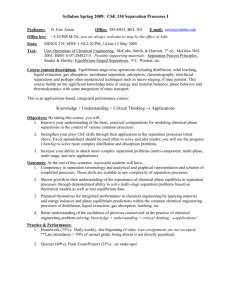

OPTIONS FOR THE SEPARATION OF RARE EARTH ELEMENTS J.R. Goode J.R. Goode and Associates, Suite 1010, 65 Spring Garden Ave., Toronto, Ontario, Canada, M2N 6H9 (jrgoode@sympatico.ca) ABSTRACT This paper reviews options for the separation of a mixture of rare earth elements (REE) into its component elements. The original crude separations used selective chemistry such as double salt precipitation and reductive/oxidative processes - methods that still have a place in the industry. Fractional crystallization was developed for more complete separations of adjacent REE. The latter method was replaced by ion exchange (IX) which was in turn replaced by solvent extraction (SX). Two main SX chemistries are in use (solvation and cation exchangers) with several variants (mixed solvents, ionic liquids, etc.) under development. Plant configurations have evolved including advanced techniques like “hyperlinking”, novel saponification methods, and alternative stripping techniques. The classic mixer settler is the most commonly employed device although centrifugal contactors are also used. Nondispersive SX options, including microfluidic devices and membrane-assisted SX techniques, are being developed and could revolutionize the SX option. Other REE separation techniques now being studied, and discussed in this paper, include Molecular Recognition Technology (MRT) and Free Flow Electrophoresis (FFE), and newer ion exchange based separation systems. Separation plant feed composition, purity targets, separation system chemistry, reagent demands, environmental issues, control systems, and economics are compared and discussed. KEYWORDS Rare earth separation, solvent extraction, SX, solvent, mixer-settler, centrifugal contactor, non-dispersive SX, microfluidics, membrane supported SX, Molecular Recognition Technology, MRT, Free Flow Electrophoresis, FFE, environment, economics