solvents extraction

advertisement

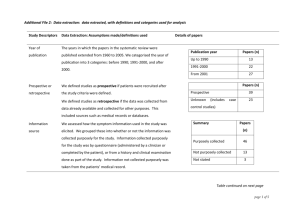

Optimisation and modelling of the enzymatically assisted aqueous extraction of gac fruit oil 1,2 H. C. Mai, 2H. M. Le, 1V. Truong, 2F. Debaste Nong Lam University, Department of Chemical Engineering, Thu Duc district, Ho Chi Minh City, Vietnam; 2Université Libre de Bruxelles, Transfers, Interfaces and Processes Department – Chemical Engineering Unit, av. F.D. Roosevelt 50, CP 165/67, 1050 Brussels, Belgium; Tel.: +32 26506756, E-mail: fdebaste@ulb.ac.be. 1 Momordica cochinchinensis Spreng (Gac) fruit is a traditional village fruit in Vitenam which contains anti-oxidants ( -carotene, lycopene) in extraordinarily high amounts, approximately ten time higher than vegetables already known for their high anti-oxidants content (Vuong, 2000), making it an interesting and potential natural source of lycopene, carotene and colour for the food and pharmaceutical industries. As carotenoïds are mainly lipophilic, these molecules tend to concentrate in the oil contained in the gac fruit. Therefore, extraction of the carotenoïds can be achieved by beginning with the extraction of the oil mainly present in the fruit arils. This oil can further be treated to extract the carotenoïds, or can be directly sold on local or international markets. Multiple extraction processes with organic solvent have been developed (Kubola et al., 2011) to efficiently extract this oil and its carotenoïd content. Yet, in the scope of food production, those solvent should be avoided. Enzymatically Assisted Aqueous Extraction (EAAE) is an efficient alternative to the use of those solvents. In this work it is proposed to study EAAE aiming a further development of a scaled-up process. To reach this goal, it is proposed to study experimentally the EAAE of gac oil, to optimize this extraction using surface respond methodology and to propose a first phenomenological model for the extraction kinetic. This model will be a convenient tool for process scale-up. Experimental test for extraction were realized in continuously stirred batch by putting in contact shredded gac arils with water and pectinolitics enzymes for a given time with. The following parameters were varied: contact time (from 10 min to 6 hours), liquid/aril mass ratio (from 6 to 60), enzyme/aril mass ration (from 1/10 to 1/3), temperature (from 45°C to 55°C), agitation speed (from 100 to 200 rpm), initial state of the gac aril (time from fruit opening, dried or fresh samples). Extracted mass of oil after centrifugation and total carotenoïd content of the oil were evaluated. All the data related to the final extraction quantities are analysed using statistical tests (multiple way ANOVA) and surface respond methodologies. Moreover, samples were analysed at regular time during some experiment to measure a kinetic of extraction. The proposed kinetic model is based on a mass balance on oil quantity extracted from the gac aril assuming that this extraction procedure is limited by enzymatic degradation of the pectin. Considering a Michaelis-Menten law for the degradation, this leads to the following expression for the extracted oil quantity H(t) (kg oil/kg of solution) (1) where Hmax (kg oil/kg of solution) is the oil quantity in solution for which the driving force of the extraction would be null. H0 (kg oil/kg of solution) is the quantity of oil would be extracted instantaneously (compared to the total extraction time) at the begining of the extraction. a and b are adjustable parameters obtained by the combination of multiple physical parameters. a is an indicator of the first order part of the reaction speed while b is correlated to the saturation term of that kinetic. The values of H0, a and b are fitted using least-square regression. The main results of the experimental results analysis are: the total amount of oil extracted is about 0.2 kg oil/kg gac aril, which is of the same order of magnitude as what was reported using organic solvents (Kubola et al., 2011) for the given precision of the total carotenoïd content measurement, this concentration in the extracted oil seems to be constant and independent of the process parameters. to achieve a good reproducibility of the results of fresh aril, the time between aril shredding and extraction should be maintain under 2 days. 40 % in mass more oil can be extracted from dried arils than from fresh aril. the lowest quantity of enzymes offer the fastest kinetics but has no impact on the final amount of oil extracted. heating fasten the extraction but has no measurable impact on the quantity of extracted oil. A typical result of the kinetic measurement is presented on Figure 1 where the mass of extracted oil from dried gac arils is presented. Equation (1) with least-square best fitting parameters value is also presented. The quality of the fitting is encouraging, yet, as 3 parameters were fitted, the power of extrapolation of this model is still limited. Figure 1: mass of extracted oil as a function of time In this study, the EAAE of gac oil was presented and partially optimized, leading to yield comparable to those obtained using organic solvents. A first promising model was written to be a base for a rational scale-up strategy. References: J. Kubola, N. Meeso, S. Siriamornpun, Lycopene and beta carotene concentration in aril oil of gac as influenced by aril-drying process and solvents extraction, Food Research International, Corrected proofs, 2011, doi:10.1016/j.foodres.2011.07.004 L.T. Vuong, Under-utilized beta-carotene-rich crops of Viet Nam, Food and Nutrition Bulletin, 2, p. 173–181, 2000.